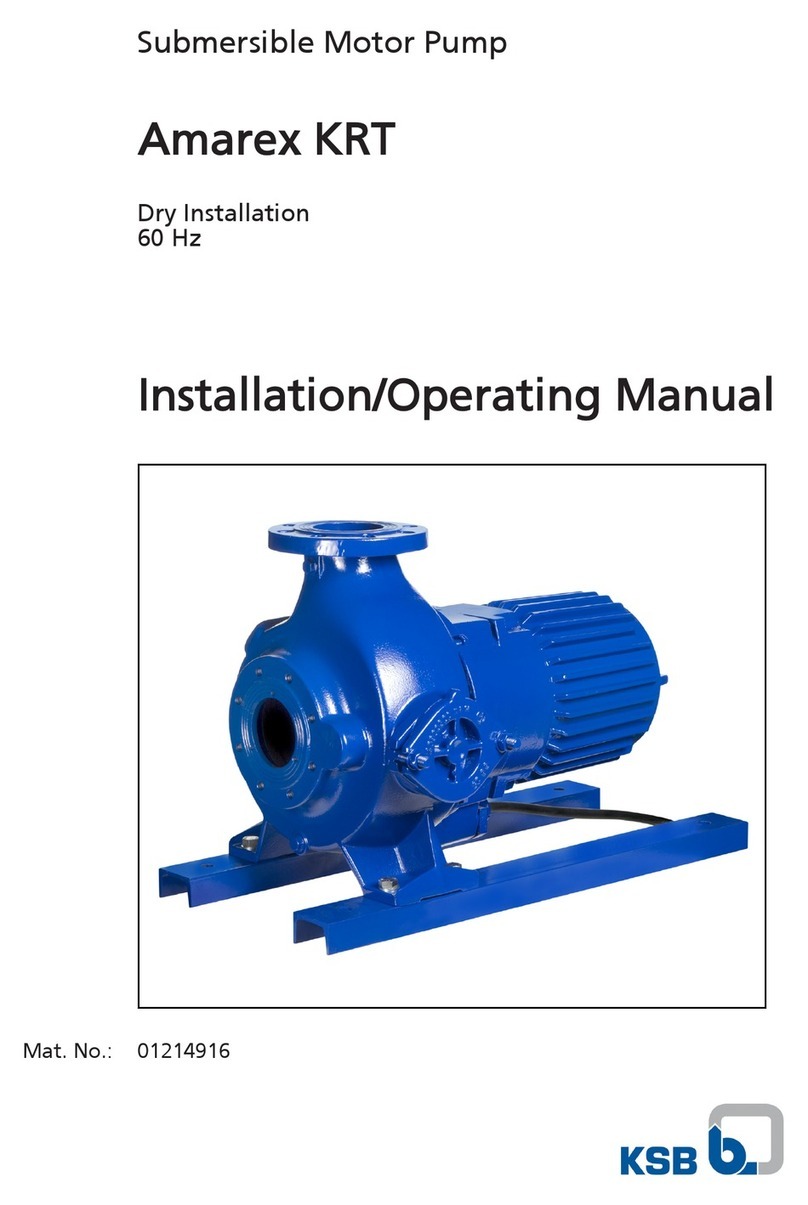

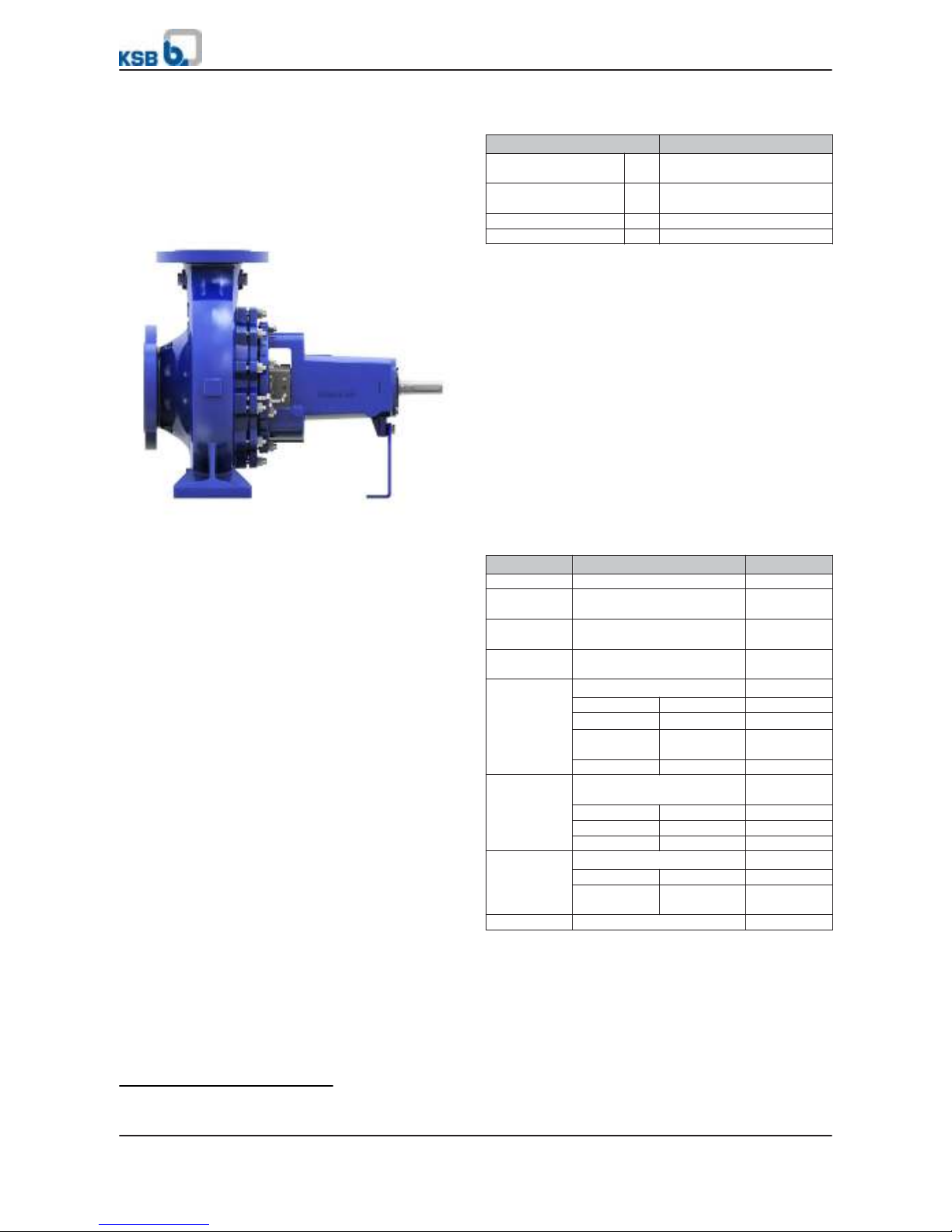

▪Operating costs reduced by trimming the impeller

diameter to match the specified duty point

▪Little wear, low vibration levels and excellent smooth

running characteristics thanks to good suction

performance and virtually cavitation-free operation across

a wide operating range

▪Casing sealed reliably – even in varying operating

conditions – by confined casing gasket

▪Optimum material selection for the specific fluid handled

by a large variety of materials. Large range of materials

for many applications available as a standard.

