IMPORTANT SERVICE SAFETY INFORMATION

Operating the receiver outside of its cabinet or with its back removed involves a shock hazard. Work on these

models should only be performed by those who are thoroughly familiar with precautions necessary when working on

high voltage equipment.

Exercise care when servicing this chassis with power applied. if carelessly contacted, can cause serious shock or

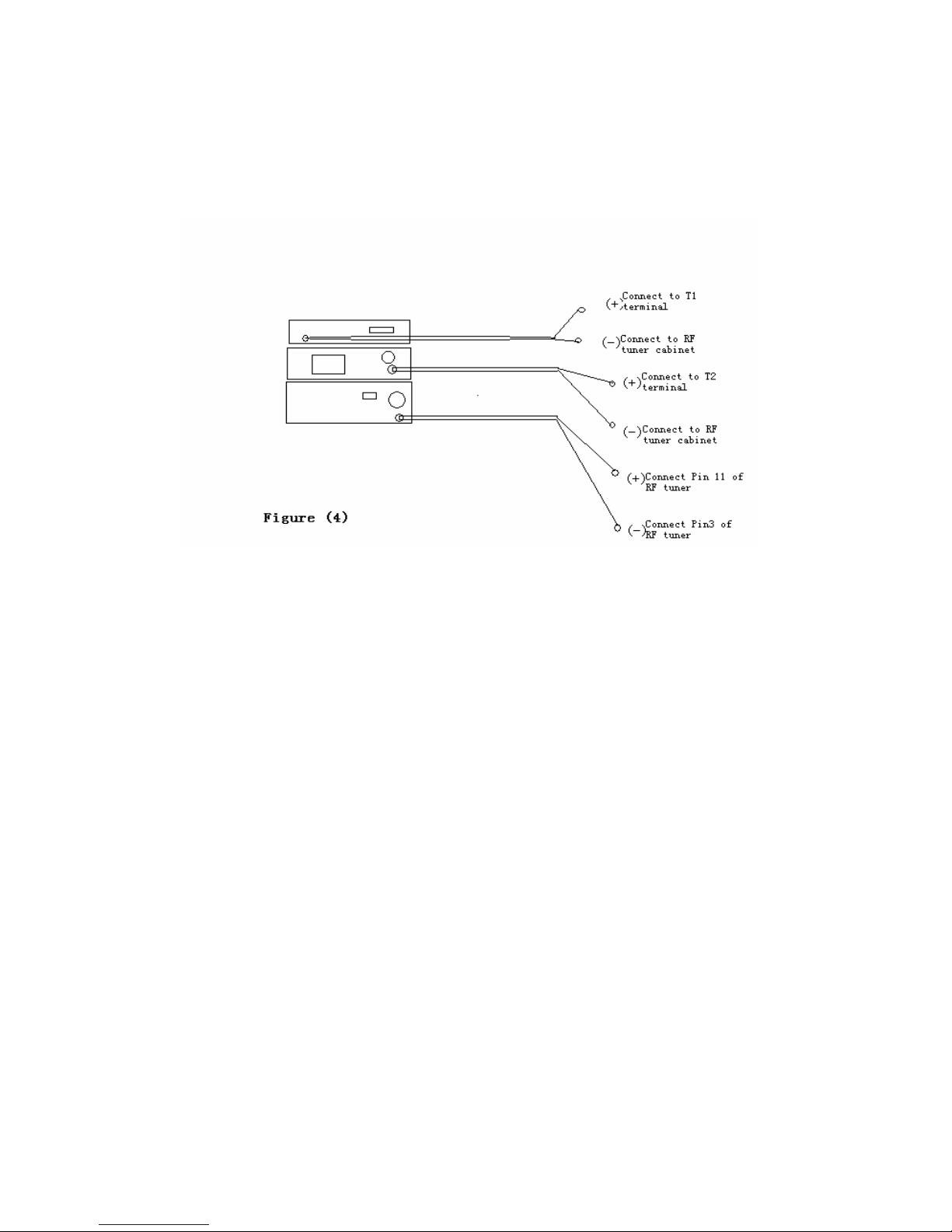

result in damage to the chassis. Maintain interconnecting ground lead connections between chassis, escutcheon, picture

tube dag and tuner when operating chassis.

When it is necessary to make measurements or tests with AC power applied to the receiver chassis, an Isolation

Transformer must be used as a safety precaution and to prevent possible damage to transistors. The Isolation

Transformer should be connected between the TV line cord plug and the AC power outlet.

It is important to maintain specified values of all components and anywhere else in the received that could cause

a rise in operating supply voltages. No changes should be made to the original design of the receiver.

Components shown in the shaded areas on the schematic diagram and/or identified by in the replacement parts

list should be replaced only with exact factory recommended replacement parts. The use of unauthorized substitute

parts man creates may create shock, fire, or other hazards.

Before returning the receiver to the user, perform the following safety checks:

1. Inspect all lead dress to make certain that leads are not pinched or that hardware is not lodged between the chassis

and other metal parts in the receiver.

2. Replace all protective devices such as non-metallic control knobs, insulating fish papers, cabinet backs, adjustment

and compartment covers of shields, isolation resistor-capacitor networks, mechanical insulators etc.

3. To be sure that not shock hazard exists, a check for the presence of leakage current should be made at each exposed

metal part having a return path to the chassis (antenna, cabinet metal, screw heads knobs and/or shafts, escutcheon,

etc.) in the following manner.

Plug the AC line cord directly into a 110V/220V/240V, AC receptacle. (Do not use an Isolation Transformer

during these checks.) All checks must be repeated with the AC line cord plug connection reversed. (If necessary, a

non-polarized adapter plug must be used only for the purpose of completing these checks.)

PLEASE READ BEFORE ATTEMPTING SERVICE

1. Use an Isolation Transformer when performing any service on this chassis.

2. Never disconnect any leads while receiver is in operation.

3. Disconnect all power before attempting any repairs.

4. Do not short any position of the circuit while the power is on.

5. For safety reasons, replace components any with identical replacement parts (SEE PARTS LIST).

6. Before alignment, warm up the TV for at least 30 minutes.

7. When removing a PCB or related component, after unfastening or changing a wire, be sure to put the

wire back in its original position.

8. Inferior silicon grease can damage IC's and transistors. When replacing IC's and transistors, use only

specified silicon grease. Remove all old silicon when applying new silicon.