intech 21 OPLC-2100 User manual

OPLC-2100 Operation Manual

CONFIDENTIAL

21 Harbor Park Dr. N, Port Washington Phone: 516.656.72211 Fax: 516.626.7201

1

One Pipe Local Controller OPLC2100

1. Introduction

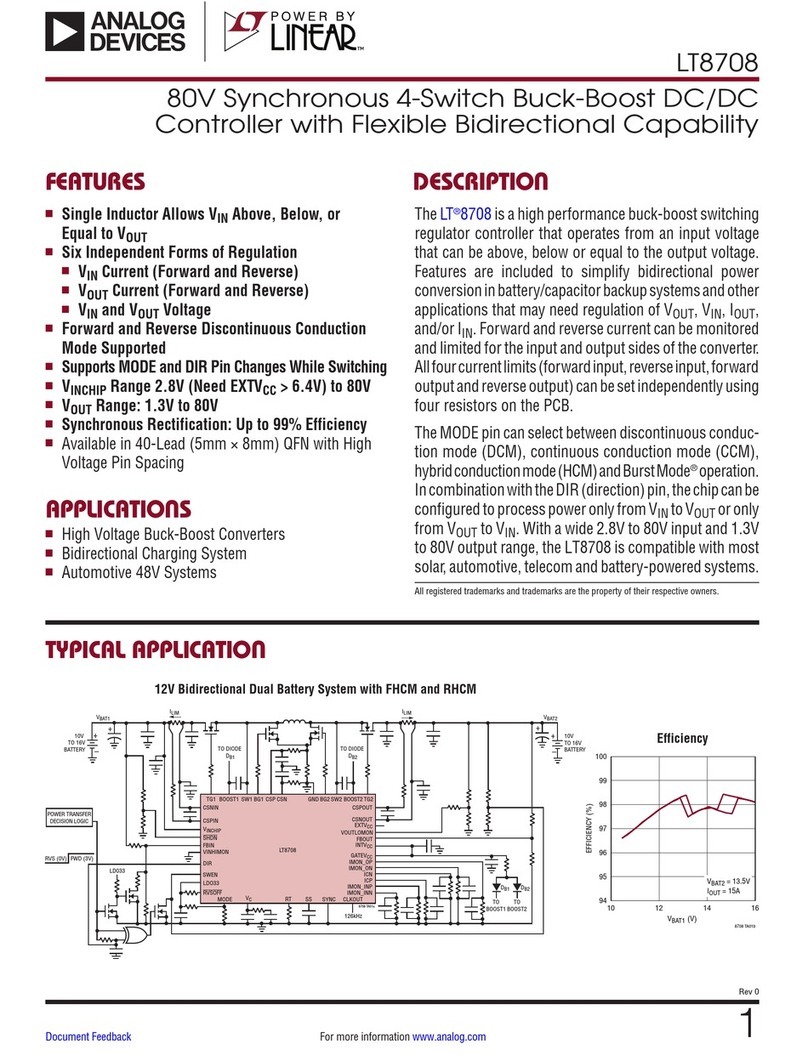

The One Pipe Local Controller OPLC-2100 V3.26 (Fig 1) has been designed to provide control of the Steam Zone Valve in

One Pipe Heating System to regulate the amount of heat (thermal energy) supplied to a building, as well to provide control a

Steam Boiler. On the Steam Boiler application the OPLC-2100 is equipped an auxiliary board to supply 4 –20ma interface

to control the Boiler’s actuator. On this document we will describe the Steam Boiler Control further called as “Boiler+”.

OPLC-2100 works as a standalone controller or can be connected to a Local Server, which furnishes the additional

parameters adjustments to OPLC-2100 based on apartments real time temperature reading in order to improve the heating

supply efficiency and avoid apartment over/under-heating. When the OPLC-2100 is connected to the Local Server it can be

monitored and controlled from the local Intranet and/or Internet with appropriate authentications. On all applications

automatic control of the main parameters in accordance with operation settings and measured temperatures/pressure to

achieve optimal heating delivery and reduce fuel losses.

Figure 1. OPLC2100. Front view

The OPLC-2100 features:

Adjustable Day and Night modes of operation.

Adjustable Winter and Summer modes of operation.

Programmable Heat Up and Cool Down set points.

Morning Boost period up to 120 min.

Provides compensator control for unusual weather conditions

Measures and displays outdoor and heating system sensors temperature.

Measures and displays Boiler’s steam pressure.

Sensors malfunction processing and indicating (open/short situation).

Displays the control cycle parameters and valve status.

Adaptable to different types of standard temperature and pressure sensors, and valve motors.

Simple calibration procedure for the temperature and pressure sensors.

Internal real-time clock/calendar with backup battery.

Automatic storage of setup values. No loss of setup values or mode of operation if power is OFF for extended time.

Automatic Daylight Saving Time clock adjustment.

