3

KraftPowercon Sweden AB, Hjalmar Petris väg 49, S-352 46 Växjö, Sweden, Tel: +46 470-705200, Fax: +46 470-705201,

www.kraftpowercon.com

CONTENTS

1 PRESENTATION..................................................................................................6

2 SAFETY INSTRUCTIONS ..................................................................................7

3 TECHNICAL DATA............................................................................................8

3.1 ASSORTMENT ...............................................................................................................................................8

3.2 Electrical data..................................................................................................................................................8

3.2.1 Electrical input data..................................................................................................................................8

3.2.2 Electrical output data ...............................................................................................................................8

3.3 ENVIRONMENTAL DATA ........................................................................................................................9

3.4 MECHANICAL DATA.................................................................................................................................9

3.5 CONFORMITY WITH STANDARDS .......................................................................................................9

4 FUNCTIONAL DESCRIPTION.......................................................................10

4.1 GENERAL......................................................................................................................................................10

4.2 RECTIFIER MODULES...............................................................................................................................10

4.2.1 General ......................................................................................................................................................10

4.2.2 Maneuvering and indications...............................................................................................................10

4.2.3 Voltage control.........................................................................................................................................10

4.2.4 Current control ........................................................................................................................................11

4.2.5 Temperature control...............................................................................................................................11

4.2.6 Output power control ............................................................................................................................11

4.2.7 Fan speed control....................................................................................................................................11

4.2.8 Loadsharing..............................................................................................................................................11

4.2.9 Overvoltage DC (HVSD).......................................................................................................................11

4.2.10 Over-/Undervoltage AC ........................................................................................................................12

4.2.11 External blocking.....................................................................................................................................12

4.2.12 Hot swap...................................................................................................................................................12

4.3 FUNCTIONS OF COMPLETE CHARGING RECTIFIER....................................................................12

4.3.1 General ......................................................................................................................................................12

4.3.2 Float charging ..........................................................................................................................................13

4.3.3 Equalizing charging................................................................................................................................13

4.3.4 Battery circuit test ...................................................................................................................................13

5 OPERATION .......................................................................................................14

5.1 GENERAL......................................................................................................................................................14

5.2 RECTIFIER MODULES...............................................................................................................................14

5.2.1 General ......................................................................................................................................................14

5.2.2 Manoeuvre................................................................................................................................................14

5.2.2.1 ON .........................................................................................................................................................14

5.2.2.2 STBY (standby) ...................................................................................................................................14

5.2.3 Indications ................................................................................................................................................14

5.2.3.1 AC OK ..................................................................................................................................................15

5.2.3.2 DC OK ..................................................................................................................................................15

5.2.3.3 ALARM ................................................................................................................................................15

5.2.3.4 CURRENT............................................................................................................................................15

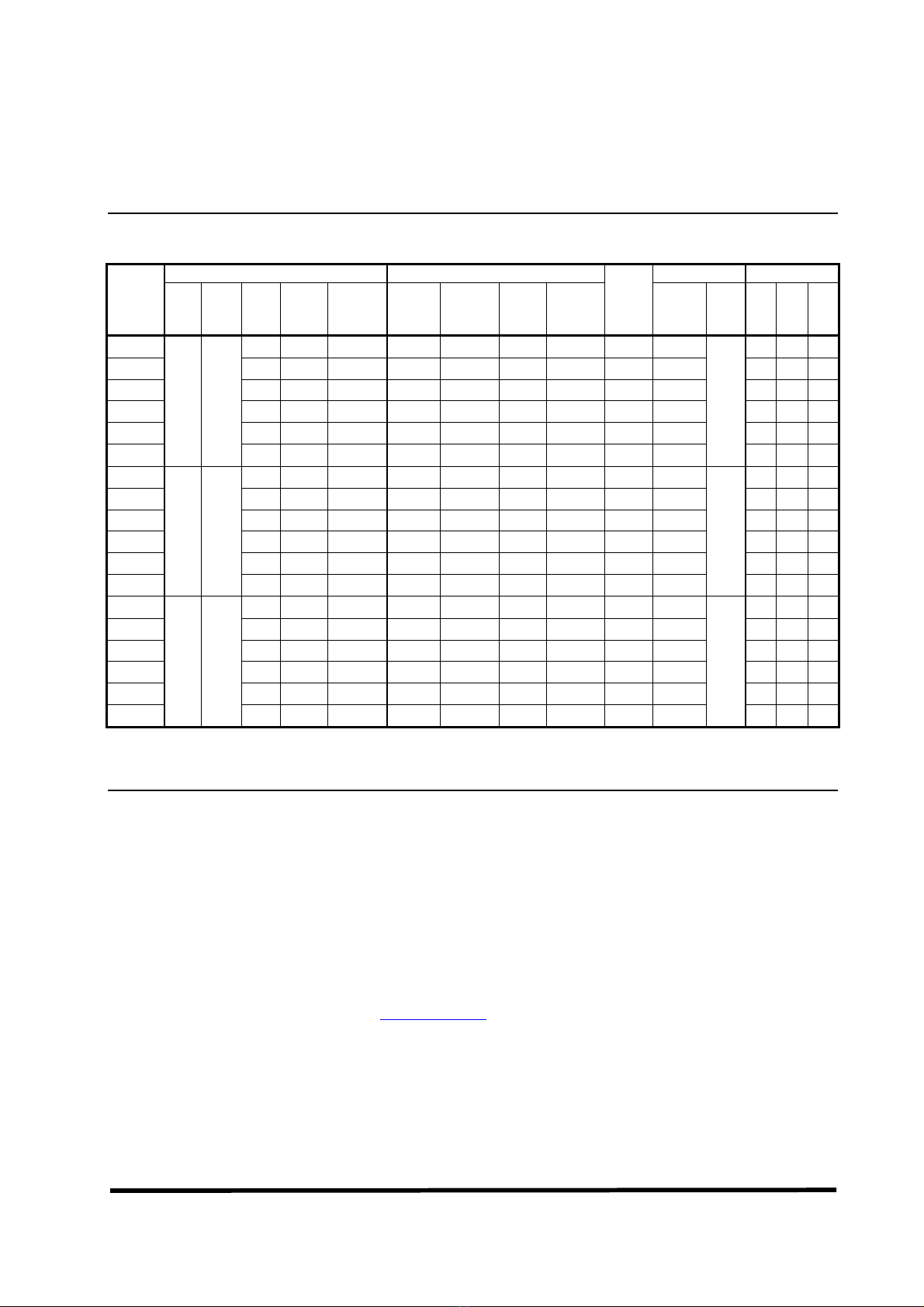

5.2.3.5 <Indication table .................................................................................................................................16

5.3 MONITORING UNIT PCM2.....................................................................................................................16