Konica Minolta bizhub C364 User manual

Other Konica Minolta All In One Printer manuals

Konica Minolta

Konica Minolta bizhub C4050i User manual

Konica Minolta

Konica Minolta bizhub 180 User manual

Konica Minolta

Konica Minolta bizhub C554e User manual

Konica Minolta

Konica Minolta bizhub 350 User manual

Konica Minolta

Konica Minolta BIZHUB PRO 920 User manual

Konica Minolta

Konica Minolta accuriopress c6100 Original instructions

Konica Minolta

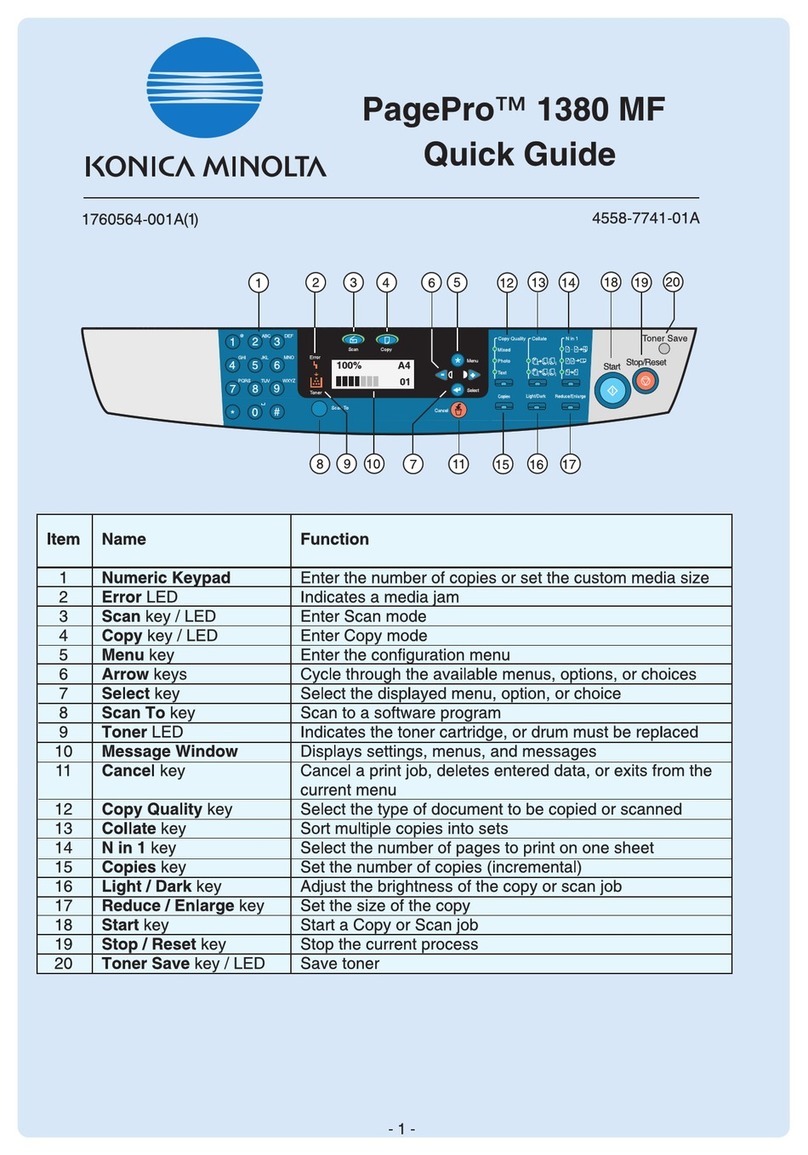

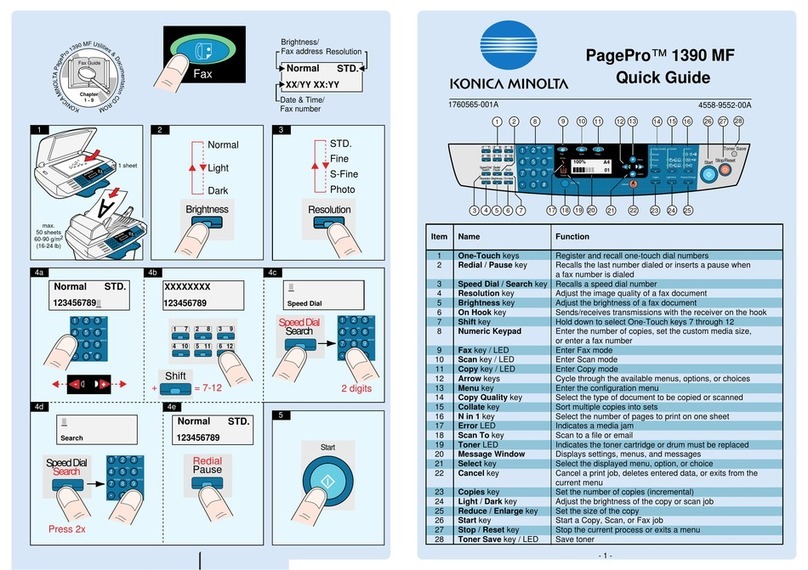

Konica Minolta PagePro 1390 MF User manual

Konica Minolta

Konica Minolta magicolor 8650 User manual

Konica Minolta

Konica Minolta bizhub 423 Supplement

Konica Minolta

Konica Minolta Di2010f User manual

Konica Minolta

Konica Minolta BIZHUB PRO 1050 User manual

Konica Minolta

Konica Minolta bizhub 652 User manual

Konica Minolta

Konica Minolta Bizhub 362 User manual

Konica Minolta

Konica Minolta bizhub C3320i User manual

Konica Minolta

Konica Minolta bizhub 200 User manual

Konica Minolta

Konica Minolta bizhub PRO 1051 Series User manual

Konica Minolta

Konica Minolta Magicolor 1680MF Manual

Konica Minolta

Konica Minolta bizhub 223 User manual

Konica Minolta

Konica Minolta DP-85 User manual

Konica Minolta

Konica Minolta A0FD011 User manual