Locally controlled by the four-button keypad and convenient menu.

Password protection for the critical settings.

Remotely controlled and/or monitored through the RS485 interface.

PID controlled analog output 4-20mA or digital potentiometer for flame modulations to maintain the

required steam pressure during the boiler ON cycle.

OPLC-2100 Operation Manual

CONFIDENTIAL

21 Harbor Park Dr. N, Port Washington Phone: 516.656.72211 Fax: 516.626.7201

2

2. Operation Basics

The OPLC-2100 controller (“Boiler+” version) is designed to provide automatically regulated heat distribution by cycling a

boiler on and off and modulating the flame. The controller continuously calculates the amount of heat requested by the

building taking into account the outdoor temperature, heating system temperature, boiler’s steam pressure and selected

settings. Then the controller assumes that this requested heat value is actually the average heat amount, which must be

delivered to the building. Knowing the CYCLE setting the controller calculates the ‘ON’part of the cycle and controls the

flame modulation. To achieve an optimal performance of the heating system a discrete Proportional-Integral-Derivative

(PID) algorithm is implemented in the “Boiler+” system. Based on generic control loop feedback mechanism the PID

controls flame modulation.

It makes sense to have some constant period of the boiler operation (CYCLE), which, in turn, is divided to ‘ON’ part of

the cycle, during which the boiler is on, and the rest of the cycle, when the boiler is off (‘OFF’ part). In such a scheme of

boiler operation the average amount of heat delivered to a building is proportional to the ratio of’ON’and CYCLE values.

In brief, the controller calculates the heat amount requested by the building (percents) and transforms this value to the

parameters of the boiler cycle (minutes). Main goal of the PID control is supporting stable value of the boiler’s pressure

which is define by pressure set point and three PID parameters. Controller attempts to correct the error between measured

pressure and desired pressure set point by calculating and then outputting corrective action (open or close ) to the boiler’s

Gas Valve actuator. Special sequence of the functionality for the “Boiler+” is implemented to provide proper control of the

boiler during the ‘ON’ part of the Cycle (Fig.3). The flame modulation can starts after the certain period of time called

“Purge” when Gas Valve position achieves special set point (called ‘LFR’ – Low Frame Rate) and after ‘Purge Delay’ set

point. Switch from the ‘ON’ part of the cycle to the ‘OFF’ part of the cycle required “Post Purge” period which includes

time for moving Gas Valve from a point where it was during on the ‘ON’ part to the LFR set point and shat down the boiler.

After ‘Post Purge Delay’ the Valve returns to the zero position. The PID control is active on the Heat Up state and D

(N):Norm state of the Heating Cycle (Fig.3).

3. Controls

The four-button keypad and 16 characters by 2 lines LCD backlit display can be found on the front panel of the

OPLC-2100. These controls provide full local management of the system. Operator can read system status information (e.g.

temperatures, pressure, cycle parameters, and alerts), set the operational modes, and change settings. The control keypad

consists of four pushbuttons: Escape (Esc), Down (), Up (), Enter (Enter). The keys are also marked with letters A, B,

C, D to simplify the passwords memorizing. Holding down the () or () keys will speed up decrement or increment of

setting parameters.

Upper line of the display shows current mode of operation (AUTO, MANUAL, or SET), percentage of heat

requested, and the operational status. Lower line is dedicated to show system status information and setup dialog.

4. Menu

The process of interaction is menu driven. Menu chart is shown on Fig 2. The menu is organized in convenient and

logical way, and follows a simple set of rules.

The menu chart is organized as a set of menu boxes. To navigate between the boxes one should press

Enter key to move to the right on the chart and Esc key to move backward.

Each box contains one or more menu items. To switch between the items inside a box one should press Up

or Down keys.

Each item represents one menu entry: select a setting to change, enter a new setting value, change mode of

operation etc.

If the item contains "NEW" word then the new value has to be entered: Pressing Up and Down keys

change the value. Pressing the Enter key accepts the new value. Esc key rejects the new value, and leaves

the setting unchanged.

If a password is required then one should enter a certain key sequence. For convenience the passwords are

coded as a sequence of letters (e.g. DDBBCBA).

Starting point of the menu is the topmost item of the leftmost box, which is a current cycle parameters line

in the chart. If lost in the menu just press Esc repeatedly, until the display shows something like:

"Cyc:29/61 ON:12”. You are now in the upper left corner of the menu chart.

OPLC-2100 Operation Manual

CONFIDENTIAL

21 Harbor Park Dr. N, Port Washington Phone: 516.656.72211 Fax: 516.626.7201

3

Fig 2. OPLC-2100 Menu Chart

(Boiler+ Configuration)

Cyc:29/61 ON:12

SET OPER MODE

NEW Mode=AUTO

2.8psi FR=17%

NEW Mode=MAN ON

Compensator=+1

NEW Mode=MAN OFF

10:25am Aug10'07

NEW Mode=MAN SET

NEW HeatSet=56%

OD Temp = 42°F

NEW Mode=OFF

SYS Temp=120°F

Enter for more..

