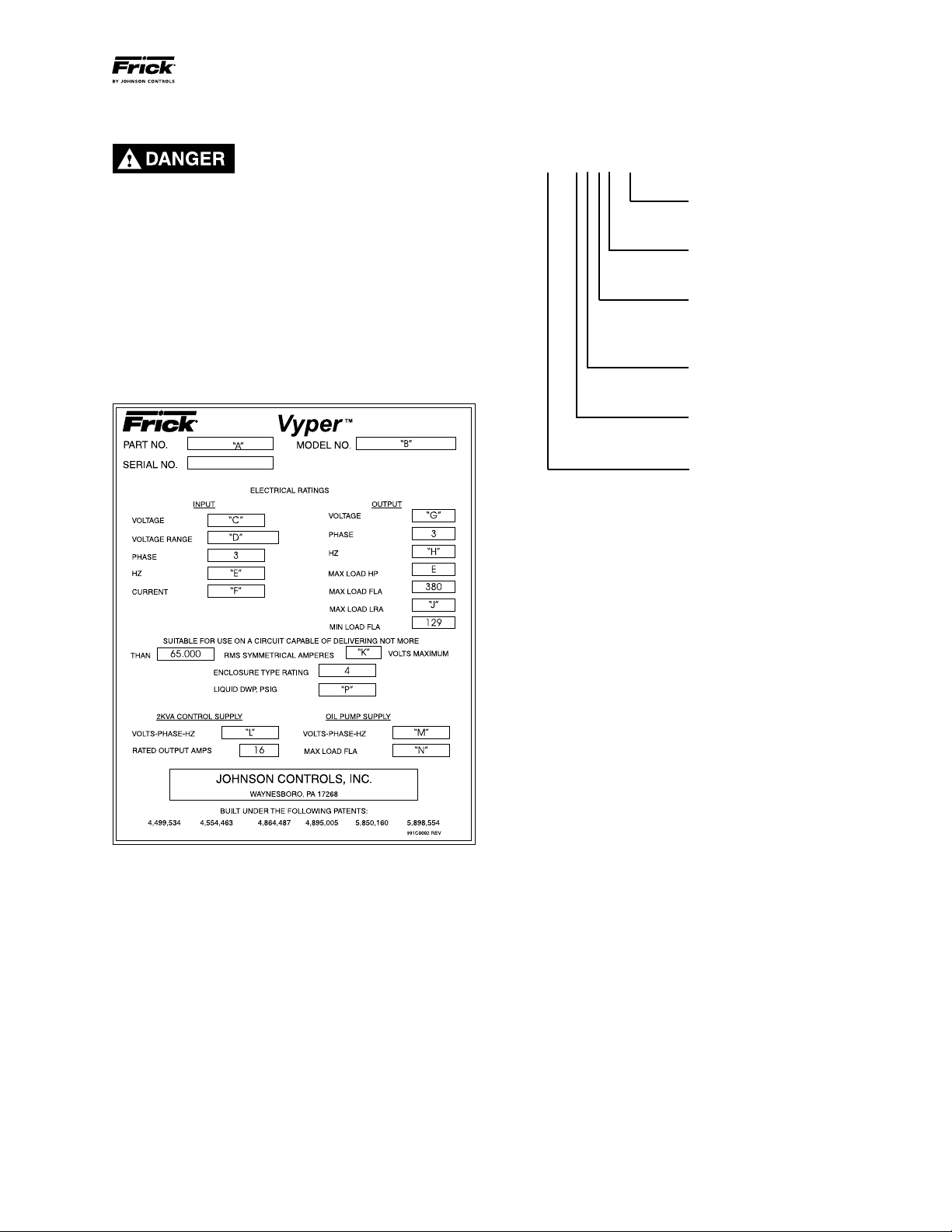

VYPER™VARIABLE SPEED DRIVE

INSTALLATION - OPERATION - MAINTENANCE

100-210 IOM (JUL 09)

