SA 33

3. ADVICE & INFORMATION:

ŸIt should be the personnel property of it's user.

ŸIt should not be used in highly acid or basic environments.

ŸThe anchor has been tested to EN 795:2012 Type E and is appropriate only for single person use with an energy

absorber as per EN 355:2002 that is rated to user mass up to 140kg.

ŸEnsure that the structure on to which the anchor is tted is strong enough to with stand a load of 20 kN.

ŸEnsure that the equipment is compatible with other items when assembled into a system.

ŸIt is essential to verify the free space required beneath the user at work place before each occasion of use so that in

case of a fall there will be no collision with ground or other obstacle in the fall path.

ŸIt is essential for the safety of user that if the product is resold outside the original country of destination, the reseller

shall provide instruction for use, maintenance, for periodic examination and for repair in the language of the

country in which product in to be used.

ŸAnchor device should be marked with the date of the next or last inspection done.

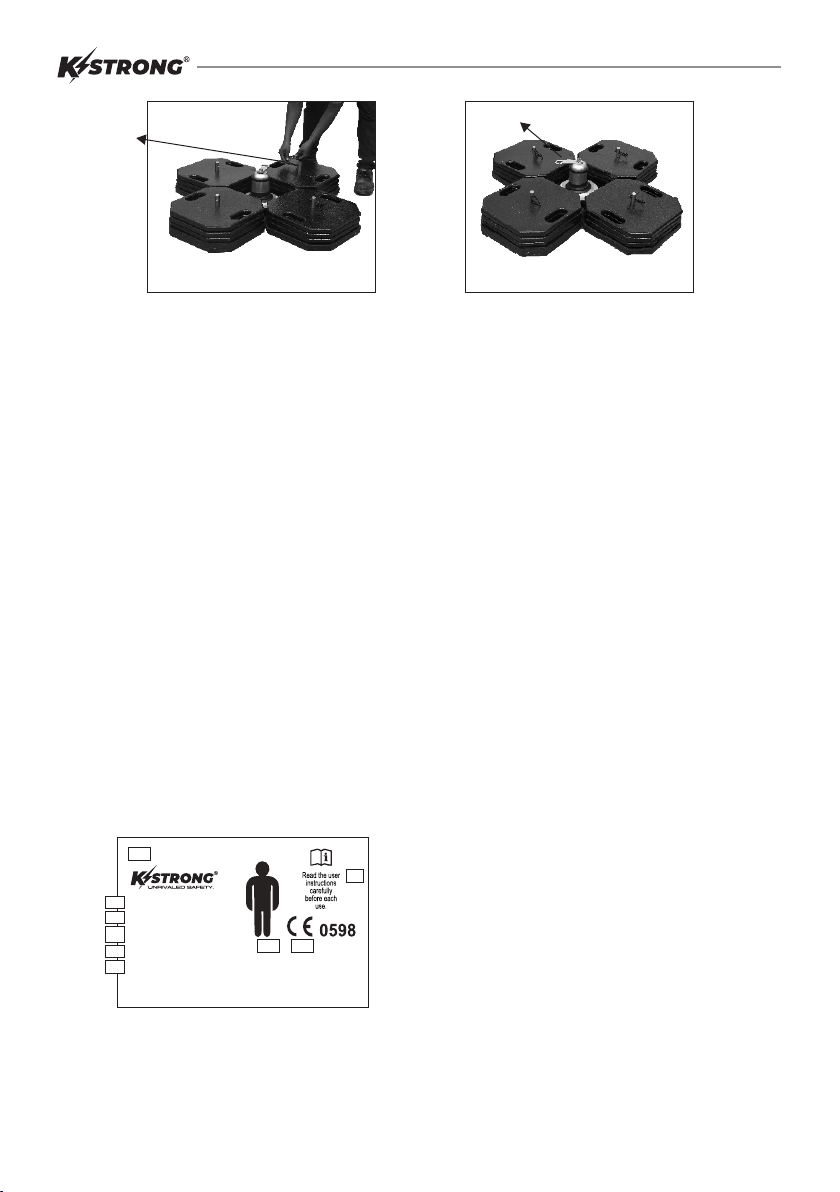

ŸDead weight Bottom plate is made up of TPV material which is metallic reinforced.

ŸAnchor device should be positioned and the work carried out in such a way as to minimize both the potential for

falls and potential fall distance.

ŸA full-body harness is the only acceptable body holding device that can be used in a fall arrest system.

ŸWhen the equipment becomes wet, either from being in use or when due to cleaning, it should be allowed to dry by

itself and be kept away from open re or any other source of heat.

ŸStandard packaging supplied from the manufacturer should be used during transportation to protect the

equipment against damage.

ŸIt is necessary for the user to carry out a pre-use check of equipment, to ensure that it is in a serviceable condition

and operates correctly before it is used.

ŸIt is important to conduct a regular periodic examination of the product because the safety of the user depends

upon the continued efciency and durability of the product.

ŸPeriodic examination frequency shall be at least every 12 months.

ŸPeriodic examinations are only to be conducted by a competent person strictly in accordance with the

manufacturer's periodic examination procedure.

ŸEnsure that all markings on the product are legible and can be clearly read.

4. WARNING:

ŸEnsure the Medical condition of the user does not affect his safety in normal and emergency use.

ŸThe equipment shall only be used by a person trained and competent in its safe use.

ŸA rescue plan shall be in place to deal with any emergencies that could arise during the work.

ŸDo not make any alteration or additions to the equipment without the manufacturer’s prior written consent and

repair shall only be carried out by personnel trained by the manufacture & duly authorized by him.

ŸThe equipment shall not be used out side its limitation, or for any purpose other than that for which it is intended.

ŸThe Anchor device should not be positioned in areas where water could accumulate and create a hazard.

ŸThe Anchor device should not be used when there is a risk of frost, or in freezing conditions where frost or freezing

conditions create a hazard.

ŸThe Maximum angle from the horizontal surface permitted for the anchor device is 5 degrees.

ŸThe device should not be used where there is Oil, grease or algae on the surface.

ŸThe Anchor device can be used on Concrete, Bitumin & Asphalt roofs.

ŸThe Anchor device should not be used in combination with retractable type fall arresters unless they have been

tested together.

ŸWhen anchor devices are combined with energy-absorbing lanyards(EN 355) that have not been tested together

may cause Major injury or even death.

ŸWhere the users intend to combine any personal fall protection equipment for fall arrester with an anchor device,

they should seek guidance on its suitability from the manufacturer before doing so.

02