SET Compensator

NEW Compens=+1

CACADCB

SetConfiguration

Password1:*******

NewConf-Boiler+

OPLC-2100/644

CACADCB

NewConf-Boiler

VERSION v3.26

SETUP

Password1:*******

SET D:Mild

NEW D:Mild =60

SYSConf-Boiler+

SET N:Mild

NEW N:Mild =25

TotalTm=103hrs

SET N:Stbk

NEW N:Stbk =20

HeatngTm=42hrs

SET Heat Gain

NEW Ht Gain=1.0

D:Mild = 55°F

SET Comp Snstvty

NEW CompSens=1.0

N:Mild = 5°F

SET Boost Span

NEW BoostSpn=0

N:Stbk = 15°F

SET BoostAdvance

NEW Boost Adv=0

D:ICutOff =70°F

SET In D:CutOff

NEW D:CutOff=70°

N:ICutOff =60°F

SET In N:CutOff

NEW N:CutOff=60°

D_Band = 2.5°F

SET D_Band

NEW D_Band= 2.5°F

InDoorTemp=90°F

SET Day Begin

NEW Begin=5:00am

Heat Gain=4.0

SET Day End

NEW End=10:00pm

Comp Snstvty=1.0

SET WntrBegin

NEW WrBeg=Oct.15

Heat Limit=100%

SET WinterEnd

NEW WrEnd=May.15

MotorType=30s

SET Cycle Span

NEW Cycle=60min

BoostSpan=30min

SET Heat Limit

NEW Heat Lim=80%

BoostAdvance=10m

SET Motor Type

NEW MotorTp=30s

Day Begin=5:00am

SET HeatUpStp

NEWHeatUpSP=125

Day End=10:00pm

SET CoolDwnStp

NEWCoolDwnSP=120

WntrBegin=Oct.15

SET HeatUpTm

NEWHeatUpTm=5m

WinterEnd=May.15

SET CoolDwnTm

NEWCoolDwnTm=5m

CycleSpan=30min

SET TIME & DATE

SET Minute

NEW Minute=56

HeatUpSetP=125°F

SET Hour

NEW Hour=2PM

HeatUpTime=5m

SET Month

NEW Month=12

CoolDwnTime=5m

SET Date

NEW Date=5

CoolDwnSetP=120°F

SET Year

NEW Year=2

PID_P = 1.0

OPLC-2100 Operation Manual

CONFIDENTIAL

21 Harbor Park Dr. N, Port Washington Phone: 516.656.72211 Fax: 516.626.7201

4

PID_I = 0.7

DDBBCBA

PID_D = 0.0

SET CALIBRATE

Password2:*******

CAL OUTDoorTemp

NEW ODTAdj=0.

IntSumErr=-7.1

CAL SYStemTemp

NEW SYSTAdj=0

Correction=-6.6

SET Com.ID

NEW Com.ID=3

SetPSenser@4ma

NEWPSes@4ma=

FiringRate=64.3%

SetPSenser@20ma

NEWPSes@20ma=

LowFlameRate=15%

MAINTENANCE

Password1:*******

SET PID_P

NEW PID_P= 0.7

CAL PRESSURE

NEW PRAdj=0.1

PressurStp=5.2psi

=3.0psi

CACADCB

SET PID_I

NEW PID_I=0.5

CAL ValveCloseP

NEW Cadj=572

SampleRate=12sec

SET PID_D

NEW PID_D=0.2

PurgeDelay=30sec

SET PurgeDelay

NEW PurgeD=30sec

PsPurgeDly=15sec

SET PsPurgeDly

NEW PPurgeD=20sec

PSen@4ma =-15psi

SET Pressure Stp

New Pres=5.6psi

PSen@20ma = 15psi

SET LowFlame LVL

NewFlameLvl=15%

Pressure=4.9psi

SET SamplingRate

NewSampleR=12sec

SYS Temp=120°F

OD Temp = 42°F

Com.ID=1

Fig.3 Typical track of the Fuel Valve position for a regular Heating Cycle.

(‘OFF’ part of the Cycle is not shown)

| Purge state | HeatUp | D:Norm state | PPrg (Post Purge) state

| | state | ~ ~~ ~~ | |

Valve Position -------|--------- |~ ~ ~ ~~ ~ ~~~ ~~~~~~~~~~~~~---------------------------|

When the Pressure | | ~ | |

Set-Point is reached | ~ | ~ | |

| | ~ | | |

| | ~ | | |

| | ~ | | |

| LFR ________________~ | | _______________LFR |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

|-----|---------------|----------|---------------------------------|----- |--------------|-----|

| Ramp| Purge Delay | | |Slope1|PostPurgeDelay|Slope2

*Boiler *Boiler

’ON' 'OFF'

OPLC-2100 Operation Manual

CONFIDENTIAL

21 Harbor Park Dr. N, Port Washington Phone: 516.656.72211 Fax: 516.626.7201

5

LFR–Low Flame Rate. Sign ‘~’ shows that PID control of the Gas Valve movement is altering.

