Komodo Hobby

www.komodohobby.com

1

Introduction

Congratulations on your purchase of KH-283 Outrunner Motor Kit Version 2. KH-283 V.2 is a modified

motor kit designed for powering 3D and Aerobatics RC airplanes. Modelers can choose either back

mount style or stick style to meet the airplane requirement.

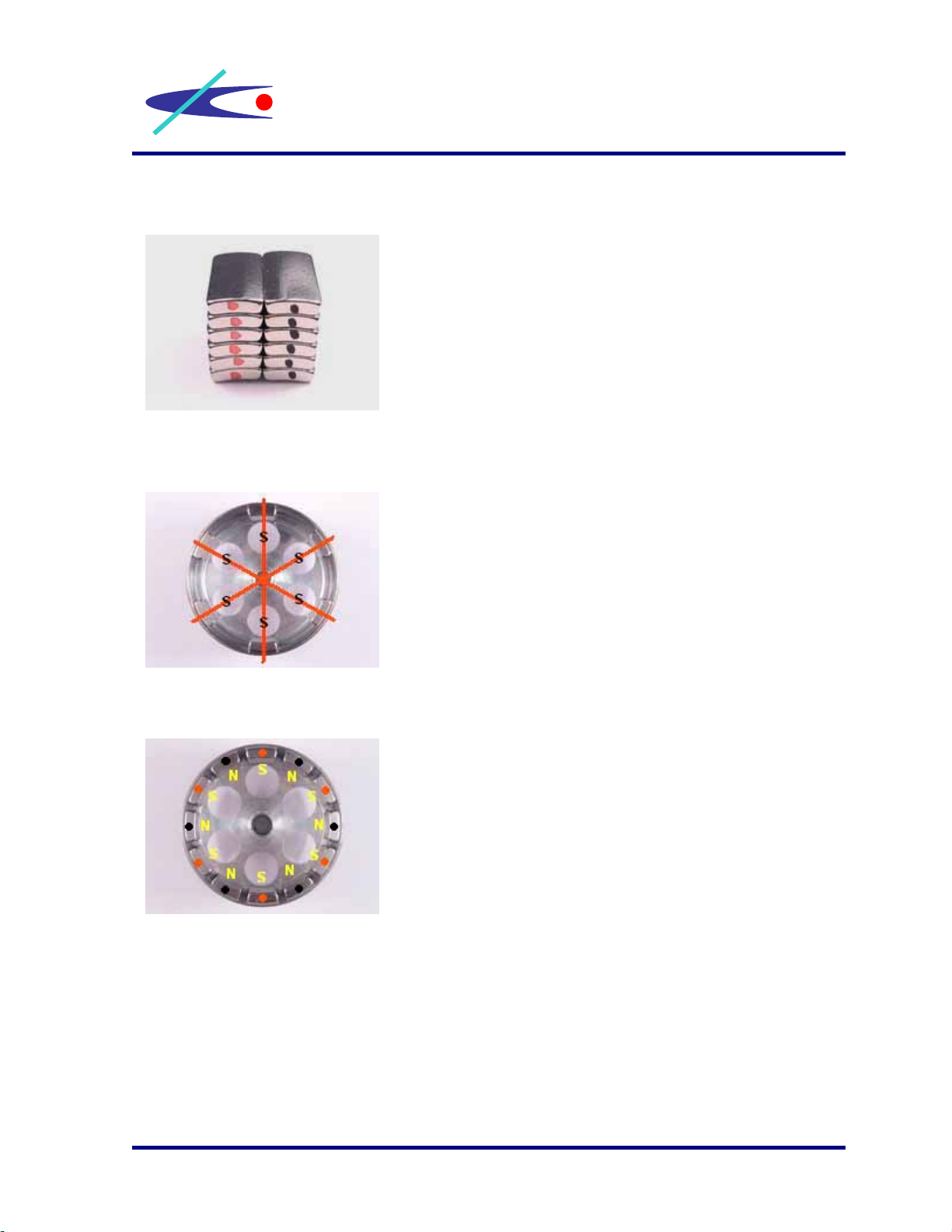

KH-283 V.2 powered with 2mm thickness curved NdFeB magnets. It delivers excellent acceleration for

hovering and performing aggressive 3D aerobetic maneuvers. By the latest design of 9 degrees

magnet gap, the motor can be started-up and run smoothly.

