KRIWAN

Industrie-Elektronik

GmbH

·

Allmand

11

·

D-74670

Forc

htenberg · phone (+49) 7947 822 0 · fax (+49) 7947 1288 · e-mail: i[email protected] · home: www.kriwan.comTechnical changes reserved

Product group SEdition: 710.00566.0

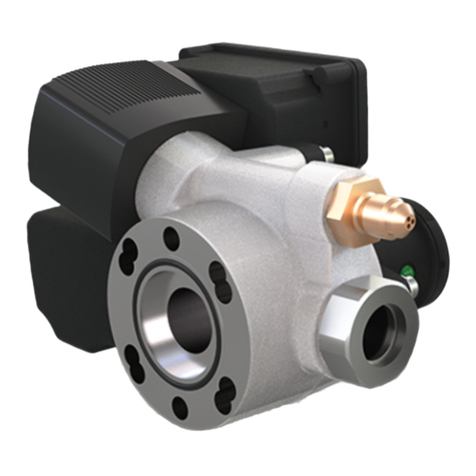

INT280-60

®

INT280-60®

Installation instructions

•

Prior to installation, ensure that the O-ring at the connecting flange is

seated properly.

•

There must be no foreign objects in the oil infeed or outfeed area of

the INT280-60.

•

The device has to be mounted to the compressor horizontally. It can

be rotated by 180°.

•

Use matching washers for the flange fastening screws.

•

Oil level regulator is pre-assembled in installation position.

•

Manually screw in the screws.

•

Afterwards tighten the screws alternating with a torque of 9Nm (M6,

steel 8.8, dry).

•

The electrical connection needs to be carried out according to the

wiring diagram.

•

For use at low temperatures, an oil sump heater has to be installed,

to ensure trouble-free operation of the INT280-60.

•

An oil filter has to be installed in the oil infeed line of the INT280-60,

to prevent the solenoid valve seat from getting dirty.

•

Before the refrigerating system is filled with refrigerant, the system

and the connections of the INT280-60 have to be checked for leaks.

The mounting, maintenance and operation are to be carried out

by an electrician. The valid European and national standards for

connectingelectricalequipmentandcoolinginstallationshaveto

be observed.

Connection lines that extend from the terminal box have to

feature at least a basic insulation.

The user has to ensure that the connections are properly tight.

The electrical connection needs to be carried out according to

the wiring diagram.

Prior to installation, ensure that the pressure in the refrigeration

circuit is and stays equal to the atmospheric pressure.

The voltage supply to the INT280-60 must be switched off prior

to installation/connection and the subsequent tasks.

Flash code

The KRIWAN flash code allows for a quick and easy status display and

troubleshooting.

The flash code consists of a cyclical flash sequence (red / orange or

green/ orange).Thecurrent status can be determined from the number

of pulsing flashes.

Overview flash code

Warning

Error

Flash code

Green lit Oil level OK

Green flashing Oil level too low, fill

Green/Orange flashing Warning, see below for description

Red/Orange flashing Error, compressor is switched off; for

description see table below

1st flashing

sequence

(LED green)

2nd flashing

sequence

(LED orange)

Description

1 2 Oil level monitoring:

Soiled optics, stage 1

2 1 General:

Low supply voltage

2 General:

Unexpected filling behaviour

identified

1st flashing

sequence

(LED red)

2nd flashing

sequence

(LED orange)

Description

1 1 Oil level monitoring:

Oil level too low

2 Oil level monitoring:

Soiled optics, stage 2

3 Oil level monitoring:

Internal sensor fault

2 1 General:

Supply voltage too low

3 General:

Internal alarm

4 General:

External alarm

1.5s

Break 1 green / red

(1-5 pulses) Break 2 orange

(1-5 pulses) Break 1

0.8s 1.5s