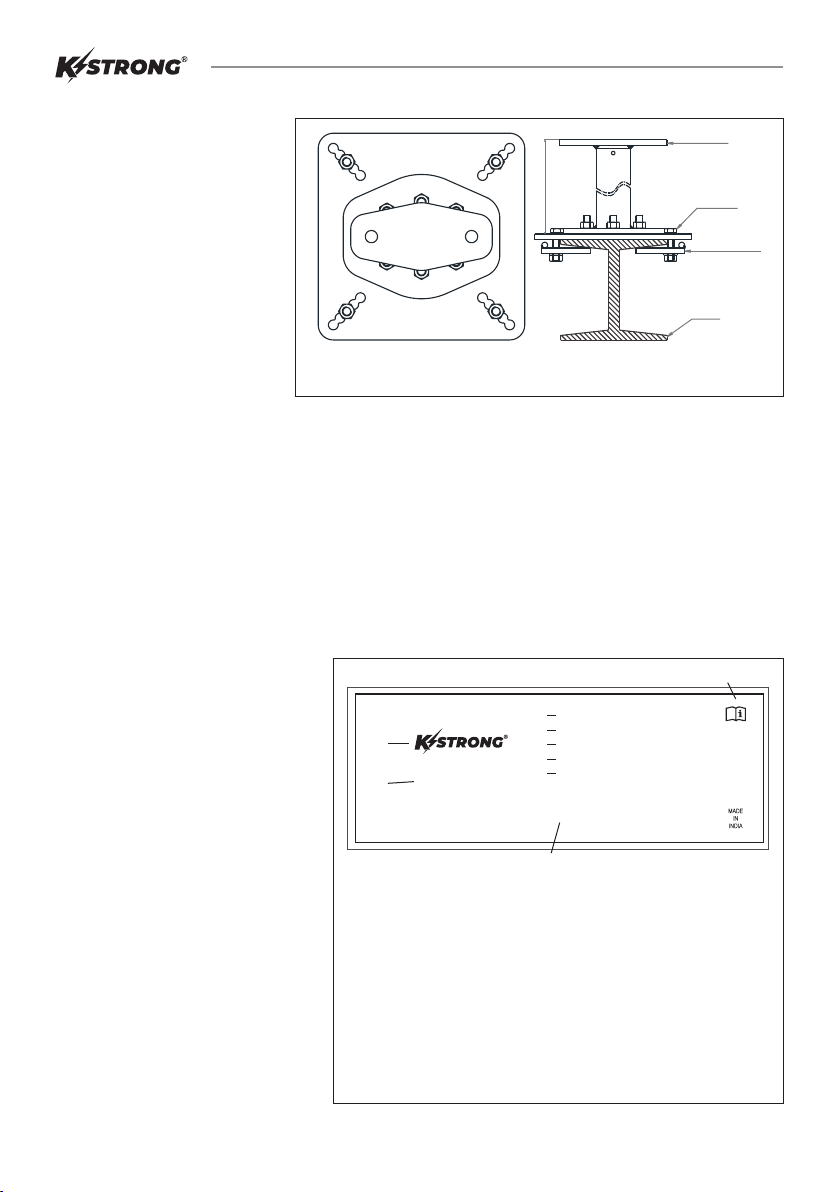

7. INSTRUCTIONS FOR USE:

AFA935831(SS)

ŸInstall the Anchor on the metal I

beam with help of provided

fastners.

ŸConnect the Universal Extremity

Plate or intermediate for making

connections.

ŸNow the Anchor is ready to Use.

8. ANCHORAGE STRENGTH : Ensure

that the structure on to which the

anchor is fitted is strong enough to with

stand a load of 20 kN. If unsure, please

refer to an engineer.

9. COMPATIBILITY: To optimise

protection, in some instance it may be

necessary to use the steel anchor with

suitable ppe such as

boots/gloves/helmet/ear defenders. In this case, before carrying out the risk-related activity, consult your supplier to ensure that all your

protective products are compatible and suitable for your application.

10. LIMITATIONS :

ŸIt should be the personal property of it's user.

ŸIt should not be used in highly acid or basic environment.

ŸIt is essential for the safety of user that if the product is resold outside the original country of destination, the reseller shall provide

instruction for use, maintenance, for periodic examination and for repair in the language of the country in which product is to be

used.

11. REPAIR: If the product becomes damaged, it will NOT provide the optimum level of protection, and therefore should be immediately

removed from service. Never use the damaged product. Repair is permitted, provided that it is either done by the manufacturer or a

competent repair centre or individual approved by the manufacturer.

12. WITHDRAWAL FROM USE: If the system has been used to arrest a fall, it should be removed from service and returned to the

manufacturer or a competent repair centre for

servicing and re test.

13. CLEANING & MAINTENANCE: In case of

minor soiling, wipe the anchor with cotton cloth

or a soft brush. Do not use any abrasive

material. For intensive cleaning wash the

anchor in water at a temperature between

30°C to 60°C by using a neutral detergent

(pH+ 7). The washing temperature should not

exceed 60°C. Do not use acid or basic

detergents.

14. STORAGE AND TRANSPORT : When not in

use, store the anchor away from heavily acidic

or basic environment. Never place heavy

items on top of it. Also ensure that it is stored

away from chemically hazardous environment

preferebly storage should be in dry

environment.

15. WARNING: Do not make any alteration or

additions to the equipment without the

manufacturer's prior written consent and repair

shall only be carried out by personnel trained

by the manufacturer & duly authorized by him.

AFA935831(SS)

(Where XX Is Length of Anchor Post)

Anchor Post

Fastener

Anchor Base

Plate

I Beam

XX

02

MARKING EXPLANATION

The Anchor is marked with :

(I)

(ii) Product Type

(iii) Ref. No.

(iv) UID

(v) Manufacturing Date

(vi) Rated Load

(vii) Read the user instructions before use.

(viii) Manufacturer’s address

(ix) Norm Reference.

Identification of the manufacturer.

MARKING ( )vii

(ix)

(ii)

(iii)

(iv)

(v)

(vi)

(viii) 150 N. Radnor Chester

Road Suite F200 Radnor,

Pennsylvania 19087 United States EN 795:2012 Type A

Product : Anchor Post

Ref. no : AFA935831(SS)

UID. : XXXXXXXXXXXXX

Date of Mfg : XXXX

Rated load : 100kg

Read the user

instructions

carefully

before each

use.

(i)