AutoMeter 5336 User manual

INSTALLATION INSTRUCTIONS

Pit Road Speed Gauge and Tube

2650-1339-00

INTRODUCTION

Thank you for your purchase of the Pit Road Speed device (PRS) from Auto Meter Products, Inc.

The following basic features are included on this product:

• Single precise user-congurable set point • Progressive color change for speed bands

• Quick-reacting, intensely-bright LED light • User selectable dimming function

• Four congurable speed bands • Set point is based on engine RPM

• Quick capture via remote push button

Please read and follow the instructions below regarding the installation and operation of your PRS to receive maximum benet and accuracy from this product.

Failure to follow the information below will void the product warranty and may result in damage to your vehicle, this product, and/or personal injury.

NOTE: This product features INTENSELY-BRIGHT LEDS! This feature is intended for maximum driver visibility during daytime operation and high glare situations.

Usage of this product at full brightness during nighttime or extremely dark settings may adversely affect driver’s vision. Auto Meter strongly recommends that you

familiarize yourself with the dimming function of this product and that you do not operate the product at full brightness during dim or dark lighting conditions.

INSTALLATION

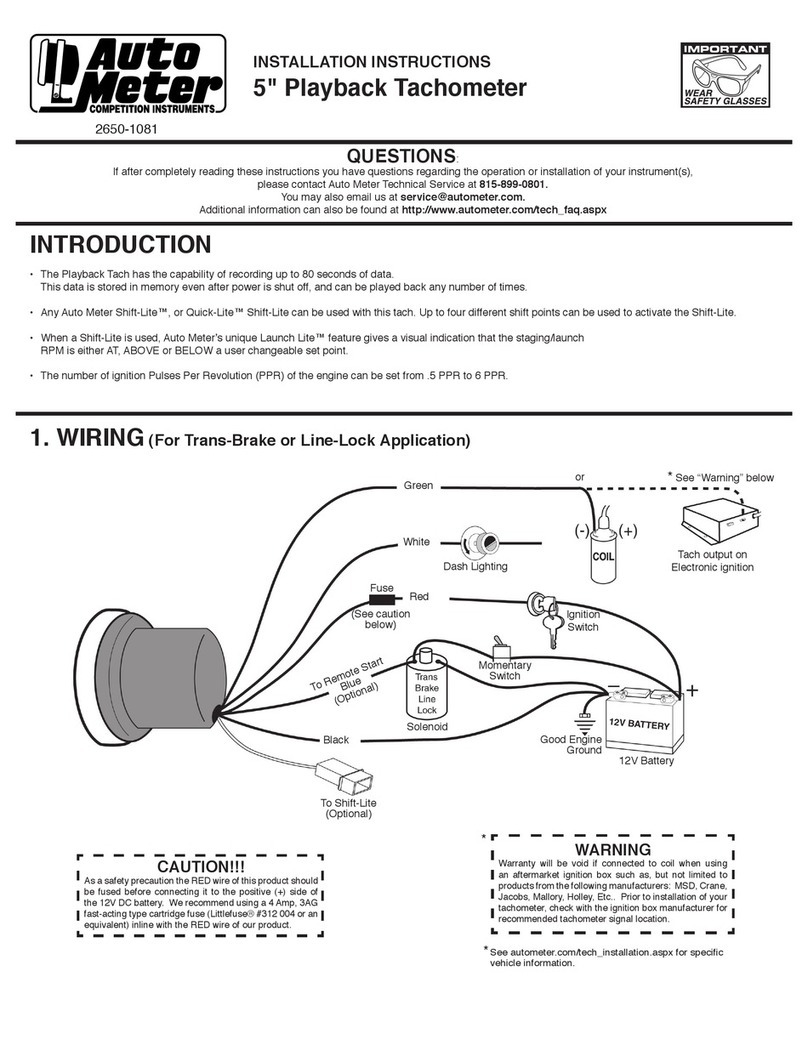

1. Disconnect the negative (-) battery cable.

2. Gauge can be mounted in a 2 1/16” dia. hole with the bracket supplied. Gauge can also be mounted in an Auto Meter Mounting Cup, Panel, or Auto Meter

Gauge Works Pod.

3. Tube version can be mounted on the dash or strapped to the steering column.

4. Wire the PRS as indicated. See schematic on following page for more info:

Red Wire: Connect to a fused and switched 12V positive source that is turned on and off with the ignition switch.

Black Wire: Connect to a good engine, chassis, or battery ground.

Green Wire: Connect to the negative terminal of a standard ignition coil, or to the “Tach Output” terminal on the Electronic Ignition Module. (See diagram)

Blue Wire: (Optional) Connect to a Remote Capture Switch “Normally Open” contact (normally open, momentary closed).

