2

Contents

Introduction......................................................................................................... 3

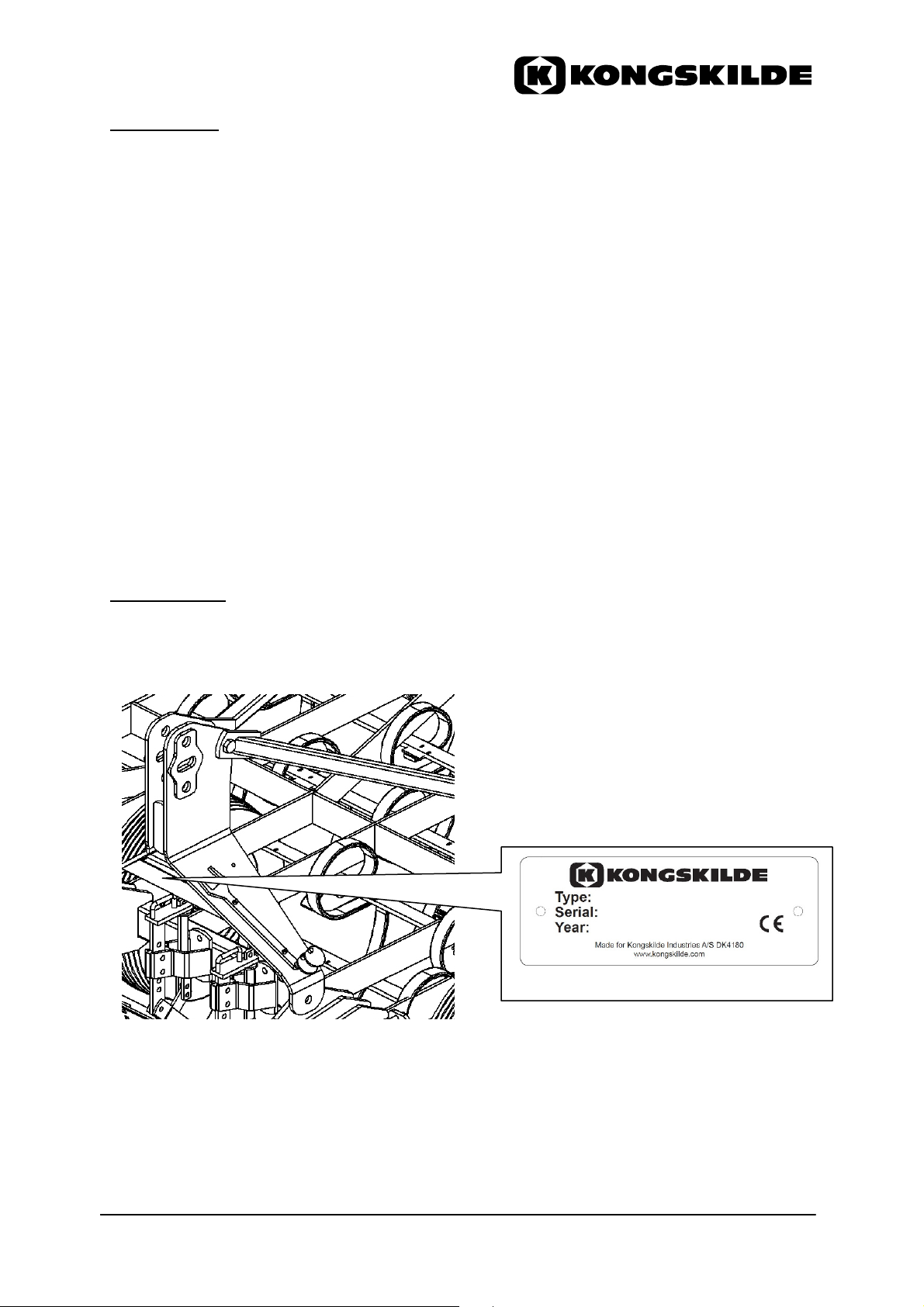

Identification ....................................................................................................... 3