KH-283 V.2 motor kit includes high quality hardened steel main shaft and pre-assembled precision

end-bell and flux ring. Those parts are produced by advanced technology. It allows the motor running

at high rpm without vibration. Motor builders can utilize three-screw lock system to install and change

main shaft without gluing. If you are a serious motor builders or modelers, Komodo Outrunner Motor kit

is the only choice for you.

Warning

Radio Control Model and Outrunner Motor Kit are not toy!!! It contains sophisticated small parts and is

designed for hobby use only. All parts of this outrunner motor kit have to be assembled and operated

with great care. Outrunner motor can produce very high power to turn gear or spin propeller. It is

capable of causing property damage and all bodily harm to operator or spectators. If you are a

beginner of motor builder, please seek assemble and operational help from experienced motor builder.

Be caution!!!

If this outrunner motor kit is not assembled and operated properly, it can destroy your electronic speed

control, receiver, batteries and relevant equipment completely.

Parts List

(QTY) Items

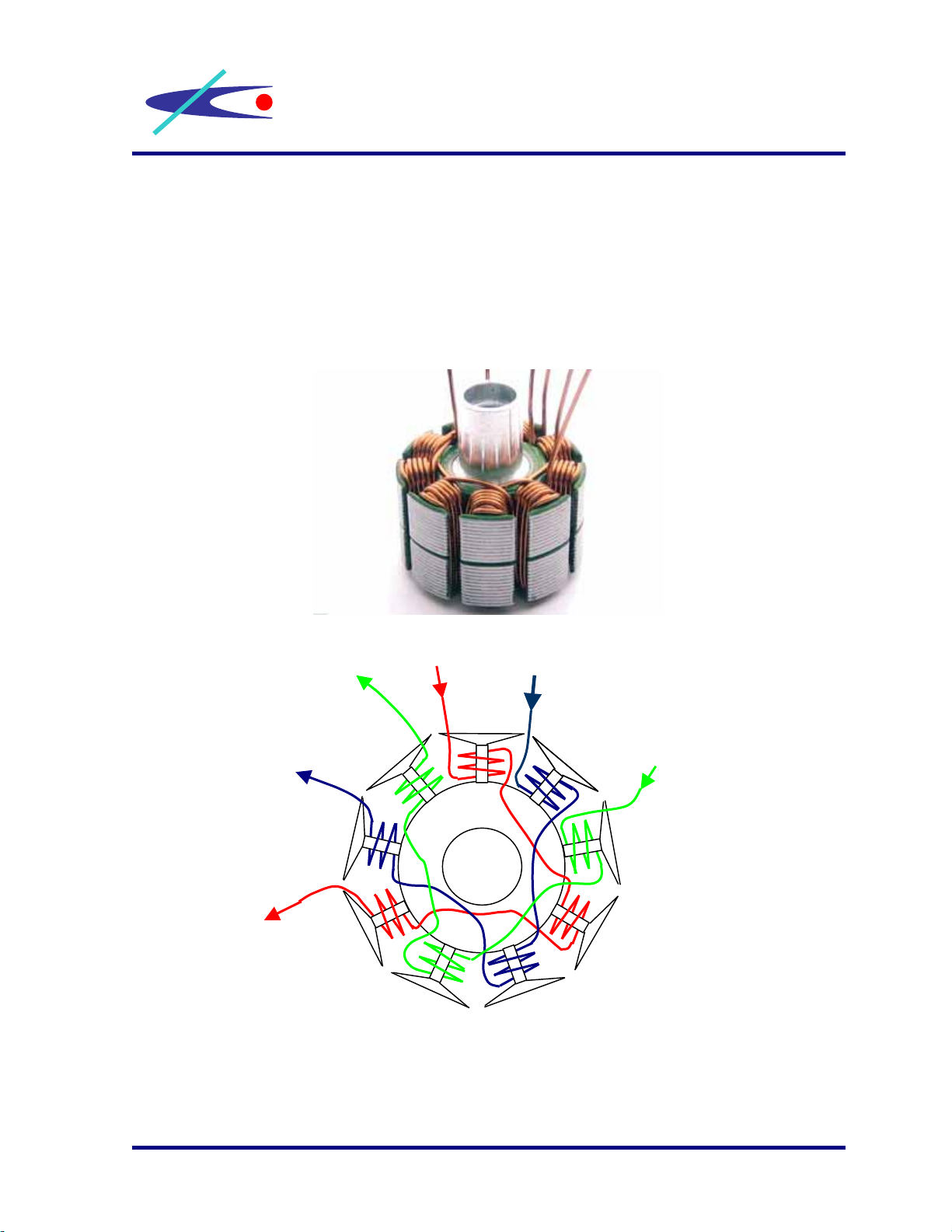

(1) Pre-pressed End-Bell and Flux Ring

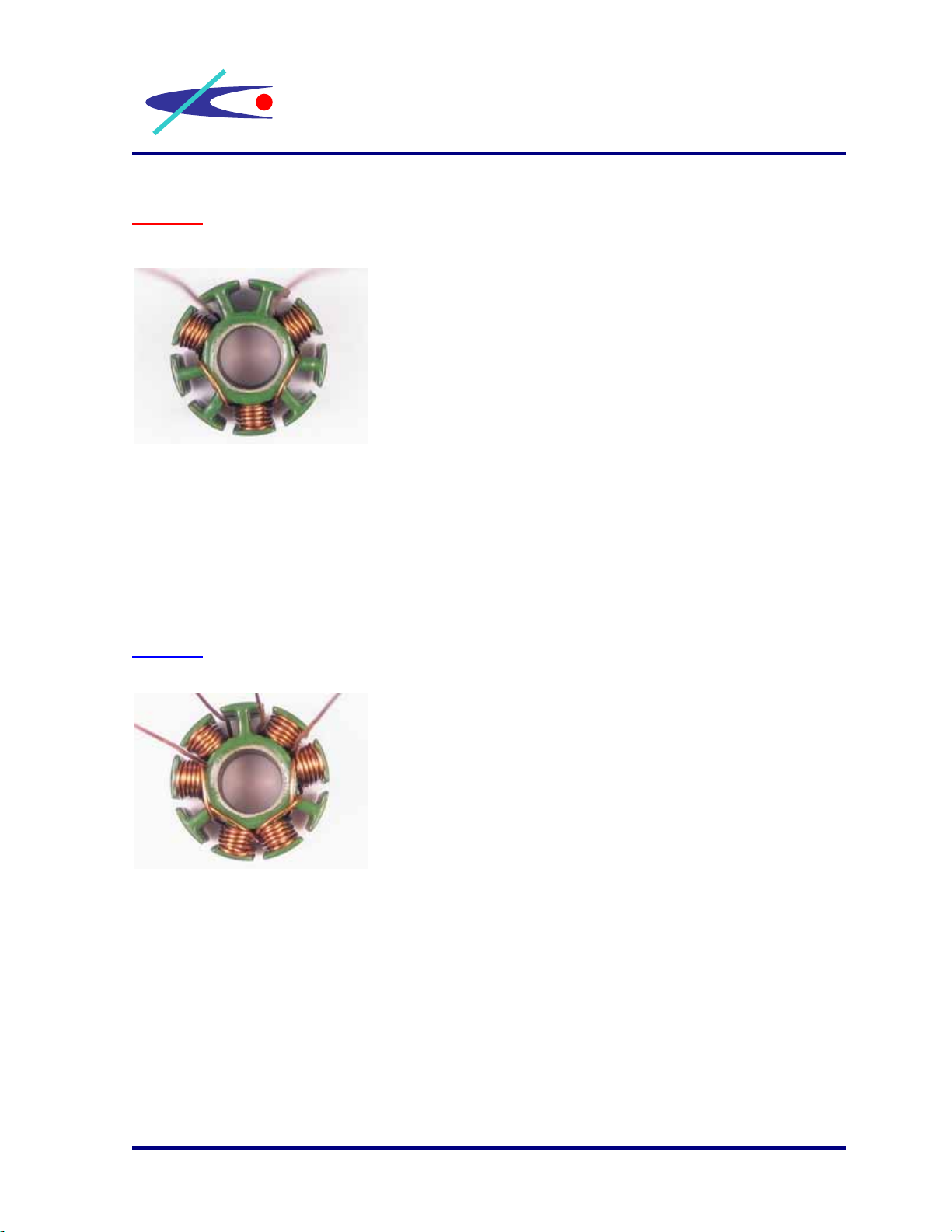

(2) 23.8mm Stator

(2) Ball Bearings

(1) 3.17mm Hardened Steel Shaft

(1) 40feets, AWG 23 Enameled Magnet Wire

(12) NdFeB Curved Magnets

(1) Propeller Saver

(2) Propeller Saver Replacement Rings

(1) O’ring

(3) Connector Pairs (Male and Female)

(7) Shrinking Tubes

(3) M3 x 4 Screws

(2) M3 x 8 Screws

(1) C-Clip

(1) Bearing Tube