Contents

3 of 44

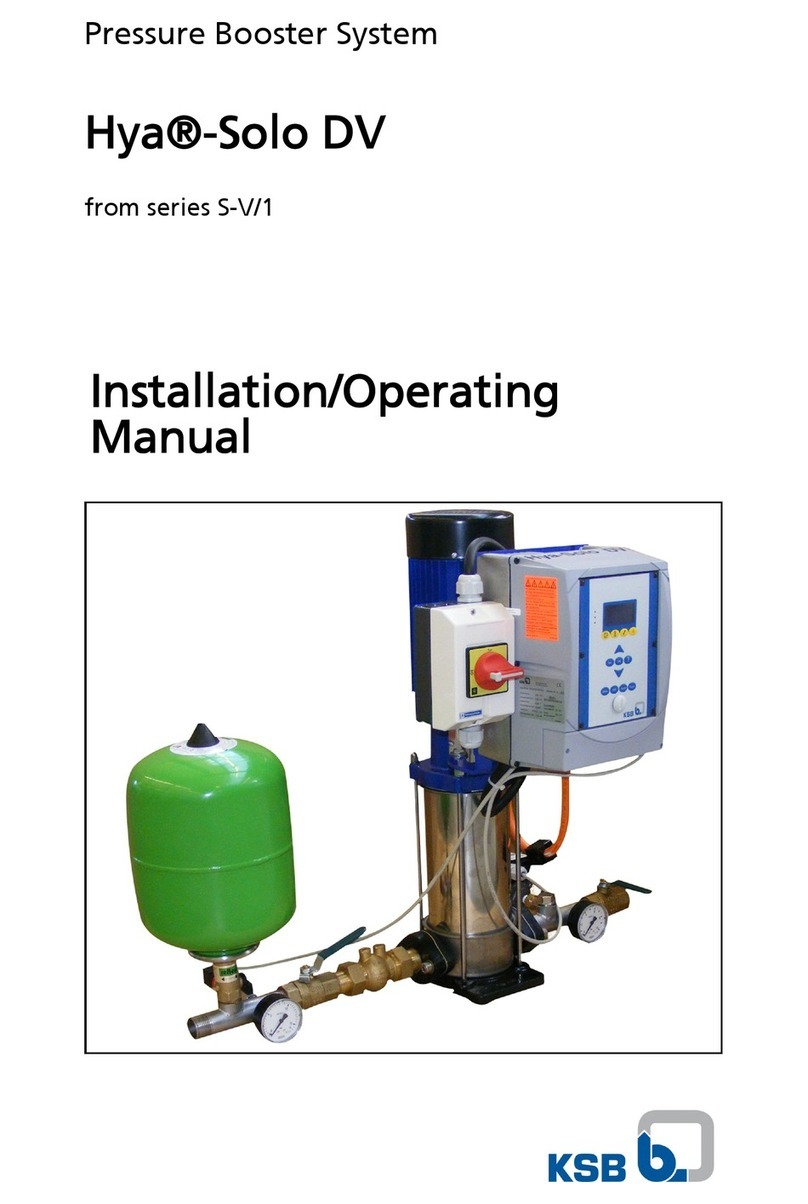

Hya-Solo D

Contents

Glossary .................................................................................................................................................. 5

1 General.................................................................................................................................................... 6

1.1 Principles ...........................................................................................................................................................6

1.2 Installation of partly completed machinery....................................................................................................6

1.3 Target group.....................................................................................................................................................6

1.4 Other applicable documents............................................................................................................................6

1.5 Symbols .............................................................................................................................................................6

1.6 Key to safety symbols/markings.......................................................................................................................7

2 Safety...................................................................................................................................................... 8

2.1 General..............................................................................................................................................................8

2.2 Intended use .....................................................................................................................................................8

2.3 Personnel qualification and personnel training.............................................................................................8

2.4 Consequences and risks caused by non-compliance with this manual .........................................................9

2.5 Safety awareness ..............................................................................................................................................9

2.6 Safety information for the operator/user.......................................................................................................9

2.7 Safety information for maintenance, inspection and installation ................................................................9

2.8 Unauthorised modes of operation................................................................................................................10

3 Transport/Storage/Disposal ................................................................................................................ 11

3.1 Checking the condition upon delivery..........................................................................................................11

3.2 Transport.........................................................................................................................................................11

3.3 Storage/preservation......................................................................................................................................12

3.4 Return to supplier ..........................................................................................................................................12

3.5 Disposal ...........................................................................................................................................................13

4 Description............................................................................................................................................ 14

4.1 General description ........................................................................................................................................14

4.2 Product information as per Regulation No. 1907/2006(REACH).................................................................14

4.3 Designation.....................................................................................................................................................14

4.4 Name plate......................................................................................................................................................14

4.5 Design details..................................................................................................................................................15

4.6 Configuration and function...........................................................................................................................16

4.7 Noise characteristics .......................................................................................................................................17

4.8 Scope of supply...............................................................................................................................................17

4.9 Dimensions and weights ................................................................................................................................17

5 Installation at Site................................................................................................................................ 18

5.1 Checks to be carried out prior to installation...............................................................................................18

5.2 Installing the pressure booster system..........................................................................................................19

5.3 Mounting the accumulator............................................................................................................................20

5.4 Connecting the piping ...................................................................................................................................20

5.4.1 Fitting an expansion joint (optional)................................................................................................21

5.4.2 Fitting the pressure reducer (optional) ............................................................................................21

5.5 Electrical connection ......................................................................................................................................22

5.5.1 Sizing the power cable ......................................................................................................................23

5.5.2 Connecting the pressure booster system..........................................................................................23

5.5.3 Connecting the dry running protection device................................................................................23

6 Commissioning/Start-up/Shutdown................................................................................................... 24

6.1 Commissioning/Start-up.................................................................................................................................24

6.1.1 Prerequisites for commissioning/start-up .........................................................................................24

6.1.2 Priming and venting the pressure booster system...........................................................................24

6.1.3 Setting the dry running protection device.......................................................................................25

6.1.4 Start-up...............................................................................................................................................26

6.1.5 Checklist for commissioning/start-up................................................................................................26