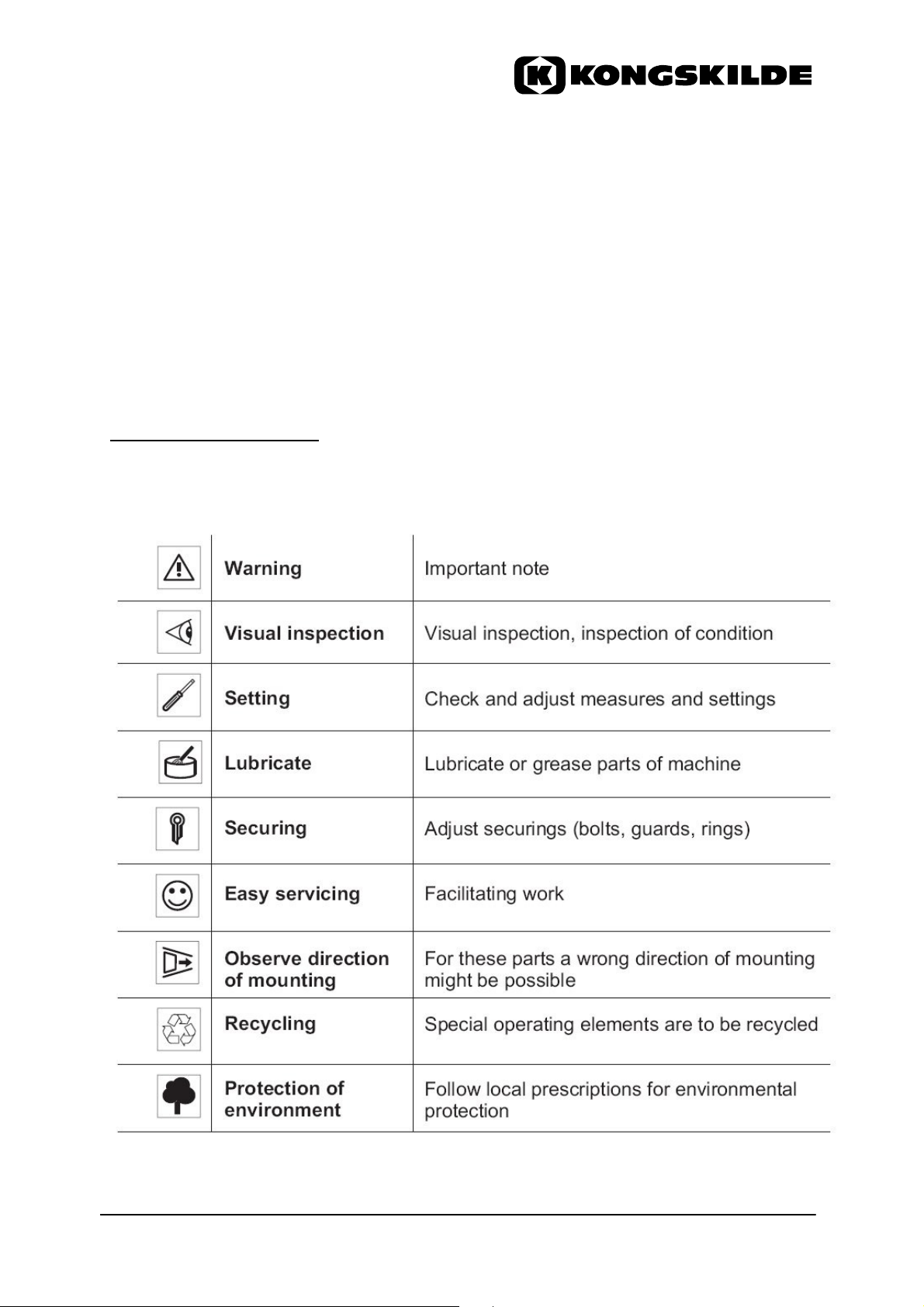

Explanation of symbols ..................................................................................... 4

Safety................................................................................................................... 5

General safety advice..................................................................................... 5

Coupling and uncoupling................................................................................ 5

Three point hitch or linkage ............................................................................ 6

Operation ....................................................................................................... 6

Transportation by road/transport .................................................................... 6

Before driving ................................................................................................. 7

During transportation...................................................................................... 7

After transportation......................................................................................... 7

Maintenance .................................................................................................. 8

Safety decals.................................................................................................. 9

Technical data and dimensions ...................................................................... 11

