8| Krystal Pure™ | Reverse Osmosis System Manual

2. Open the tank ball valve by turning handle a ¼

turn toward the tubing. Let tank fill for 4 to 6

hours (if you are changing filters, your tank may

already be full, so you would not need to wait).

Then turn on R/O faucet and drain tank com-

pletely, (approx. 5 minutes). Shut R/O faucet

off, allow tank to refill, and drain again in 4 to

6 hours. The R/O system is shipped with a food

grade preservative and must be flushed out pri-

or to use. DO NOT DRINK THE R/O WATER

UNTIL TANK HAS BEEN DRAINED TWICE.

3. Shut R/O faucet off and let system fill again.

R/O water is now ready for use.

IMPORTANT: Check carefully for small leaks every

few hours for the first few days to assure there are

no leaks. It is wise on any R/O system to inspect for

leaks since the system sits unseen underneath your

sink and a small leak may not be detected with-

out close inspection. Check for leaks occasionally

thereafter and make adjustments as necessary

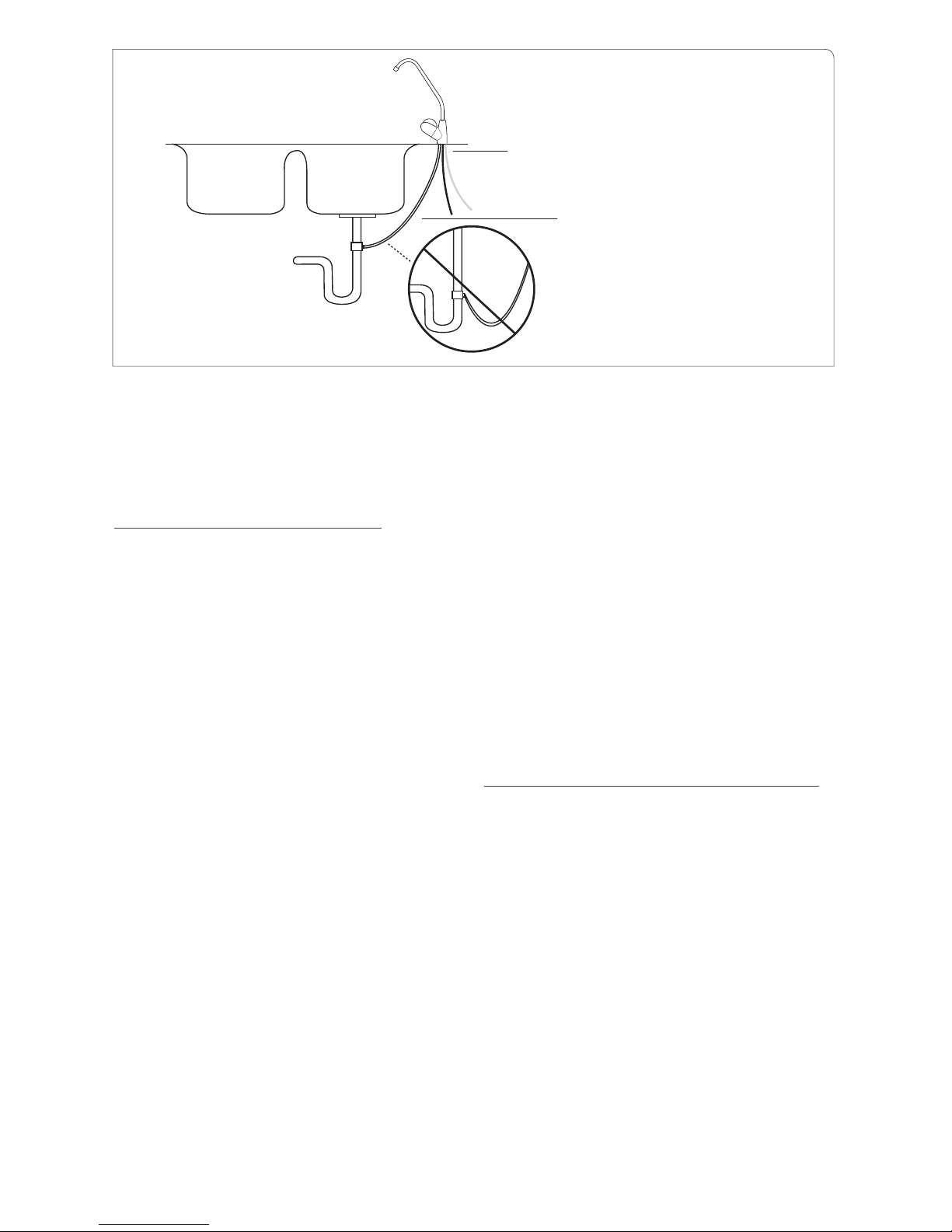

STEP 8 REFRIGERATOR ICE MAKER

HOOK UP

1. If there is not an ice-line from the R/O to the

refrigerator, you may choose to run an ice-line

so that your ice and water dispenser will have

filtered water. If the distance from the refrig-

erator to the R/O is more than 50 ft., we rec-

ommend 3/8” polypropylene or polyethylene

tubing for best results. DO NOT USE COPPER

(Be sure you have the recommended water

pressure to your ice maker according to the

refrigerator manufacturer’s specifications.) 3/8”

tubing, a supplemental storage tank, more R/O

air pressure, or different usage patterns, may be

required to supply adequate pressure!

2. Connect tube (not included) to appropriate re-

frigerator connection and to a plastic “T” fitting

(not included) spliced into the 3/8” blue tube

between the post filter and faucet. It is recom-

mended to install a ball valve on the tube to the

refrigerator for service and start up purposes.

Keep ball valve off until start up procedures are

completed and R/O tank is completely full after

the second tank draining.

IMPORTANT: Never turn on icemaker before

R/O tank is full of water to avoid damaging refrig-

erator solenoid. If your refrigerator has a water

dispenser in the door, upon initial start-up you

will need to depress the water supply lever 2 to 3

minutes before the water will dispense.