Page 9

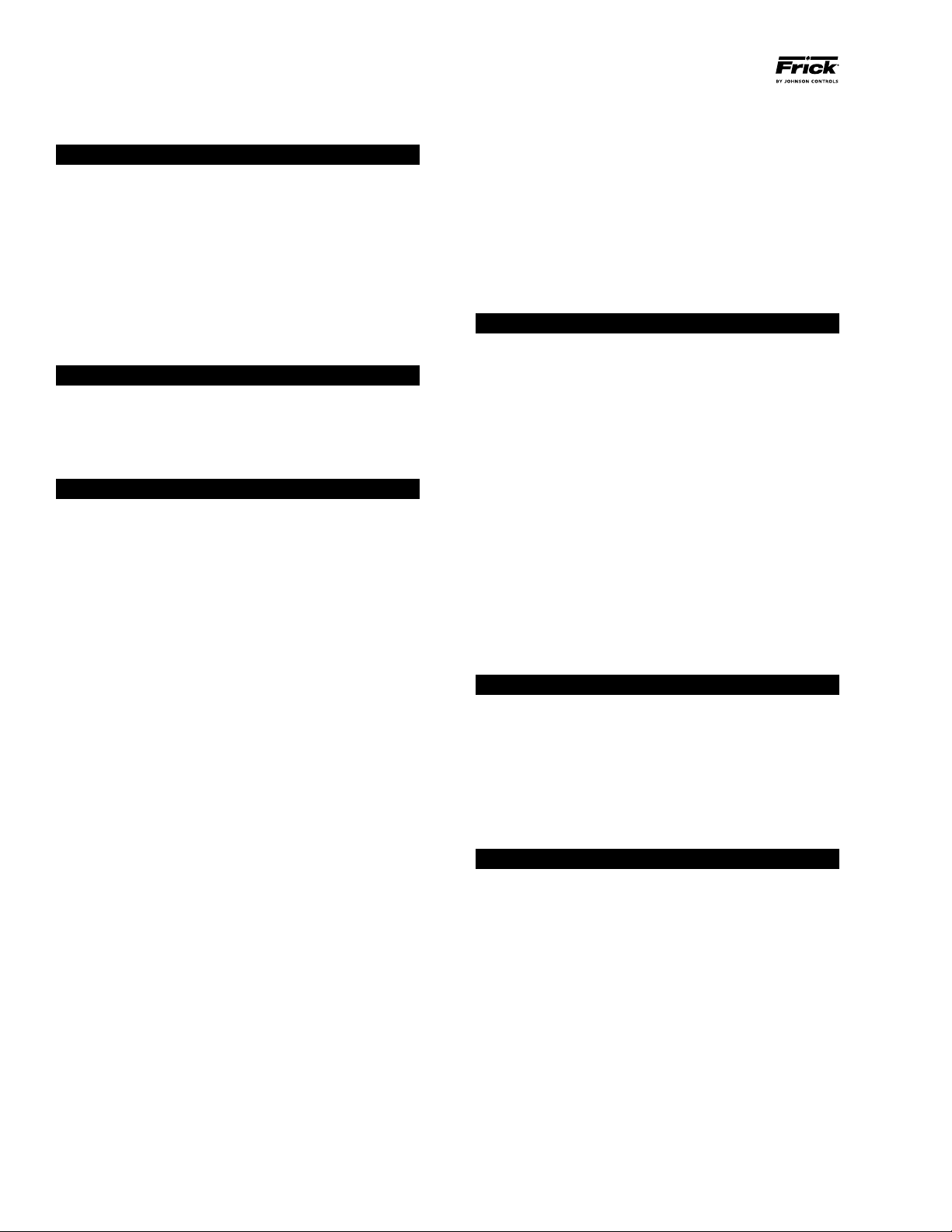

VYPER™SYSTEM OVERVIEW

VYPER™COMPONENT DESCRIPTION

The Frick Vyper™Variable Speed Drive is a liquid-cooled,

transistorized, PWM inverter in a highly integrated package.

This unit is factory designed to mount either remotely on a

stand or integrally to the compressor package. The power

section of the drive is composed of four major blocks:

• ACtoDCrectiersectionwithintegratedprechargecircuit

• DClinkltersection

• Three-phaseDCtoACinvertersection

• Outputsuppressionnetwork

An electronic circuit breaker with ground fault sensing con-

nects the AC line to an AC line choke and then to the DC

converter.The line choke will limit the amount of fault current

so that the electronic circuit breaker is sufficient for protecting

the Vyper™input fuses. See the elementary wiring diagram in

Figures 2A and 2B for wiring and component references.

The AC to DC Rectifier utilizes a semi-converter formed by

the connection of three SCR/diode modules (1SCR-3SCR)

in a three phase bridge configuration (See Figure 2). The

modules are mounted on a liquid cooled heatsink. Use of

the semiconverter configuration permits implementation of

a separate precharge circuit to limit the flow of current into

the DC link filter capacitors when the drive is switched on

and it also provides a fast disconnect from the power mains

when the drive is switched off. When the drive is turned off,

the SCRs in the semiconverter remain in a nonconducting

mode and the DC link filter capacitors remain uncharged.

