9

Single-Duct and Retrofit Terminal Units IOM

the front sensor tap (away from the valve), and the low

pressure signal is delivered from the back line (near the

valve). The pressure differential between high and low

represents the amplified velocity pressure in the inlet

duct.

7. Read the differential pressure and enter the Krueger Inlet

Airflow Sensor Chart (Figure 6) to determine the airflow

in the terminal unit. For example, a differential pressure

of 0.10 in. wg for a size 8 unit yields an airflow of 290 cfm.

BALANCING PROCEDURE

(CONTROL SEQUENCES 1102 AND 1103)

Direct Acting Thermostat:

Normally Open Damper (Control Sequence 1102)

1. Minimum Volume Setting:

b. Disconnect the thermostat line from the volume

controller.

c. Adjust the minimum volume control knob (marked

LO and located in the center of the controller) to

achieve the required minimum flow. To determine the

required pressure differential, refer to Table 1, Table

2, and the Krueger Inlet Airflow Sensor Chart that is

provided on the side of the VAV unit and in Figure 6.

d. Reconnect the thermostat line.

2. Maximum Volume Setting:

c. Disconnect the thermostat line from the volume

controller.

d. Apply 15 + psi to the thermostat port on the volume

controller (marked “T”) by tapping into the main air

pressure line.

e. Adjust the maximum volume control knob (marked

HI and located at the side of the controller) until the

desired pressure differential is registered on the

manometer. To determine the required pressure

differential, refer to Table 1, Table 2, and the Krueger

Inlet Airflow Sensor Chart that is provided on the side

of the VAV unit and in Figure 6.

f. Reconnect the thermostat line.

Reverse Acting Thermostat:

Normally Closed Damper (Control Sequence 1103)

1. Maximum Volume Setting:

b. Disconnect the thermostat line from the velocity

controller.

c. Adjust the maximum volume control knob (marked

HI and located in the center of the controller) to

achieve the required minimum flow. To determine the

required pressure differential, refer to Table 1, Table

2, and the Krueger Inlet Airflow Sensor Chart that is

provided on the side of the VAV unit and in Figure 6.

d. Reconnect the thermostat line.

2. Minimum Volume Setting:

c. Disconnect the thermostat line from the velocity

controller.

d. Apply 15 + psi to the thermostat port on the volume

controller (marked “T”) by tapping into the main air

pressure line.

e. Adjust the minimum volume control knob (marked

LO and located at the side of the controller) until

the desired pressure differential is registered on

the manometer. To determine the required pressure

differential, refer to Table 1, Table 2, and the Krueger

Inlet Airflow Sensor Chart that is provided on the side

of the VAV unit and in Figure 6.

f. Reconnect the thermostat line.

BALANCING PROCEDURE

(CONTROL SEQUENCES 1104-1110)

1. Damper action is factory set at N.O. (normally open), or

N.C. (normally closed). To change perform the following

steps:

b. Loosen the damper selection screw.

c. Turn the selection dial clockwise until the NC or NO

arrow aligns with the DAMPER arrow.

NOTE: Accuracy in the alignment of the arrows is very

important. Make this adjustment as exact as possible.