QUICK SET OPTIONS:

Day/Night Dimming control: This product is extremely bright at the maximum setting for best visibility for drivers during high glare situations. Auto Meter

does not recommend operating this product at full brightness during extremely dark or night time driving conditions. To adjust this product from the daytime or

“High” brightness setting to the nighttime or “Low” brightness setting do the following:

• Press the MODE (+) button. The light will illuminate at the new brightness level.

RPM SET POINT QUICK SET - To change your PRS Set Point Setting quickly, use one of the following methods:

1. ENTER Button method:

When the car is in the desired gear and moving at the desired speed, press the ENTER button. You will see the Shift Light turn on Green, indicating

the new setting was captured.

2. Remote Capture Switch method:

This method requires the Blue wire be attached to a “Normally Open” switch (normally open, momentary closed) mounted in a convenient location.

When the car is in the desired gear and moving at the desired speed, press and release switch button. You will see the Shift Light turn on Green,

indicating the new setting was captured. (Note: The RPM is captured the moment the switch is released)

SETUP and OPERATION MODES

A.) RPM BANDS – The PRS will become active when the RPM input signal is within the range of four, user congurable, RPM bands. These bands are

named LO, GO, HI and TOO HI. The width of each band is user congurable, and can be set at any RPM value greater than 10 RPM. The values are factory

preset to the following:

The indicator light will become active when the input RPM falls within the current user congured RPM bands. All bands are relative to the current Set Point

value (see Quick Set Options). The set point will be centered in the GO band. The Indicator light will be active as follows:

For example, using the factory defaults, and a Set Point of 3500 RPM, the Indicator light will work as follows:

A tach calibrator is required to accurately set the RPM bands. To Edit the RPM Bands:

1. Press and hold the EXIT button. The shift light will begin Flashing Yellow.

2. Set the RPM signal to the value that represents the bottom of the LO band (i.e. 2800 rpm).

3. Press and release the ENTER button to capture this value. The shift light will now be a steady Yellow.

4. Set the RPM signal to a value that represents the bottom of the GO band (i.e. 3000 rpm).

5. Press and release the ENTER button to capture this value. The shift light will now be a steady Green.

6. Set the RPM signal to a value that represents the bottom of the HI band (i.e. 3200 rpm).

7. Press and release the ENTER button to capture this value. The shift light will now be a steady RED.

8. Set the RPM signal to a value that represents the bottom of the TOO HI band (i.e. 3300 rpm).

9. Press and release the ENTER button to capture this value. The shift light will now be a Flashing RED.

10. Set the RPM signal to a value that represents the top of the TOO HI band (i.e. 4300 rpm).

11. Press and release the ENTER button to capture this value. The shift light will now be Off.

The Pit Road Speed Light will calculate the RPM Band widths from the captured values, store them in the

EEPROM, and return to normal operation.

VALUE (RPM)

TOO HI Band Width 1000

HI Band Width 100

GO Band Width 200

LO Band Width 200

SET POINT and BAND WIDTHS Engine RPM PRS Displays RPM Band Name Tells Driver

Above 4700 Off

+1000 RPM (+1200 from SP) 3701 to 4700 Flashing Red TOO HI Slow Down

+100 RPM (+200 from SP) 3601 to 3700 Red HI Slow Down

+100 RPM 3500 to 3600 Green GO Correct Speed

PRS Set Point (SP) 3500 Green GO Correct Speed

-100 RPM 3401 to 3500 Green GO Correct Speed

-200 RPM (-300 from SP) 3200 to 3400 Yellow LO Speed Up

Below 3200 Off

RPM Value

Band Name Color Lower Limit Upper Limit

TOO HI Flashing Red HI Upper Limit (HI UpperLimit) + (TOO HI Band Width)

HI Red GO Upper Limit (GO UpperLimit) + (HI Band Width)

GO Green SP - 1/2 (GO Band Width) SP + 1/2 (GO Band Width)

LO Yellow GO (Lower Limit) - (LO Band Width) GO Lower Limit

Note: A RPM value entered must be greater than the previously entered value. If the RPM value is lower than a previously

entered value, nothing will be entered, and the current state of the shift light will be maintained.