5. Operational States and System Information

5.1. Upper Line of the Display

The OPLC has five Modes of Operation: AUTO, SET, MANUAL ON, MANUAL OFF and OFF.

The Mode can be selected by operator or remotely. Depending on the Operation Mode and many parameters the controller can be in one of the Operational

States. The Mode and the Operational State are permanently displayed in the upper line of the LCD as follows:

LCD Indicator

Mode of

Operation

Upper line

begins with

Description

Possible Operational States

(indicate on the right corner of the upper line)

OFF

OFF:

PPrg (Post Purge)

Auto

AUTO: hh%

AUTO^max%

Calculated Target Heat Amount to be

delivered, ‘hh’ in the range of (0%-100%)

Summer, D:Mild, N:Mild, D:ICOFF, N:ICOFF, N:Stbk, D:Norm,

N:Norm, HeatUp, CoolDn, Boost and FailSf Purge, PPrg

Manual Set

SET:hh%

Target Heat Amount to be delivered,

Purge, PPrg

MAN ON

MANUAL ON:

Sets Gas Valve to selected position

Purge,PPrg

MAN OFF

MANUAL OFF:

Unconditional shutting down the Boiler.

PPrg

.

Notes: hh –Target Heat Amount (‘hh’ in the range of 0%-100%);

^max –Heat Amount is limited by Heat Limit Set Point.

OPLC-2100 Operation Manual

CONFIDENTIAL

21 Harbor Park Dr. N, Port Washington Phone: 516.656.72211 Fax: 516.626.7201

6

5.2. Operational States and Bottom Line of the Display

Upper Line of LCD

Bottom line of LCD

Description:

Operational

Mode

Operational State

OFF

PPrg (Post Purge)

aa.a ps FR=yy.y%

When mode is changed to ‘OFF’ operation Gas Valve moves to Close position. Where:

aa.a ps –boiler’s pressure (in psi), FR (Firing Rate) - current Gas Valve position (in

percents)

ttsec LFR=zz.z%

When FR == LFR set point then Boiler shats down. Gas Valve will stay on LFR position

until -Post Purge Time Delay (ttsec) expired.

aa.b ps FR=0.0%

After Post Purge Delay the valve is start moving to 0.0% position. aa.b ps - pressure

AUTO:xx%

AUTO:0%

AUTO:100%

D:Norm, N:Norm,

N:Stbk,

Cyc:A/B ON:C

or

Cyc:A/B OFF:D

variants:

1.Cyc:0/CL OFF^CL

2.Cyc:CL/0 ON^CL

Regular Cycle. CL (Cycle Length) is A + B. in minutes.

A = Calculated time amount the boiler must be ‘On’; B = CL –A;

C = Current minutes boiler is ‘On’ or D = = Current minutes boiler is ‘Off’

0% heat to be delivered , Boiler is OFF more then CL minutes;

100% heat to be delivered, Boiler is ON more then CL minutes;

(sine’^’= shows that the boiler stays on ‘On’ or ‘Off’ more time then Cycle length)

AUTO:0%

D:Mild, N:Mild,

D:ICOFF,N:ICOFF

Cyc:0/CL OFF:D,

Cyc:0/CL OFF^CL

Mild Weather or InDoor CutOff.

0% heat to be delivered, Boiler is OFF D minutes (D < CL);

0% heat to be delivered, Boiler is OFF more then CL minutes;

AUTO:100%

Boost

Span=BSm ON:BT

Morning Boost. BS = Boost Span. BT = Current minutes boiler is ‘On’.

AUTO:xx%

Purge

aa.a ps FR=yy.y%

ttsec LFR= zz.z%

Boiler is On. Gas Valve moves toward to LFR. When FR riches LFR, then starts Purge

Delay down counter (ttsec). Purge is finish when ttsec == 0.

AUTO:xx%

PPrg

aa.a ps LFR=yy.y%

ttsec LFR=zz.z%

aa.b ps FR=0.0%

See PPrg on the ‘OFF’ operation description

OPLC-2100 Operation Manual

CONFIDENTIAL

21 Harbor Park Dr. N, Port Washington Phone: 516.656.72211 Fax: 516.626.7201

7

AUTO:xx%

HeatUp

ExtCycle ON:E

Appear after Purge state if SYSTemp < HeatUpSP. Controller will be on HeatUp state

either SYSTemp > HeatUpSP or HeatUpTime is expired.

E = Current minutes boiler is ‘On’.