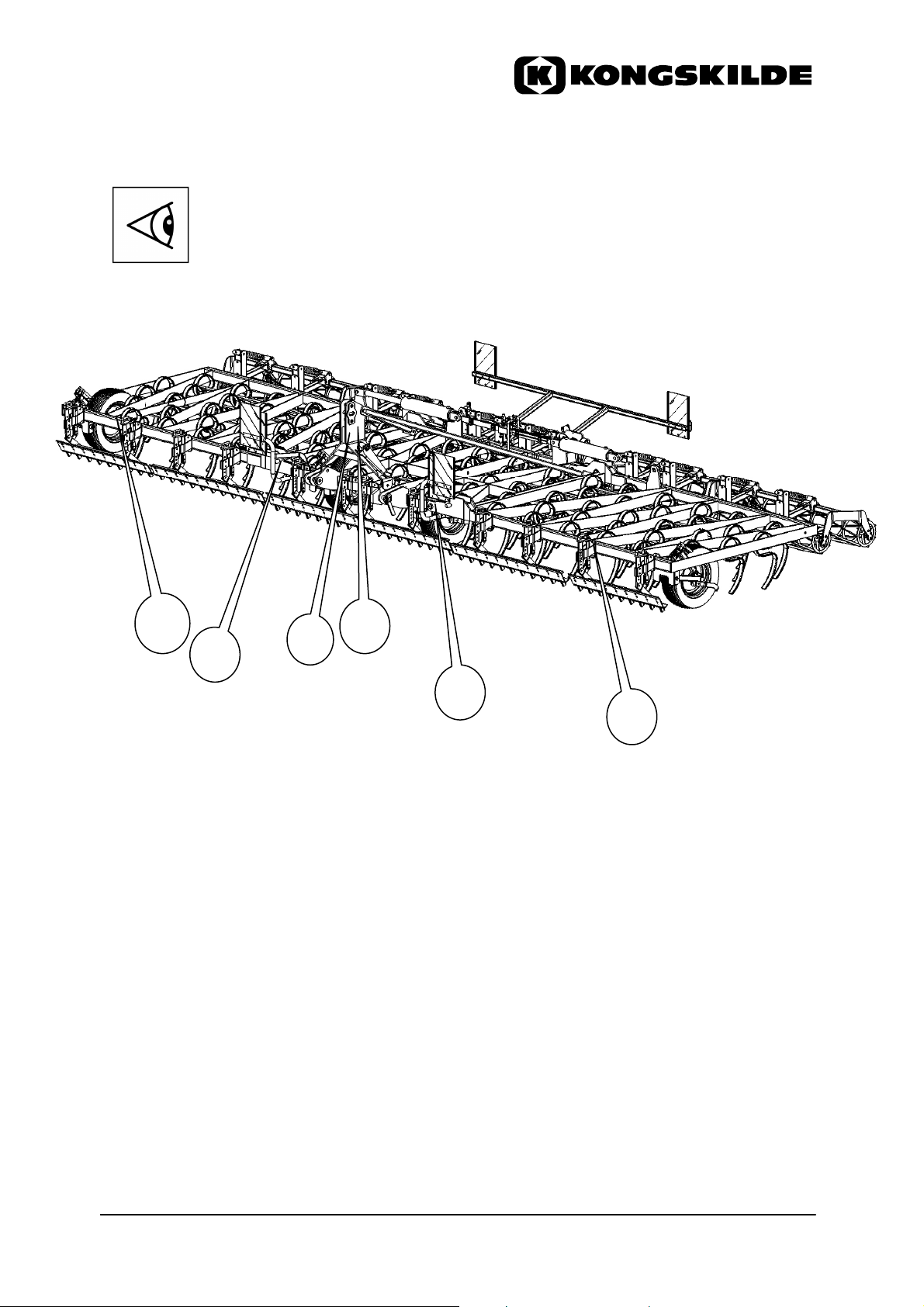

Lifting points………………………………………………………………………… .12

Operation........................................................................................................... 13

Coupling ...................................................................................................... 13

Uncoupling ................................................................................................... 14

Adjustment of top link................................................................................... 14

Folding and unfolding with mechanical wing lock system...............................15

Folding and unfolding with automatic wing lock system..................................16

Preparing for road transport ........................................................................ 16

Adjustment and use of Vibro Master 3000 ..................................................... 17

Adjustment of the cultivator working depth .................................................. 17

Adjustment of the level board....................................................................... 18

Adjustment of the rear rollers (parallelogram) .............................................. 19

Adjustment of the long finger rear harrow .................................................... 20

Turning......................................................................................................... 21

Reversing ..................................................................................................... 21

Maintenance...................................................................................................... 22

General ........................................................................................................ 22

Tyre pressure ............................................................................................... 22

Lubrication.................................................................................................... 22

Warehousing and storage................................................................................ 23