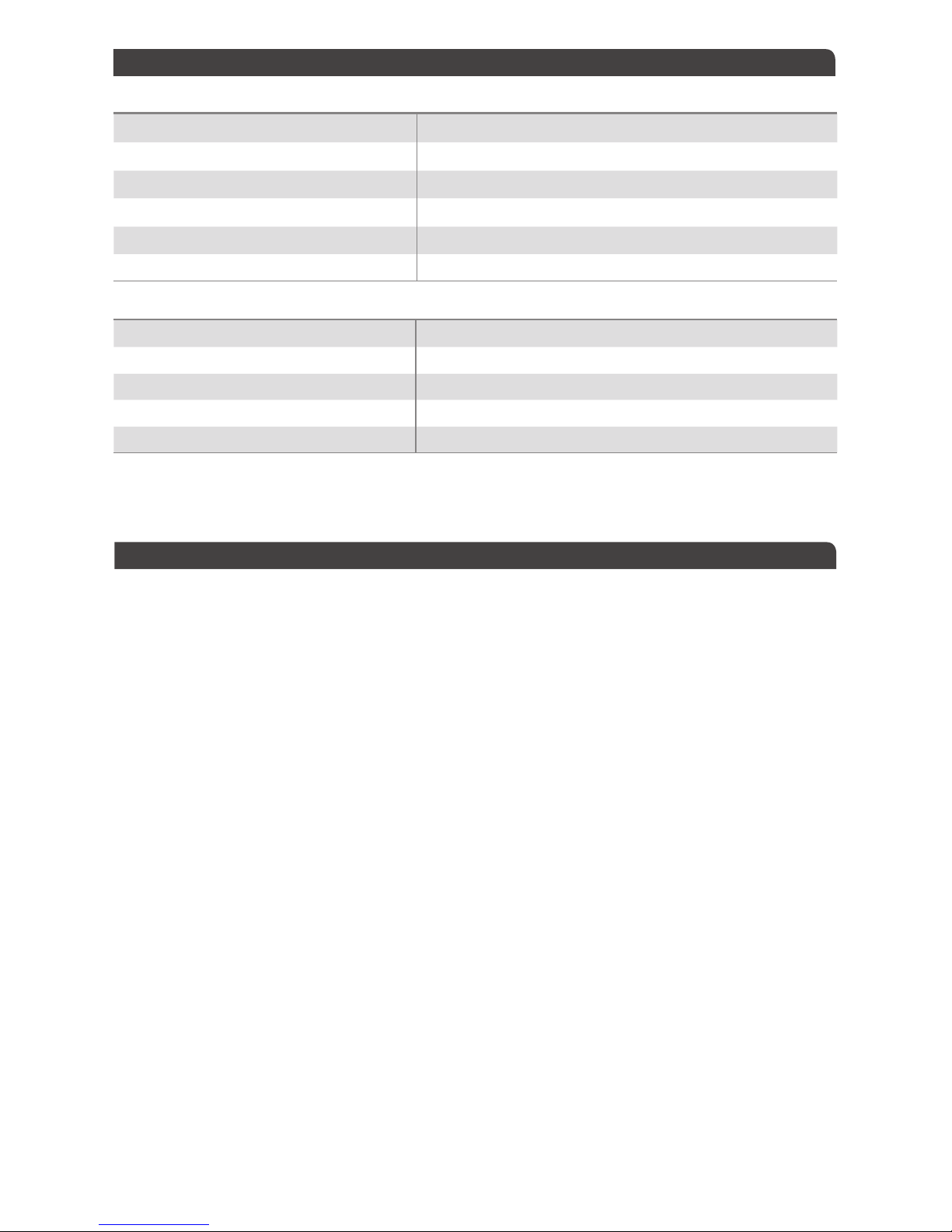

STEP 9 RECOMMENDED FILTER

SERVICE LIFE

The types of filters listed below vary depending

on R/O system style. The manufacturer provides

very high capacity carbon filters and replace-

ment intervals are based on our filters. Other

filters may not have the same capacity as origi-

nal factory filters and may not last as long. Water

conditions vary greatly by region and can affect

filter change intervals. For filter change interval

recommendations, follow the guidelines below.

If in doubt, contact the manufacturer.

Sediment Pre-filter: These are the only filter(s)

that you can visually inspect. They are white

when new and will turn dark with dirt and sedi-

ment when changing is necessary. A water soft-

ener will extend the life of the filter(s). Inspect ev-

ery 6 months or sooner in bad water conditions.

Carbon Pre-filter: These filters should be

changed at least once a year. Changing these fil-

ters is necessary to help insure membrane life and

water quality. Use of high capacity carbon block

filters is recommended. Granular carbon filters

are not recommended because they release ex-

cessive carbon fines at initial start-up, which can

reduce the life of the membrane element.

R/O Membrane: The R/O membrane element is

a replaceable component critical for effective re-

duction of TDS (Total Dissolved Solids). The R/O

membrane should be changed when TDS rejection

rate falls below 75%. The rejection rate should be

tested periodically to insure optimal performance.

The membrane typically lasts 2-5 years depending

on influent water quality and hardness. See perfor-

mance indicator information listed below.*

Carbon Post-filter/Carbon M.A.P.™ Filter: These

filters need to be changed at least every 12

months to insure quality water. Do not wait until

taste is a problem.

*Performance indicator. The R/O system contains

a replaceable treatment component critical for ef-

fective reduction of TDS (Total Dissolved Solids).

The product water shall be tested periodically to

verify that the system is performing properly. Test-

ing can be accomplished by contacting the service

company that installed your R/O system or an au-

thorized dealer. If a service company is not avail-

able in your area a water sample may be sent to

AmeriFlow™ for a free TDS test of your R/O water.

Additionally a water quality monitor is available

for purchase from the manufacturer that will allow

the product water to be tested at home.

To send water samples for TDS testing to the man-

ufacturer do the following. Using 2 clean contain-

ers put approximately ½ cup of tap water in one