AUTO:xx%

CoolDn

ExtCycle OFF:E

Appear after ‘OFF’ part of Cycle (on D/N:Norm state) if SYSTemp > CoolDwnSP.

Controller will be on CoolDn state either SYSTemp < CoolDwnSP or CoolDwnTime is

expired. E = Current minutes boiler is ‘Off’.

AUTO:50%

FailSf

Cyc:F/F ON:G

Cyc:F/F OFF:E

Fail Safe - Out Door Temperature Sensor fail, the controller sets 50% heating Cycle.

F = CL/2; G = Current minutes boiler is ‘On’ or E = Current minutes boiler is ‘Off’.

AUTO:0%

Summer

No Modulation

No-heating season

M_Set:xx%

Purge

aa.a ps FR=yy.y%

ttsec LFR = zz.z%

Same as for the AUTO mode of operation (see Purge description above)

PPrg

aa.a ps LFR=yy.y%

ttsec LFR=zz.z%

aa.b ps FR=0.0%

See PPrg on the ‘OFF’ operation description

Cyc:A/B ON:E

or

Cyc:A/B OFF:H

Regular Cycle. Same as for the AUTO mode of operation.

Manual OFF

PPrg

aa.a ps LFR=yy.y%

ttsec LFR=zz.z%

aa.b ps FR=0.0%

(see Post Purge description above)

Manual ON

Purge

aa.a ps FR=yy.y%

ttsec LFR=xx.x%

(see Purge description above)

SET Firing Rate

Option: Press ‘Enter’ at any time and ‘Down’ key (or ‘UP’ key several times in Manual

ON only). (f1M_ON ==1)

aa.apsi SFR=nn.n%

Press ‘Enter’

(f1M_ON ==1)&&(fM_OnPruf ==1)

aa.apsi SFR=mm.m%

Press ‘Up’ or ‘Down’ Key

bb.cpsi FR=yy.y%

Press ‘Enter’ or ‘Esc’ to quit from the option

Press ‘Up’ or ‘Down’ Key To display other information’s (scroll information).

1. Option –possibility to change Firing Rate on +/- 0.8% by pressing ‘Up’ or ‘Down’ key;

(SFR –Set Firing Rate (increment/decrement) current Gas Valve position.)

(FailSf )

OPLC-2100 Operation Manual

CONFIDENTIAL

21 Harbor Park Dr. N, Port Washington Phone: 516.656.72211 Fax: 516.626.7201

9

5.3 System Status Information

All operational parameters and useful information can be seen on the low line of the LCD display by using

Up/Down and Enter keys (see Fig.2 left corner). The following information can be selected (by pressing Up or Down key)

for displaying on the lower line of the LCD:

Status Information

Example

Description

Heating Cycle Parameters

Cyc:19/41 ON:12

The number before slash: ‘ON’ part of the cycle, minutes. The number after

slash: ‘OFF’ part of cycle period, minutes. The number after ON: current

time of the ‘ON’/’OFF’ part of the cycle, minutes. (The cycle length is

60minutes).

Pressure and Firing Rate

4.2ps FR=17.8%

The pressure is represented in psi. The Firing Rate (FR) is percent of the

Gas Valve opening.

Compensator

Compensator=+1

Indicates the COMPENSATOR setting.

Time and Date

10:25am Sep10'08

Current time and date. The "am/pm" displayed with capital letters when

Daylight Saving Time is in effect.

Outdoor Temperature

OD Temp=52°F

Temperature at the RTD outdoor sensor (="fail" if temperature sensor

malfunction).

System Temperature

SYS Temp =120°F

Temperature at the RTD sensor installed on the pipe segment farthest piping

distance from the boiler and above the water line of the boiler.

(="fail" if temperature sensor malfunction).

More information

Enter for more…

Pressing the ‘Enter’ key will show additional information (see Fig.2 left

corner).

Dependent of the Operational Mode and Operational State contents of two first rows of the Table can be change and will

appear us follows:

OPLC-2100 Operation Manual

CONFIDENTIAL

21 Harbor Park Dr. N, Port Washington Phone: 516.656.72211 Fax: 516.626.7201

10

6. Mode of Operation

The upper line of the display shows the current mode of operation (AUTO, SET, MANUAL ON, MANUAL OFF, and

OFF), indicates amount of heat (thermal energy) to be supplied during AUTO or SET operation. The right corner of the

upper line indicates the current Operational State. (Please refer to the detailed description on section 10).

The OPLC-2100 operates in one of the following modes:

Operation

Mode

Description

AUTO

The controller provides automatically regulated heat distribution by cycling a boiler on and off and

modulating the flame cycling in accordance with the measured temperatures, time of day, and selected

settings. This mode is designed to be the main mode of operation. If the system settings are set

properly, then there is no need in manual intervention in the system performance virtually at any

weather condition.

