Contents

3 of 68

KSBDeltaSolo / KSBDeltaEco

Contents

Glossary .................................................................................................................................................. 5

1 General.................................................................................................................................................... 6

1.1 Principles ...........................................................................................................................................................6

1.2 Installation of partly completed machinery....................................................................................................6

1.3 Target group.....................................................................................................................................................6

1.4 Other applicable documents............................................................................................................................6

1.5 Symbols .............................................................................................................................................................6

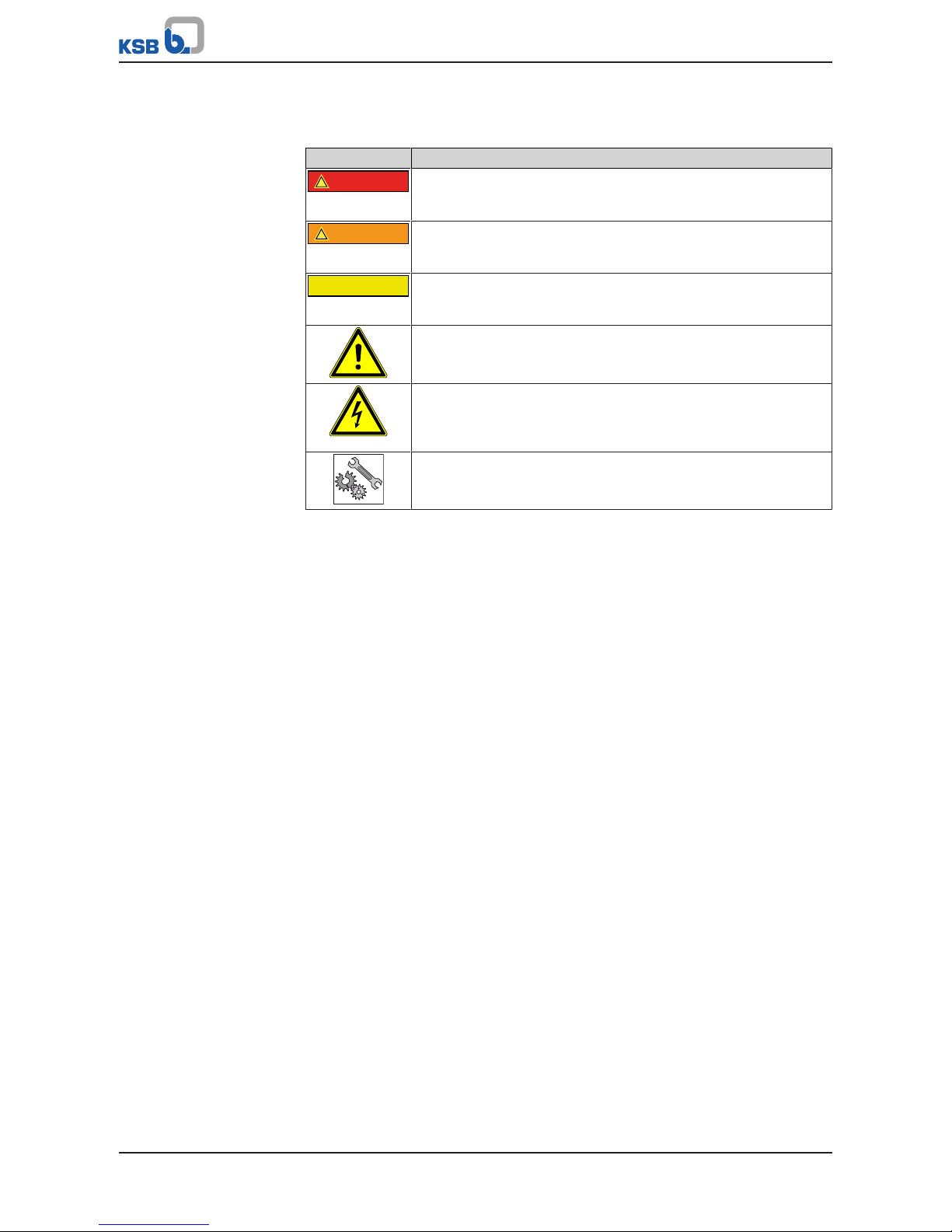

1.6 Key to safety symbols/markings.......................................................................................................................7

2 Safety...................................................................................................................................................... 8

2.1 General..............................................................................................................................................................8

2.2 Intended use .....................................................................................................................................................8

2.2.1 Prevention of foreseeable misuse.......................................................................................................8

2.3 Personnel qualification and personnel training.............................................................................................8

2.4 Consequences and risks caused by non-compliance with this manual .........................................................9

2.5 Safety awareness ..............................................................................................................................................9

2.6 Safety information for the operator/user.......................................................................................................9

2.7 Safety information for maintenance, inspection and installation ................................................................9

2.8 Unauthorised modes of operation................................................................................................................10

2.9 Electromagnetic compatibility (EMC)............................................................................................................10

2.9.1 Interference emission requirements .................................................................................................10

2.9.2 Line harmonics requirements............................................................................................................11

2.9.3 Interference immunity requirements ...............................................................................................11

3 Software Changes................................................................................................................................ 12

4 Transport/Temporary Storage/Disposal............................................................................................. 13

4.1 Checking the condition upon delivery..........................................................................................................13

4.2 Transport.........................................................................................................................................................13

4.3 Storage/preservation......................................................................................................................................13

4.4 Return to supplier ..........................................................................................................................................14

4.5 Disposal ...........................................................................................................................................................14

5 Description............................................................................................................................................ 15

5.1 General description ........................................................................................................................................15

5.2 Designation.....................................................................................................................................................15

5.3 Name plate......................................................................................................................................................15

5.4 Design details..................................................................................................................................................15

5.5 Configuration and function...........................................................................................................................16

5.6 Noise characteristics .......................................................................................................................................17

5.7 Scope of supply...............................................................................................................................................17

5.8 Dimensions......................................................................................................................................................18

5.9 Terminal wiring diagram ...............................................................................................................................18

5.10 Potential equalisation ....................................................................................................................................18

6 Installation at Site................................................................................................................................ 19

6.1 Installation ......................................................................................................................................................19

6.2 Checks to be carried out prior to installation...............................................................................................19

6.3 Installing the pressure booster system..........................................................................................................19

6.4 Installing the piping .......................................................................................................................................20

6.4.1 Fitting an expansion joint .................................................................................................................20

6.4.2 Installing a pressure reducer .............................................................................................................21

6.5 Installing unpressurised inlet tanks...............................................................................................................21

6.6 Fitting the dry running protection device ....................................................................................................22

6.7 Connection to power supply..........................................................................................................................23

6.7.1 Sizing the power cable ......................................................................................................................23