Caution

Hyamat K

5

Immediately following completion of the work, all

safety-relevant and protective devices must be re-installed

and / or re-activated.

Please observe all instructions set out in the chapter on

”Commissioning / start-up” before returning the unit to service.

2.7 Unauthorized modification and

manufacture of spare parts

Modifications or alterations of the equipment supplied are only

permitted after consultation with the manufacturer. Original

spare parts and accessories authorized by the manufacturer

ensure safety. The use of other parts can invalidate any liability

of the manufacturer for resulting damage.

2.8 Unauthorized modes of operation

The warranty relating to the operating reliability and safety of

the unit supplied is only valid if the equipment is used in

accordance with its designated use (see section 4). The limits

stated in the data sheet must not be exceeded under any

circumstances.

3 Transport and interim storage

The package unit is packaged on pallets or in wooden crates

and wrapped in plastic foil for shipping and interim storage. All

connecting points are capped. It is imperative that the

shipping / handling instructions shown on the package be

followed.

The unit must be protected against frost.

If upon unpackaging the unit you should discover that the

package has been damaged by dropping or some other form of

mechanical impact, please carefully inspect the unit itself for

possible damage and inform the freight forwarder / KSB’s

customer service, even if you have not been able to detect any

such damage.

Once the unit has been removed from the package, it must be

stored in accordance with the location and installation

instructions (see Installation and location).

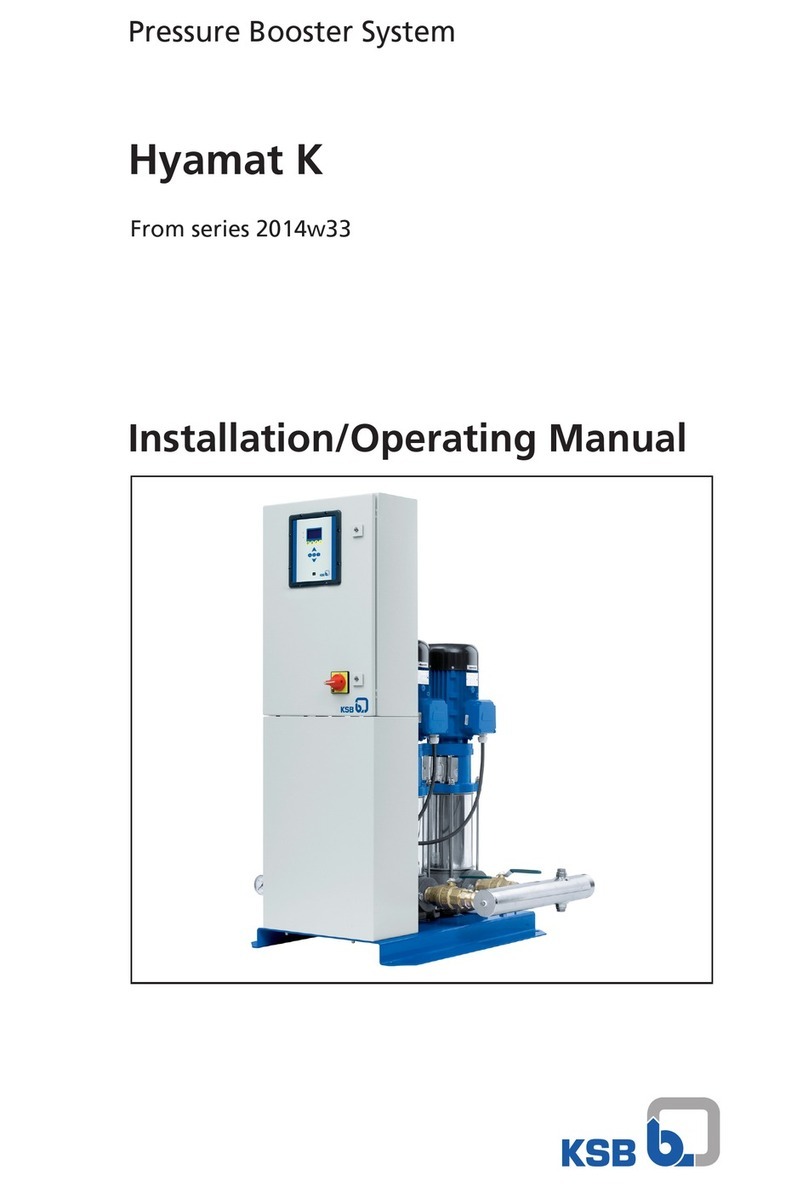

4 Description

4.1 General description

The fully electronic pressure boosting package units are

supplied ready for connection.

