2

Index

Introduction: .......................................................................................................................3

Pre Assembly Instructions ..................................................................................................4

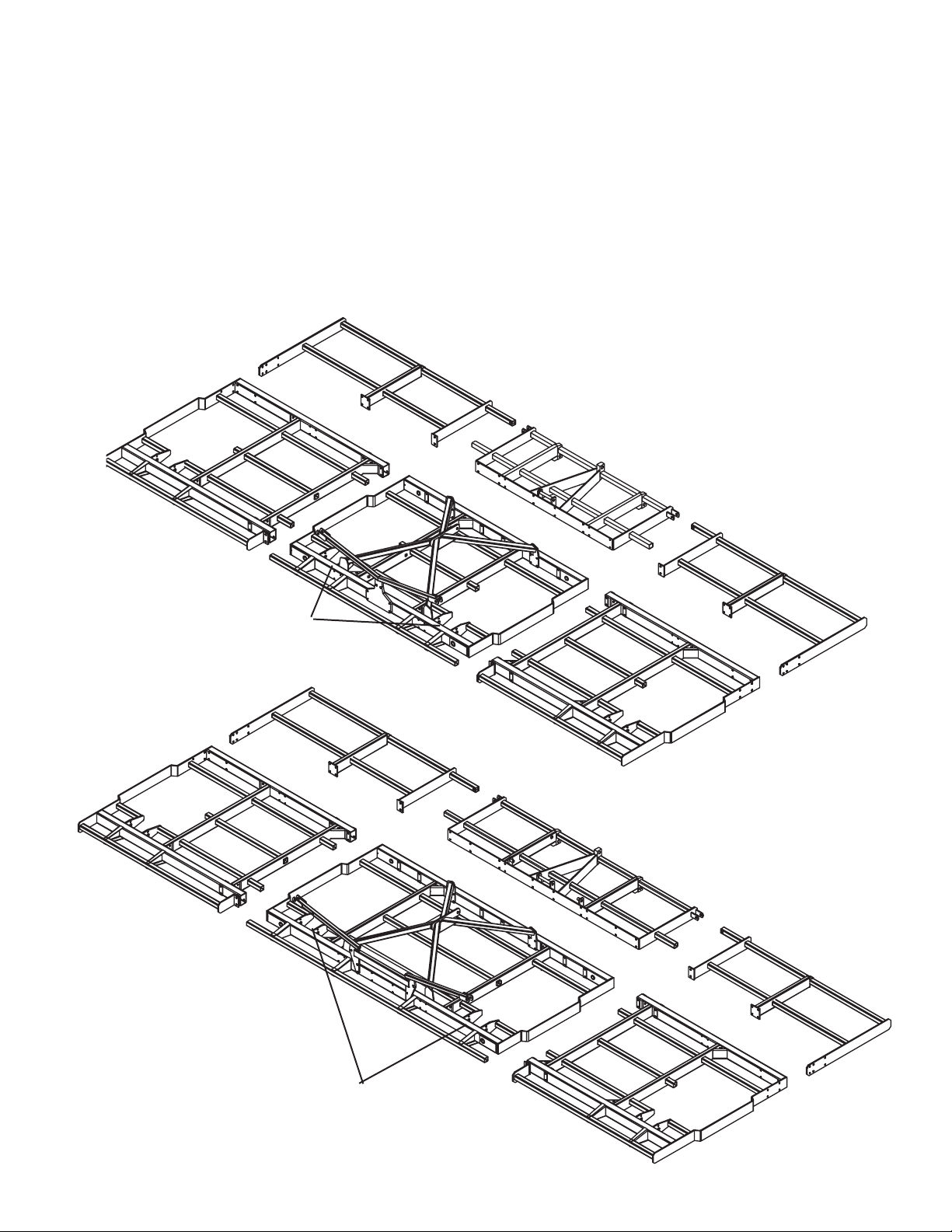

Frame Sections ...................................................................................................................5

Tine Locations: ..................................................................................................................6

Hardware Organization: .....................................................................................................7