In AUTO mode the controller distinguishes three periods of day:

1. Morning Boost period begins at 5:00AM. The Morning Boost setting defines the boost duration.

During the Boost period the Boiler will deliver maximum amount of the thermal energy. (By using

‘Boost Advance’ set point operator can shift start of the Boost period for early time)

2. Daytime period (from boost period end to 10PM). Normal daytime operation.

3. Nighttime period (10PM to 5AM). The amount of delivered heat can be reduced against the daytime

period, as defined by the COLD NIGHT and NIGHT SETBACK settings.

Note:

If Out Door Temperature has been reached Day Mild or Cold Night Set Point the Boiler will be shut

down via special procedure named “Post Purge” (which is will be indicated on the right corner of the

upper line of the LCD as ‘PPrg’ operational state). ‘D:Mild’or ‘N:Mild’operational state will be

displayed (for DAY/NIGHT mild weather) after Post Purge procedure has finished. In the summer

season and InDoor CutOff the Boiler will be shut down in the same way and operational state will be

indicate as ‘Summer’ or ‘D:ICOFF’(‘N:ICOFF’) accordingly. On this situation any heating process

can be controlled by entering SET, MANUAL ON, MANUAL OFF, and OFF operations.

(For the detailed description of the Operational states, please refer to section 10).

SET

The amount of delivered heat is set manually to the desired value (0 to 100%). The heating cycle is

fixed and doesn’t change. This mode can be useful at some circumstances (e.g. if the temperature

sensor failed and automatic control is impossible)

MAN ON

This operation allows setting the Gas Valve to selected position or manually modulating the flame.

Can be used on emergency or adjustment period.

MAN OFF

Unconditional shutting down the Boiler by meaning of the Post Purge procedure. This mode can be

used in emergency if one wants to shut down the boiler.

OFF

One should select SET OPER MODE item in the menu to change the mode, press Enter, then, with Up or Down key select

a new mode, and press Enter. When the SET mode is selected, the new heat amount percentage must be entered. During the

Post Purge procedure (‘PPrg’ operational state) new operation can not be entered.

OPLC-2100 Operation Manual

CONFIDENTIAL

21 Harbor Park Dr. N, Port Washington Phone: 516.656.72211 Fax: 516.626.7201

11

Fig 4. Heat Request vs. Outdoor Temperature curves.

(Mild Weather=55, Compensator=0)

Fig 5. Heat Request vs. Outdoor Temperature curves.

(Mild Weather=55, Heat Gain=3.0, Compensator Sensitivity=3.0)

OPLC-2100 Operation Manual

CONFIDENTIAL

21 Harbor Park Dr. N, Port Washington Phone: 516.656.72211 Fax: 516.626.7201

12

7. Compensator

The COMPENSATOR setting provides manual adjustment to the amount of heat being delivered to compensate the

influence of some weather conditions (e.g. strong wind).

The controller, when calculating the amount of requested heat, subtracts the Compensator value from the outdoor

temperature multiplied by the Compensator Sensitivity thus correcting the value of requested heat.

The COMPENSATOR range: -5 to +5 units. Positive values of the setting increase heat delivery, while negative

values reduce it. Default value is 0.Fig.5 illustrates the Compensator's influence on the control curve.

This is the only setting, which is not protected by the password

8. Operation Settings

To provide correct and reliable operation of the OPLC-2100 the operational parameters must be set properly. The

parameter section of the menu is divided in two parts (SETUP and MAINTENANCE ). Each part protected with a

password. Use following tables as guidelines when selecting parameters' values:

SETUP (password: CACADCB)

Setting

Description

D:Mild (DAY

MILD WEATHER)

The controller issues heat request of 0% when the outdoor temperature is higher than this set

point. Range: 40° to 80 °F with 1° step. Default value is 55°F.

N: Mild (NIGHT

MILD WEATHER)

If the outdoor temperature is lower than this setpoint and the time is between 10PM and 5AM,

then the heat request value is corrected in accordance with the NIGHT SETBACK setting.

If the outdoor temperature is higher than this setpoint and the time is between 10PM and 5AM,

then the heat request is set to 0%.

Range: 20° to 60 °F with 1° step. Default value is 40°F.

N:Setbk (NIGHT

SETBACK)

The controller adds to the outdoor temperature the NIGHT SETBACK value thus correcting the

heat request value to reduce heat delivery during the nighttime.

Range: 0° to 80 °F with 1° step. Default value is 10°F.

Heat Gain

Determines the slope of the control curve: Heat Request vs. Outdoor Temperature.

Fig 3 represents the family of control curves with Heat Gain as parameter when

COMPENSATOR=0 and NIGHT SETBACK=0.

Positive Compensator values shift a curve up, negative - down.

Positive Night Setback values shift a curve down.

Range: 1.0 to 50.0 with 0.1 step. Default value is 1.0

Comp Snstvty

Determines the weight of the compensator's unit.