▪Extended selection chart with additional pump sizes for

small flow rates

▪Easy to dismantle with forcing screws provided at the

interface of casing cover and bearing bracket

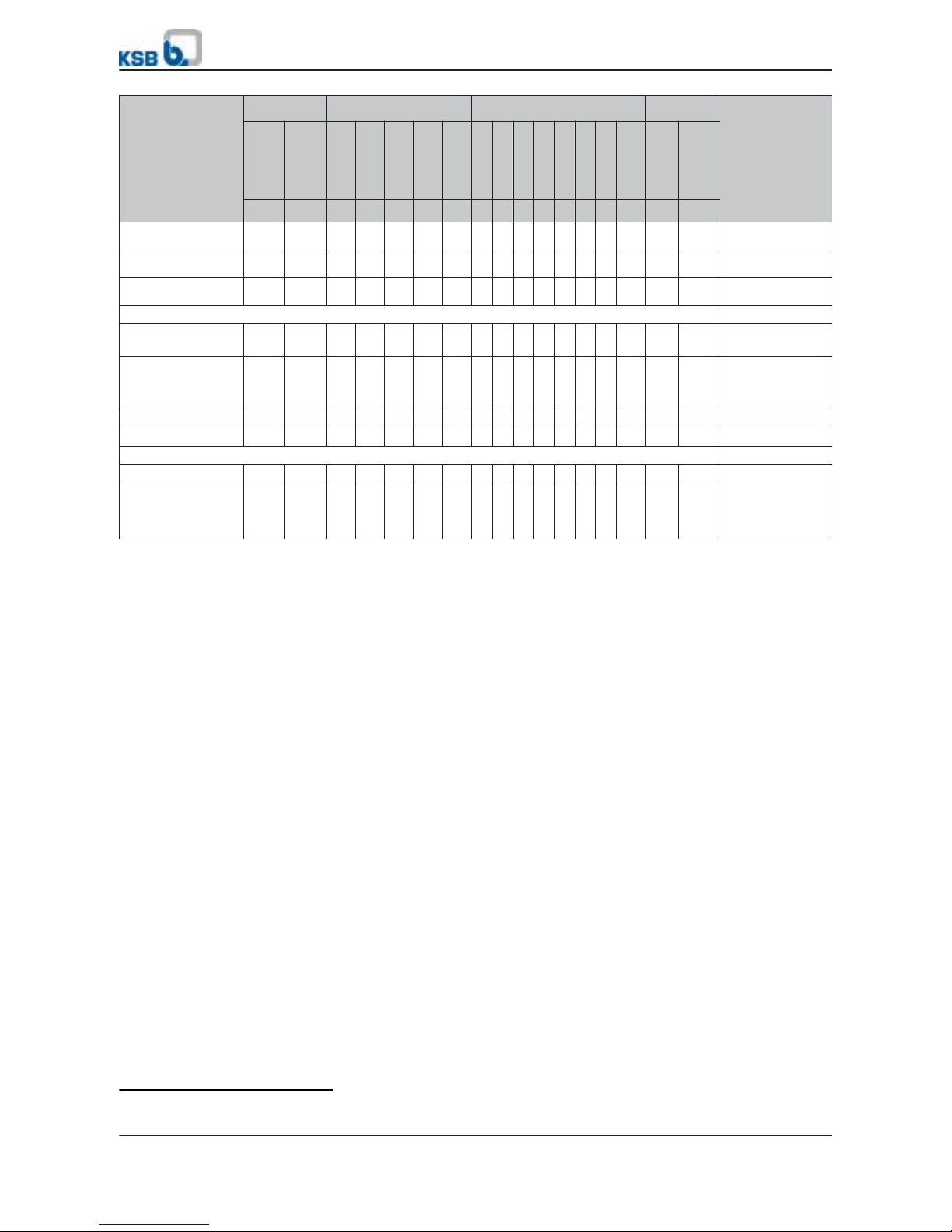

Product Information as per Regulation No. 547/2012 (for

Water Pumps with a Maximum Shaft Power of 150 kW)

Implementing "Ecodesign" Directive 2009/125/EC

▪Minimum efficiency index: see data sheet

▪The benchmark for most efficient water pumps is MEI ≥

0.70.

▪Year of construction: see data sheet

▪Manufacturer’s name or trade mark, commercial

registration number and place of manufacture: see data

sheet or order documentation

▪Product’s type and size identificator: see data sheet

▪Hydraulic pump efficiency (%) with trimmed impeller: see

data sheet

▪Pump performance curves, including efficiency

characteristics: see documented characteristic curve

▪The efficiency of a pump with a trimmed impeller is

usually lower than that of a pump with full impeller

diameter. Trimming of the impeller will adapt the pump

to a fixed duty point, leading to reduced energy

consumption. The minimum efficiency index (MEI) is based

on the full impeller diameter.

▪Operation of this water pump with variable duty points

may be more efficient and economic when controlled, for

example, by the use of a variable speed drive that matches

the pump duty to the system.