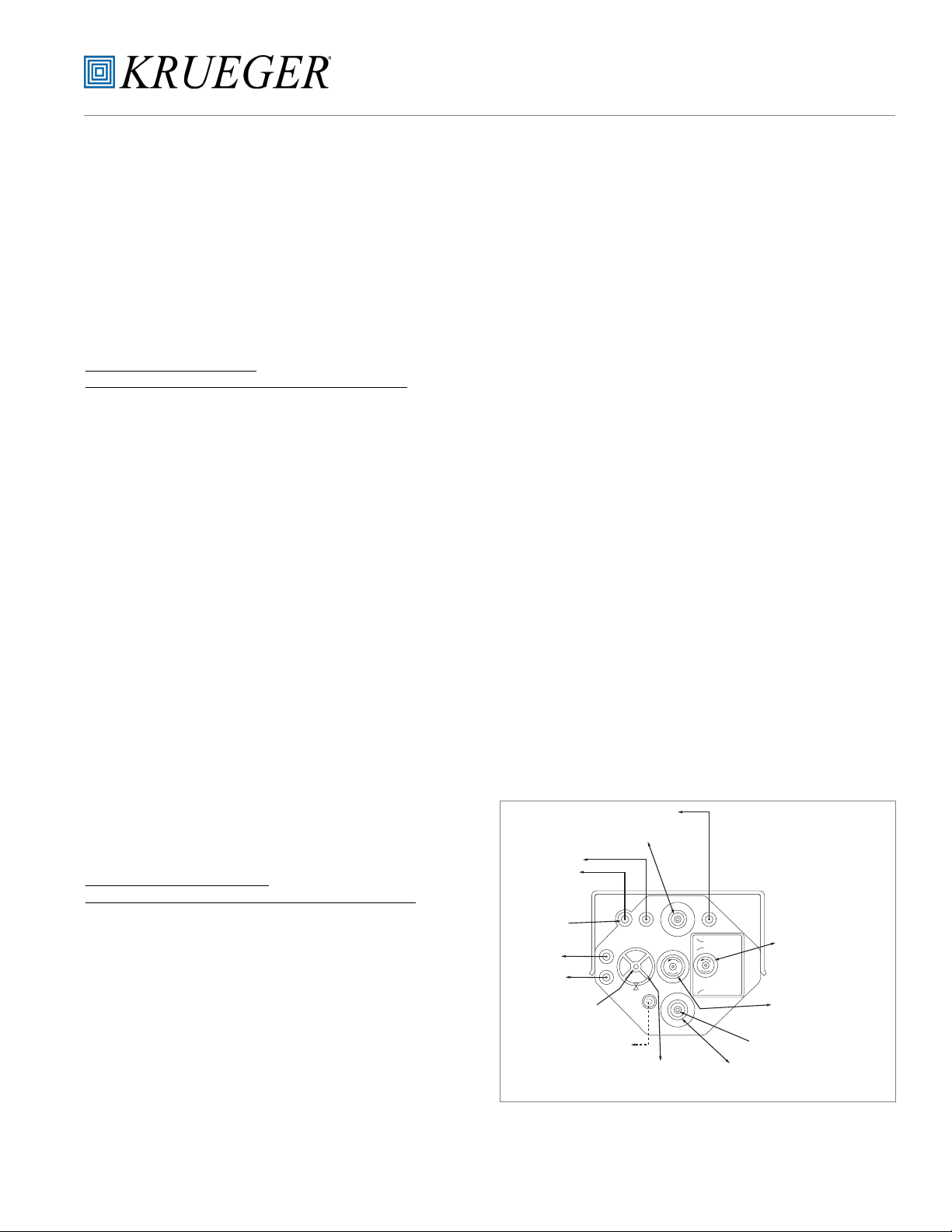

(See Figure 8)

4. Pipe the controller: Connect port “B” to the damper

actuator. Connect port “M” to the clean, dry main air.

Connect port “T” to the thermostat output. Connect

port “H” to the total pressure tap on the airflow sensor.

Connect port “L” to the static pressure tap on the airflow

sensor. The controller can be set up for cooling or heating

applications using either a Direct Acting (DA) or Reverse

Acting (RA) thermostat signal. The two flow adjustments

are labeled LO STAT ΔP and HI STAT ΔP.

TO THERMOSTAT BRANCH SIGNAL

(RESET SIGNAL)

RESET START POINT ADJUSTMENT

(FACTORY SET @ 8PSI)

TO STATIC PRESSURE

PUSH ON NIPPLES

FOR 3/16” (5) I.D.

FR TUBING (5) H L

T

B

M

G

WO

NC

TO DAMPER

ACTUATOR

DAMPER

HI STAT

LO STAT

RESET START

RESET SPAN

TO MAIN AIR

SUPPLY

LOOSEN SCREW TO

CHANGE DAMPER ACTION

(SUPPLIED IN N.O. POSITION)

GAUGE TAP. LEAVE CAP ON UNLESS

CONNECTING GAUGE FOR RESET

START OR RESET SPAN ADJUSTMENT

DAMPER ACTION SELECTION

(FACTORY SET @ NORMALLY OPEN)

NOTE: SCREW MUST BE TIGHT AND ARROWA

IN PERFECT ALIGNMENT FOR DEVICE TO FUNCTION PROPERLY.

DIFFERENTIAL PRESURE (FLOW)

LIMIT ADJUSTMENT WHEN T’STAT

PRESSURE IS HIGH (HI STAT)

(FACTORY SET @ 0.65” W.C.)

- FILED ADJUSTMENT REQUIRED

DIFFERENTIAL PRESURE (FLOW)

LIMIT ADJUSTMENT WHEN T’STAT

PRESSURE IS LOW (LO STAT)

(FACTORY SET @ 0” W.C.)

ALL ADJUSTMENT CCW TO INCREASE

(1/8”-5/32” FLATBLADE SCREWDRIVER)

RESET SPAN ADJUSTMENT

(FACTORY SET @ 5 PSI)

TO TOTAL PRESSURE

(DIFFERENCE IS DIFFERENTIAL

PRESSURE, OR DEVICE

VELOCITY PRESSURE)

Figure 8 – CSC 3011