Range: 0.1 to 9.9 °F/unit with 0.1 step. Default value is 1.0

Boost Span

Morning boost time span. The controller boosts heat only with AUTO mode in effect.

Range: 0, 30, 60, 90 or 120 minutes (0 means no boost) Default value is 0.

BoostAdvance

This parameter determines early (before 5:00am) boost time. Default value is 0.

OPLC-2100 Operation Manual

CONFIDENTIAL

21 Harbor Park Dr. N, Port Washington Phone: 516.656.72211 Fax: 516.626.7201

13

In D:CutOff

(In Door Day

Temperature

Cutoff)

The controller closes the valve completely when the In Door temperature average (supplied from

host computer) is higher than this set point during the Day - time between Day Begin and Day

End (D:ICOFF state). Range: 40 to 90 °F

In N:CutOff

(In Door Night

Temperature

Cutoff)

If the In Door temperature average (supplied from host computer) is higher than this set point

and the time is between Day End and Day Begin, then the valve will be closed completely

(N:ICOFF state). Range: 40 to 80 °F

D_Band

Used along with ‘In Door Temperature’ parameter and ‘In Door Day/Night Temperature Cutoff’ Set

Point. This parameter defines the allowable delta between the actual In Door Temperature and

Cutoff Set Point.

Range: 0.1°F to 19.9°F with 0.1°F steps

Day Begin

Hours and minutes (with 10 minutes step) when Day Begins

Day End

Hours and minutes (with 10 minutes step) when Day Ends

WinterBegin

Month and Day when Winter Begin (dependent of the region)

WinterEnd

Month and Day when Winter End (dependent of the region)

Cycle Span

Heating cycle period, minutes.

Range: 20 to 90 minutes, Step 10minutes. Default value is 60 minutes

Heat Limit

This parameter overrides the system calculated ‘ON’ period if ‘ON’ bigger than ‘Hit Limit’

Default value is 100%.

Motor Type

Motorized valve nominal timing (in seconds) for 90° or 160° stroke.

Range:{15,30,45,60,72,90,144,180,240}seconds. Default = 30seconds.

HeatUpStp

New cycle will comment when the system temperature on the Cold Pipe Temperature Sensor

reaches this set point (please see diagram on Figures 5-7, red line).

Range: 40 to 240°F, Step 1°F Default value is 125°F

CoolDwnStp

Heating can start if the system temperature drops below this set point (checks each time after

current cycle finished). (please see diagram on Figures 5-7, blow line).

Range: 40 to 240°F, Step 1°F Default value is 120°F

HeatUpTm

Controller can start new cycle either SYSTemp > HeatUpSP or HeatUpTm is expired.

Range: 0 to 90 minutes, Step 1minute. Default value is 5minutes.

CoolDwnTm

Heating can start either SYSTemp < CoolDwnStp or CoolDwnTm is expired.

Range: 0 to 90 minutes, Step 1minute. Default value is 5minutes.

TIME & DATE

The submenus of this setting allow setting up the internal real time clock of the controller. It is

essential to have the clock set properly, because the Boost, Night Saving modes and Daylight

Saving Time Adjust rely on the clocks accurate setting.

CALIBRATE

Submenu for Calibration of Temperature and Pressure Sensors. Uses to calibrate a current for

motorized valve. (Please see chapter #10)

Com.ID

Each OPLC-2100 connected to the local server via the RS485 bus. To establish proper connection

the controller should have a unique communication address (ID).

Range: 1 to 99.

OPLC-2100 Operation Manual

CONFIDENTIAL

21 Harbor Park Dr. N, Port Washington Phone: 516.656.72211 Fax: 516.626.7201

14

‘MAINTENANCE’menu contains data to control the Motorized Gas Valve by meaning of boiler’s pressure and PID

algorithm .

MAINTENANCE (password: CACADCB)

Setting

Description

PID_P

‘P’ coefficient for PID algorithm. Range: 0 to 99.9. Default = 5. Step 0.1.

PID_I

‘I’ coefficient for PID algorithm. Range: 0 to 99.9. Default = 1 .Step 0.1.

PID_D

‘D’ coefficient for PID algorithm. Range: 0 to 99.9. Default = 0. Step 0.1.

PurgeDelay

Purge Delay (please see Fig.) Range: 0 to 255 sec. Default = 30 sec. Step 1sec.

PsPurgeDly

Post Purge Delay (please see Fig.) Range: 0 to 255 sec. Default = 15 sec. Step 1sec.

Pressure Stp

Maximum boiler’s pressure set point. Range 0 to 35 psi. Default = 2psi. Step 0.1psi

LowFlameRate

Starting point before Flame modulation. can start and Heating Cycle can complete. Range 0% to 100%.

Default = 15%. Step 1%.