▪Information relevant for disassembly, recycling or disposal

at end of life: see installation/operating manual

▪Information on benchmark efficiency or benchmark

efficiency graph for MEI = 0.7 (0.4) for the pump based on

the model shown in the Figure are available at: http://

www.europump.org/efficiencycharts

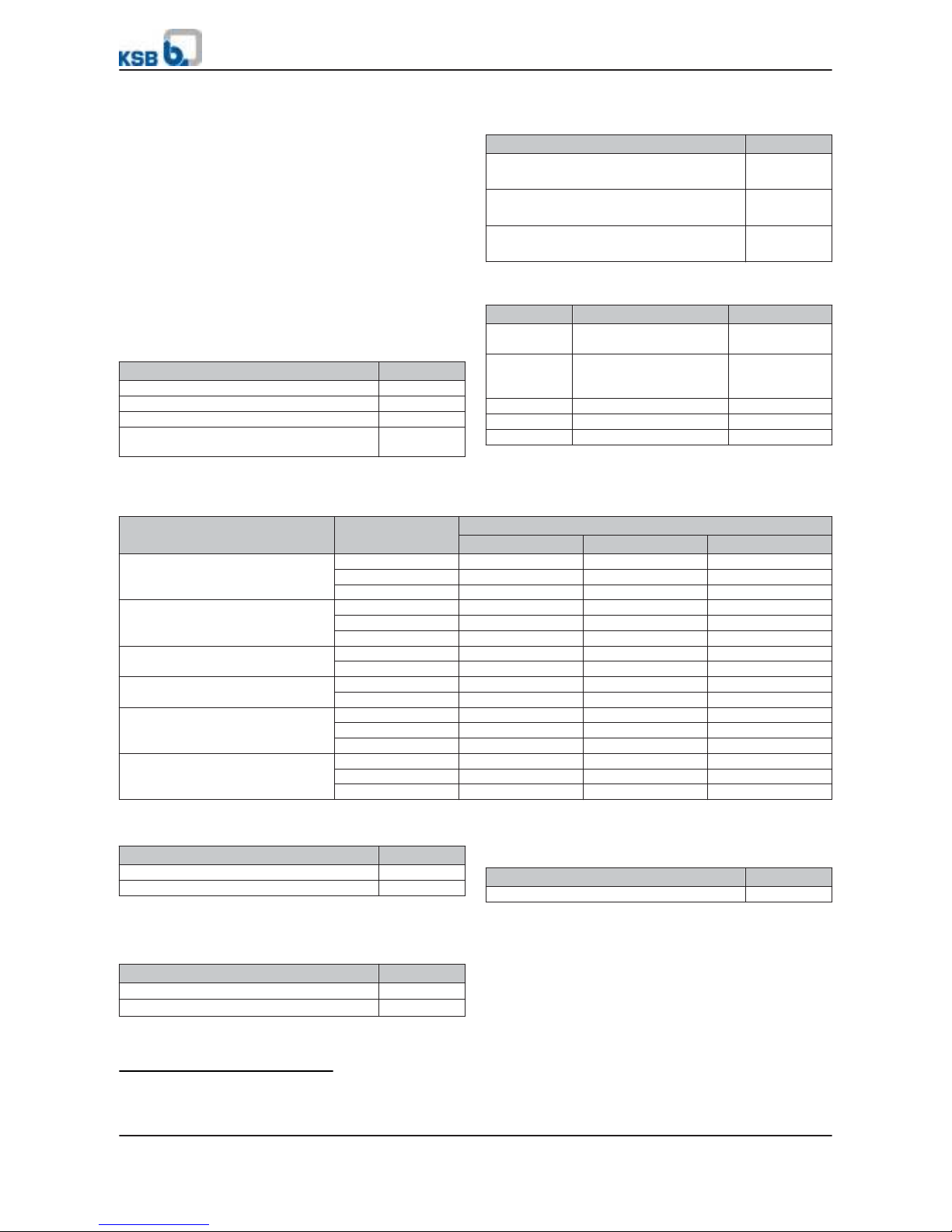

Acceptance tests/warranty

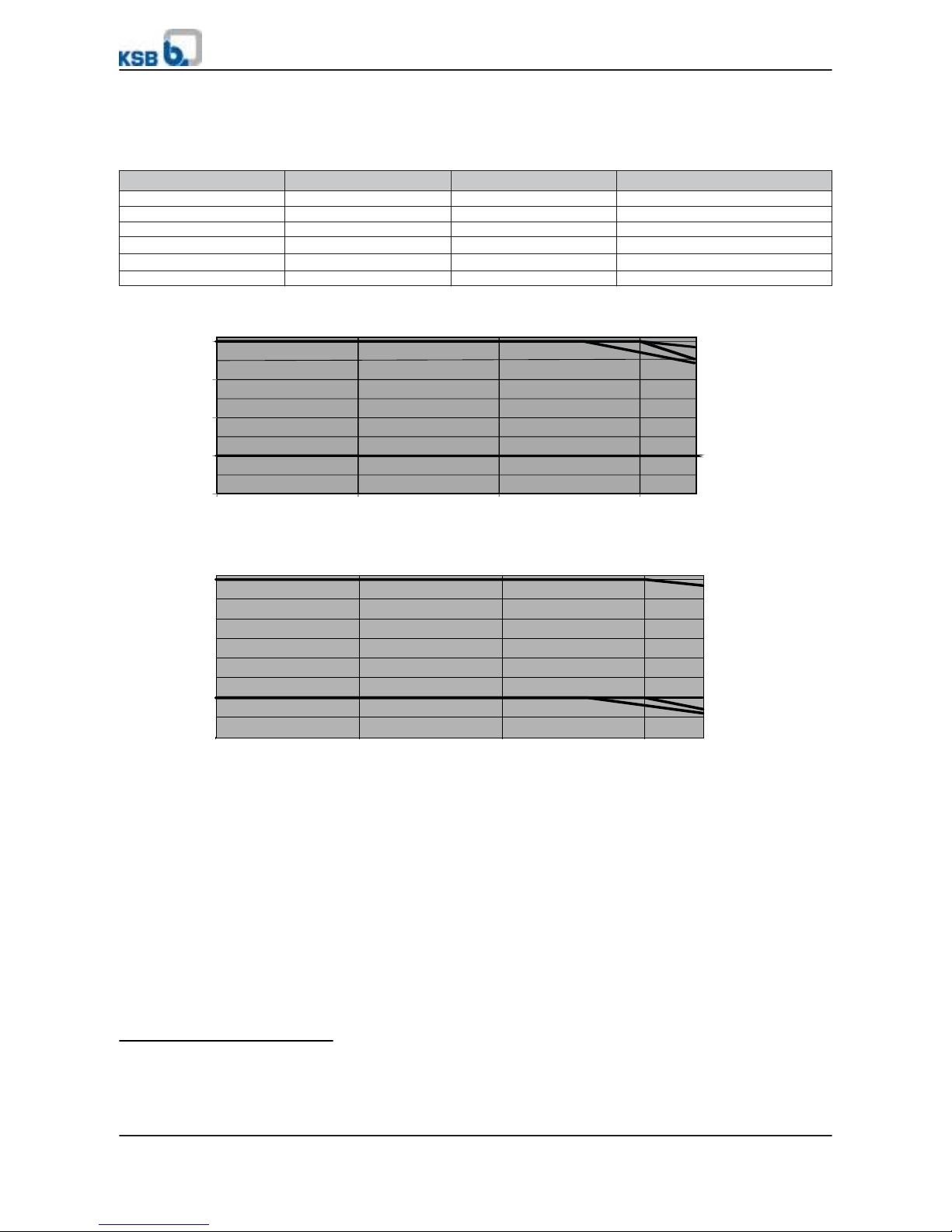

Overview of acceptance tests/warranty

Acceptance tests/warranty Region

Materials testing

▪Test report 2.2 on request A, B, C

Final inspection

▪Inspection certificate 3.1 to EN 10204 on request A, B, C

Hydraulic test against surcharge

▪The operating point of each pump with a delivery address or final destination in Europe is

warranted in accordance with ISO 9906/2B.

A

▪The operating point of each pump with a delivery address or final destination outside of

Europe is warranted in accordance with ISO 9906/2B and ISO 9906/3B.

B, C

▪NPSH test A, B, C

Other inspections/tests possible on request A, B, C

Warranty

▪Warranties are given within the scope of the valid delivery conditions. A, B, C

Centrifugal Pumps with Shaft Seal

Standardised Water Pumps

6Etanorm