B.) LIGHT LEVEL SET – To adjust the high and low brightness settings of your Pit Road Speed Device:

1. Press and hold the MODE (+). The Shift Light will turn on White at the current High brightness level.

2. Use the Menu (+) button to increase the High brightness setting.

3. Use the EXIT (-) button to decrease the High brightness setting.

4. Press the ENTER button. The Shift light will now turn on at the LO brightness level.

5. Use the Menu (+) button to increase the LObrightness setting.

6. Use the EXIT (-) button to decrease the LO brightness setting.

C.) PULSE PER REVOLUTION SET (CYL. CALIBRATION) - Use this feature to calibrate your Pit Road Speed Light to your engine and ignition type. Pulse per

revolution settings refer to the number of pulses or “plug rings” provided by the ignition to the device per engine crank revolution. For example a single coil igni-

tion on a 4-cylinder engine will typically re two cylinders per crank revolution. If your ignition matched this type, you would need to set your PPR value to “2” (See

below).

To set the Pulse Per Revolution:

7. Press and Hold the ENTER button. The shift light will begin ashing in Blue. The number of short ashes will represent the current PPR setting. Two

ashes for 2 PPR, three ashes for 3 PPR, and four ashes for 4 PPR.

8. Use the Menu (+) button to increase the PPR setting.

9. Use the EXIT (-) button to decrease the PPR setting.

10. Use the ENTER button to capture the current PPR setting and return to normal operation.

ENGINE Most 4 cyl. Most 6 cyl. Most 8 cyl.

PPR 2 3 4

The available ignition pulse settings are 2, 3 & 4.

Learn more about custom gauges on our website.