SamplingRate

PID algorithm sampling rate. Range 1 t0 255 sec. Default = 12 sec. Step 1sec.

9. High Pressure Processing

There are three operational modes the controller can react on the High Pressure: ‘AUTO’, ‘MAN SET’, and ‘MAN ON’.

In the ‘AUTO’ and ‘MAN SET’ mode of operations the controller will finish current operational Cycle and will not start the

next until (PRESSURE + 2) <= PRESSURE_SP (0.2 psi hysteresis).

In the ‘MAN ON’ mode the controller will close the fuel valve to 0%.If the boiler was turned OFF before changing the

operational mode to” MAN ON” it wouldn’t turn the boiler ON until the pressure become less than the Set-Point minus

.2psi

High Pressure Indication on the LCD

f6HighPressure==1

AUTO

MAN SET

MAN ON

Top Line

AUTO:75% D:Norm

SET:25%

MANUAL ON:

Bottom Line

Cyc:45/15 OFF-hP

Cyc:15/45 OFF-hP

aa.a ps OFF-hP

f2PressureFail==1

Top Line

AUTO:75% D:Norm

SET:25%

MANUAL ON:

Bottom Line

Cyc:45/15 PS_Fail

Cyc:15/45 PS_Fail

PS_Fail OFF

10. Calibration Procedures

The temperature sensor, pressure sensor, and motor current loop interface must be calibrated after the initial system

installations or after the parts replacement. The OPLC-2100 facilitates the calibration procedure. To enter the calibration

section of the menu, select SET CALIBRATE and then enter password. Following table provides explanations for the

calibration procedure.

1. Select CAL OutDoorTemp. and press Enter

2. The upper line of the display indicates mode of operation (“CAL”) and

OPLC-2100 Operation Manual

CONFIDENTIAL

21 Harbor Park Dr. N, Port Washington Phone: 516.656.72211 Fax: 516.626.7201

15

Outdoor Temperature

Sensor Calibration

shows actual reading of the temperature sensor: " ODT=xx.y° ".

3. The lower line of the display shows possible adjustment for example

“NewODTAdj=0.1°”

4. Press Up or Down key to make the ODTemp equal to the real outdoor

temperature, measured by the reference thermometer.

5. Press Enter.

System Temperature

Sensor Calibration

1. Select CAL SystemTemp. and press Enter

2. The upper line of the display indicates mode of operation (“CAL”) and

shows actual reading of the temperature sensor: " SYST=xx.y° ".

3. The lower line of the display shows possible adjustment for example

“NewSYSTAdj=0.1°”

4. Press Up or Down key to make the SYST equal to the real system

temperature, measured by the reference thermometer.

5. Press Enter.

Set Pressure Sensor Value

for minimum current (4ma)

1. From Calibration Menu Select SetPSensor@4ma and press Enter

2. The upper line of the display indicates mode of operation (“CAL”)

3. The lower line of the display shows possible adjustment for example

“NewPSns@4ma=-15psi”

4. Press Up or Down key to make desired value, then press Enter.

Set Pressure Sensor Value

for maximum current (20ma)

1. From Calibration Menu Select SetPSensor@20ma and press Enter

2. The upper line of the display indicates mode of operation (“CAL”)

3. The lower line of the display shows possible adjustment for

example “NewPSns@4ma=15psi”

4. Press Up or Down key to make desired value, then press Enter

Pressure Sensor Calibration

1. Select CAL PRESSURE. and press Enter

2. The upper line of the display indicates mode of operation (“CAL”) and

shows actual reading of the pressure sensor: " PRS=xx.y psi ".

3. The lower line of the display shows possible adjustment for example

“New PRSAdj=0.1°”

4. Press Up or Down key to make the PRS equal to the real boiler pressure,

measured by the reference pressure transducer.

5. Press Enter.

Motor current loop interface

Calibration

From ‘MANUAL CLOSE’ Operation when Valve is closed (VALVE POS=0%):

1. Connect ampere meter between the ZVLC’s terminal pin#2 (CLOSE) and

motor connector (in case of absent the motor , 100oHm resistor can be

used).

2. Select CAL ValveClosePs. and press Enter

3. The upper line of the display indicates mode of operation (“CALBR”) and

ClsPsCr=4ma.

4. The lower line of the display shows possible adjustment for example

“New VlPsAdj = 1”

5. Press Up or Down key to make the reading 4ma current from the ampere

meter.

6. Press Enter.

Table of contents

Other intech 21 Controllers manuals

Popular Controllers manuals by other brands

Hathorn

Hathorn H12+ Operator's manual

National Instruments

National Instruments NI-488.2M user manual

Mitsubishi Electric

Mitsubishi Electric MELSEC iQ-R Series user manual

Timpdon Electronics

Timpdon Electronics GPRX7 quick start guide

Manley

Manley TUBES RULE ELOP owner's manual

Tusa

Tusa RS-340 owner's manual