When the drive is commanded to run, a set of precharge

resistors (1RES, 2RES) are switched into the circuit by con-

tactor 1M.The DC link filter capacitors are slowly charged via

the precharge resistors and the diodes of the semiconverter

for a fixed time period of fifteen (15) seconds.After the fifteen-

second time period has expired, the SCR’s are gated fully

on and the contactor 1M is dropped out.

A “free-wheeling” diode (1CR) is included to reduce the surge

current which must be conducted through the semiconverter

if a serious fault occurs across the DC link. Three (3) power

fuses (1FU - 3FU) and an electronic circuit breaker (1SW)

with ground fault sensing connects the AC to DC converter

to the power mains. The drive utilizes very fast semicon-

ductor power fuses to ensure that the SCR/diode module

packages do not rupture if a catastrophic failure occurs on

the DC link. The SCR Trigger board (031-01472) provides

the gating pulses for the SCR’s as commanded by the VSD

Logic board (031-02506).

The DC Link Filter section of the drive consists of two basic

components, a DC Link “smoothing” inductor or pair of induc-

tors (1L, 2L) and a series of electrolytic filter capacitors (C1-

C36). This inductor / capacitor combination forms a low-pass

L-C filter which effectively smooths the ripple voltage from

the AC to DC rectifier while simultaneously providing a large

energy reservoir for use by the DC to AC inverter section of

the drive. In order to achieve a suitable voltage capability

for the capacitor portion of the filter; filter capacitor “banks”

are formed by connecting two capacitors in series to form

a “pair”, and then paralleling a suitable number of “pairs” to

form a capacitor “bank”. In order to assure an equal sharing

of the voltage between the series connected capacitors and

to provide a discharge means for the capacitor bank when

the VSD is powered off, “bleeder” resistors (3RES and 4RES)

are connected across the capacitor banks.

The DC to AC Inverter section of the VSD (See Fig. 2),

serves to convert the rectified and filtered DC back to AC

at the magnitude and frequency commanded by the VSD

Logic board. The inverter section is actually composed of

three identical inverter output phase assemblies. These as-

semblies are in turn composed of a series of Insulated Gate

Bipolar Transistor (IGBT) modules (Q1-Q4) mounted to a

liquid cooled heatsink, a filter capacitor “bank” (C13-C20)

and a VSD Gate Driver board (031-01681) which provides

the On and Off gating pulses to the IGBT’s as determined

by the VSD Logic board.

In order to minimize the parasitic inductance between the

IGBT’s and the capacitor banks, copper plates which electri-

cally connect the capacitors to one another and to the IGBT’s

are connected together using a “laminated bus” structure.

This “laminated bus” structure is a actually composed of

a pair of copper bus plates with a thin sheet of insulating

material acting as the separator/insulator. The “laminated

bus” structure forms a parasitic capacitor which acts as a

small valued capacitor, effectively canceling the parasitic

inductance of the busbars themselves. To further cancel the

parasitic inductances, a series of small film capacitors (C43-

C51) are connected between the positive and negative plates

of the DC link. An IGBT driver “shield board” (031-01627),

mounted just beneath the VSD Gate Driver board, provides

electrical shielding for the Gate Driver board.

The VSD Output Suppression Network is composed of a

series of capacitors (C61-C66) and resistors (5RES-10RES)

connected in a three phase delta configuration. The param-

eters of the suppression network components are chosen

to work in unison with the parasitic inductance of the DC to

AC inverter sections in order to simultaneously limit both the

rate of change of voltage and the peak voltage applied to

the motor windings. Limiting the peak voltage to the motor

windings, as well as the rate-of-change of motor voltage avoid

problems commonly associated with PWM motor drives,

such as stator-winding end-turn failures and electrical fluting

of motor bearings.

Various ancillary sensors and boards are used to convey

information back to the VSD Logic board. The following list

describes some of these components.

• Eachliquid-cooledheatsinkwithintheDCtoACinverter

section contains a thermistor heatsink temperature sensor

(RT1 - RT3) to provide temperature information to the VSD

logic board.

• TheACtoDCsemiconverterheatsinktemperaturemoni-

tored using a thermistor temperature sensor (RT4).

• Thebus isolator board (031-01624) utilizes three resistors

on the board to provide a “safe” impedance between the

DC link filter capacitors located on the output phase bank

assemblies and the VSD logic board. The bus isolator

board provides the means to sense the positive, midpoint,

and negative connection points of the VSD’s DC link.

• ACurrentTransformer(3T-5T)isincludedoneachoutput

phase assembly to provide motor current information to

the VSD logic board.