The equipment circuitry allows both direct and indirect

connection to the water supply system.

For combined use as drinking water supply and fire protection

system, Hyamat K can be installed as an interconnected

system in accordance with DIN 1988, Part 5.

The equipment must be operated and maintained in

accordance with DIN 1988 (DVGW) so as to ensure

uninterrupted reliability of water supply, without causing

disturbances in the public water supply or other consumer

supply systems.

The instructions put forth in DIN 1988 must be adhered to for

connection to the public water supply system; any applicable

water utility or fire protection regulations must also be

complied with.

Furthermore, local conditions must be taken into account (for

example excessive or very unsteady supply pressure requiring

the installation of a pressure reducer).

4.2 Configuration and function

4.2.1 Configuration

Between 2 and 6 vertical high-pressure pumps (for description

and function, please refer to the pump’s Operating Instructions)

are arranged on a baseplate.

Each pump is installed on its own anti-vibration mounts.

Pumps connected in series are coupled by stainless steel

pipes.

On the system side, a combined non-return and shut-off valve

(KFR) or a swing check valve and a shut-off butterfly valve are

fitted downstream of each pump.

On the suction side, a ball valve or a shut-off butterfly valve are

fitted upstream of each pump as a service valve.

The shut-off elements permit dismantling of individual pumps

without having to drain the pipework. The discharge side

non-return valve ensures that the system remains filled with

water and prevents backflow through the pumps.

Both distributor pipes feature additional connections for

draining, venting and installation of various dry running

protection devices.

The surge vessel (accumulator) is fitted with an isolating valve.

It compensates discharge-side peak pressures and, together

with the minimum operating period, limits the pumps’ switching

frequency.

Hyamat K units are switched on as a function of pressure. To

this effect, a pressure transmitter is fitted in the discharge-side

piping.

Depending on the number and performance of the pumps, the

completely wired control cabinet is either supplied mounted on

the baseplate or as a free-standing cabinet.

Only additional and special equipment is already fitted on the

system.

Accessories such as expansion joints, tanks, accumulators,

pressure reducers etc. are supplied with the unit but are not

mounted.

The unit is driven by surface-cooled three-phase squirrel-cage

motors, 50 Hz, air-cooled, 2-pole, KSB standardized motor with

main dimensions to IEC. Other motor makes after consultation

with KSB,

up to 2.2 kW 220--240 V/380--420 V,

from 3 kW 380--420 V/660--725 V

enclosure IP 55, thermal class F, up to 4 kW design V18,

from 5.5 kW design V1, all motors>3kWwithPTCthermistor.

4.2.2 Function

The Hyamat unit is switched on and off as a function of the

pressure. The start-up pressure pEand the switch-off pressure

pAare derived from the adjustable set value psoll and the

adjustable hysteresis.

pE=p

soll -- hysteresis, pA=p

soll + hysteresis.

Automatic mode

The unit consisting of 2 to 6 pumps starts the first pump when

the pressure falls below the start-up pressure pE.

When the start-up pressure is reached, a minimum operating

period of 3 minutes is activated.

If this pump meets the current demand and if a pressure > pE

and < pAis maintained, the pump operates until the demand

drops and the switch-off pressure pAis reached.

If the first pump cannot meet the demand, the pressure will fall

below pEagain, and the next pump available is started after a

cut-in delay period of 2 seconds.

This routine is repeated until all pumps are running.

If the unit has been correctly selected in accordance with DIN

1988, the demand will be covered without using the stand-by

pump.

As demand decreases, the pumps are automatically

sequenced out after their minimum operating period and a

cut-out delay of 2 seconds. The pump that was started up first

will be switched off first.

In order to ensure equal distribution of pump operating hours,

the pumps will be changed for the next start-up cycle.

The operating status is displayed via LEDs.