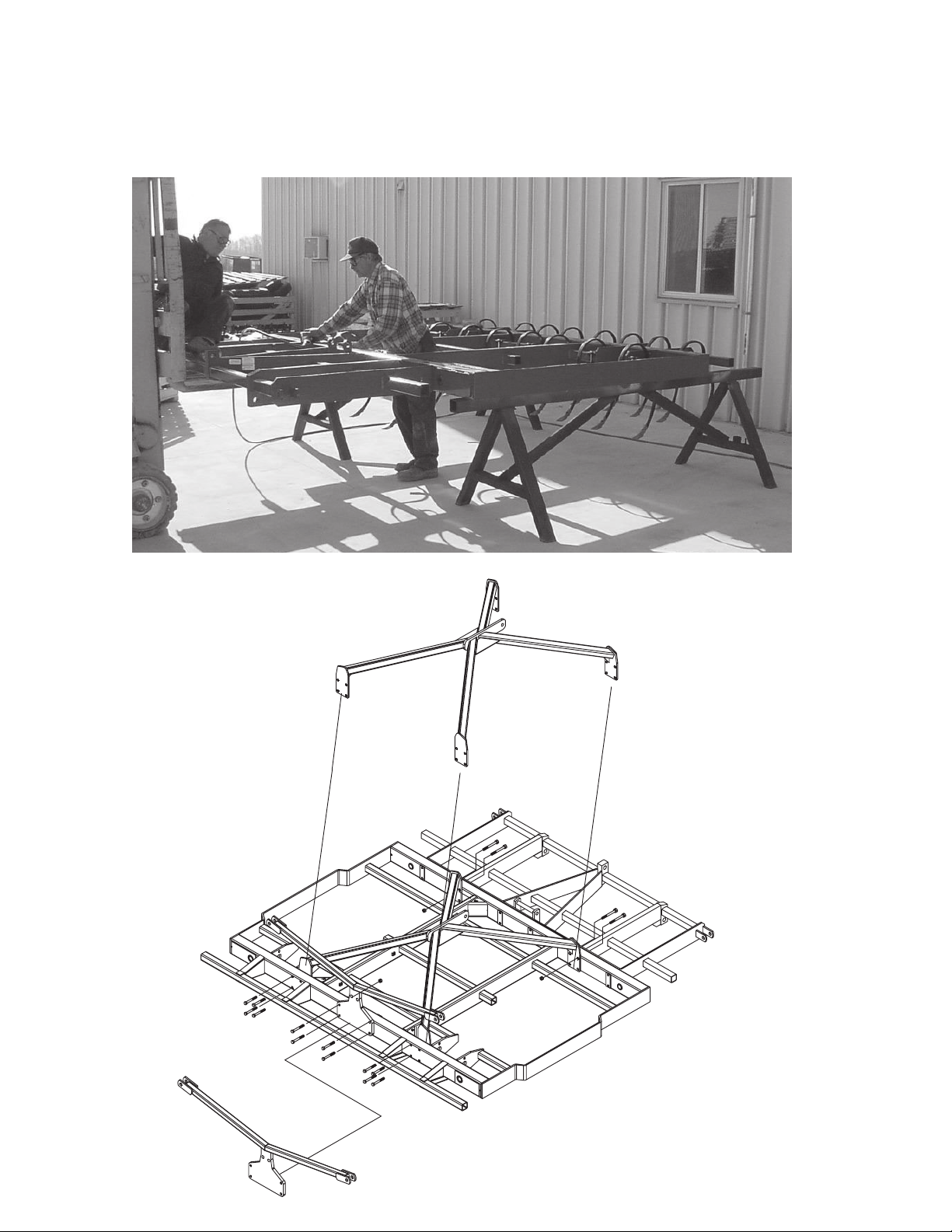

Frame Assembly: ...............................................................................................................8

Self Levelling (Narrow Center): ........................................................................................9

Self Levelling (Wide Center): ..........................................................................................10

Wheel Linkages and Tandems: ........................................................................................ 11

A-Frame Connection: .......................................................................................................13

Main Pivot Link: ..............................................................................................................15

Self Levelling Completion: ..............................................................................................19

Hitch Assembly: ...............................................................................................................21

Wing Assembly: ...............................................................................................................23

Fold Hinges: .....................................................................................................................24

Wheel and Hub Installation: ............................................................................................25

Wing Cylinder Pins: .........................................................................................................27

Wheel Linkage Adjustments: ...........................................................................................28

Mechanical Adjust Wheel (1.0M Wing): .........................................................................30

Gauge Wheel: ...................................................................................................................31

Connecting Frame Sections: ............................................................................................32

Folding Cylinders: ...........................................................................................................33

Hydraulic Assembly Info: ................................................................................................34

Final Inspection: ...............................................................................................................37

Saftey Decal Installation: .................................................................................................38

Notes: ...............................................................................................................................43