Other AutoMeter Measuring Instrument manuals

AutoMeter

AutoMeter RC-300 User manual

AutoMeter

AutoMeter Spek Pro Installation manual

AutoMeter

AutoMeter BVA-230OZR User manual

AutoMeter

AutoMeter 2650-1081 User manual

AutoMeter

AutoMeter 6858 User manual

AutoMeter

AutoMeter BVA-200EX User manual

AutoMeter

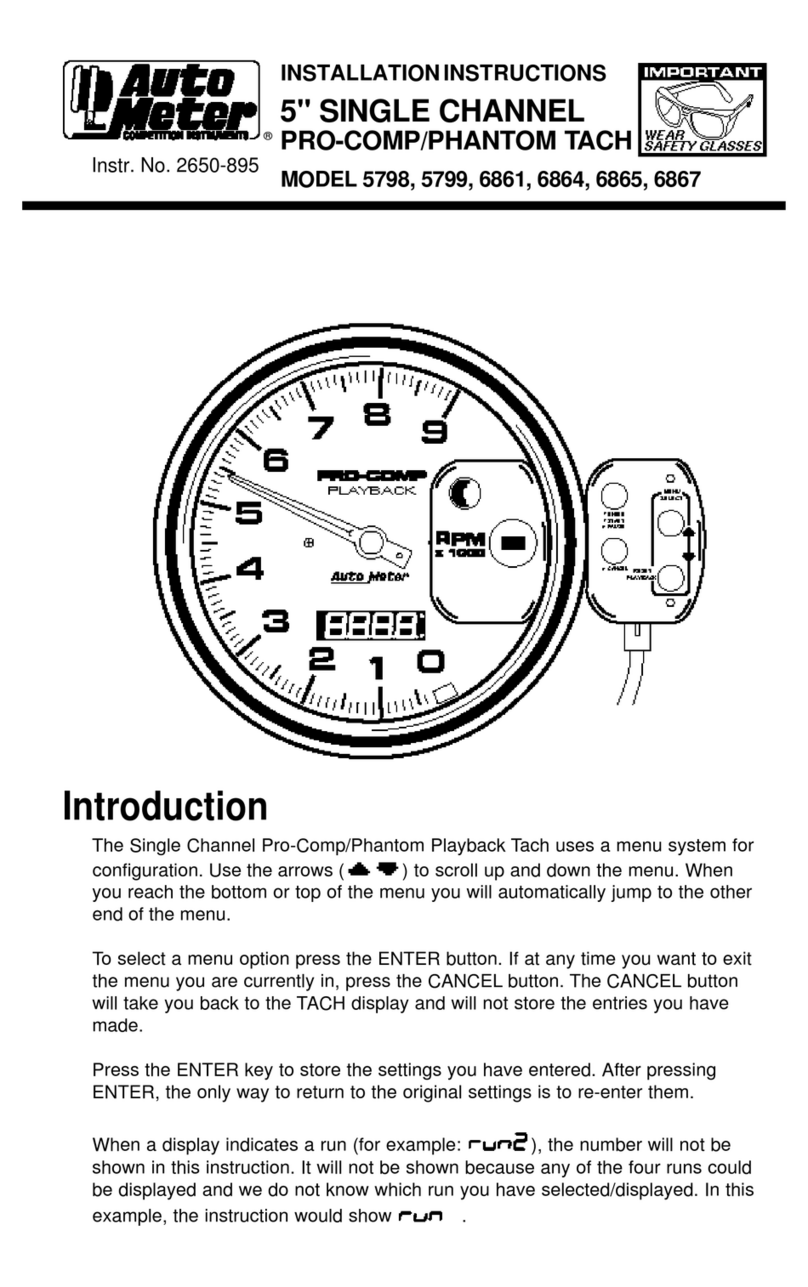

AutoMeter 5798 User manual

AutoMeter

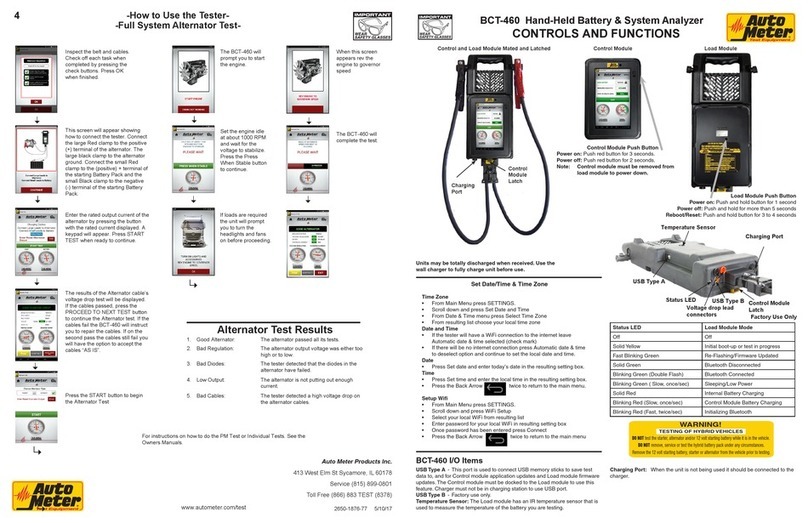

AutoMeter BCT-460 Use and maintenance manual

AutoMeter

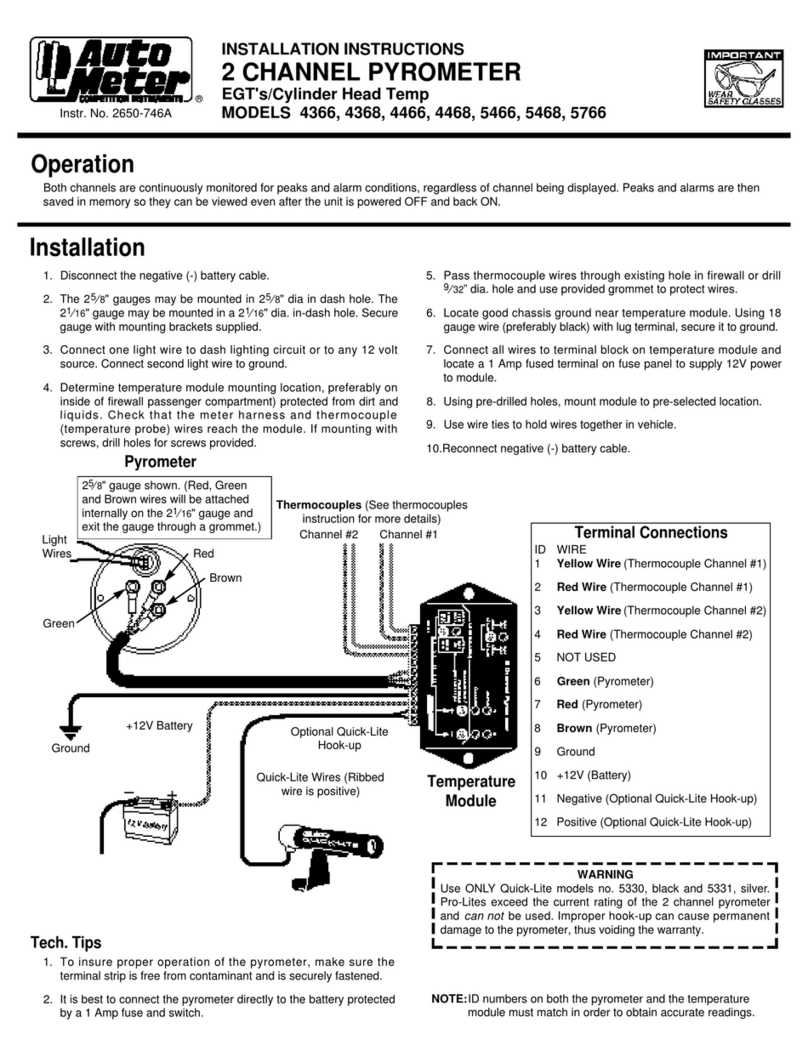

AutoMeter 4366 User manual

AutoMeter

AutoMeter SB-52 User manual