Remove page (s) Replace by page (s) Insert page (s) after page

2-13 2-13F

4-8 4-8F

5-7 5-7F

5-16 5-16F

5-23 5-23F

6-6 6-6F

6-8 to 6-9 6-8F to 6-9F

6-15 6-15F

6-19 6-19F

10-1 10-1F

10-3 10-3F

10-5 to 10-7 10-5F to 10-7F

10-9F 10-8

11-2 11-2F to 11-2Fb

11-67 to 11-69 11-67F to 11-77F

12-1Fb 12-1

12-38F to 12-47F 12-37

13-2F to 13-2Fd 13-1

13-63 to 13-64 13-63F to 13-134F

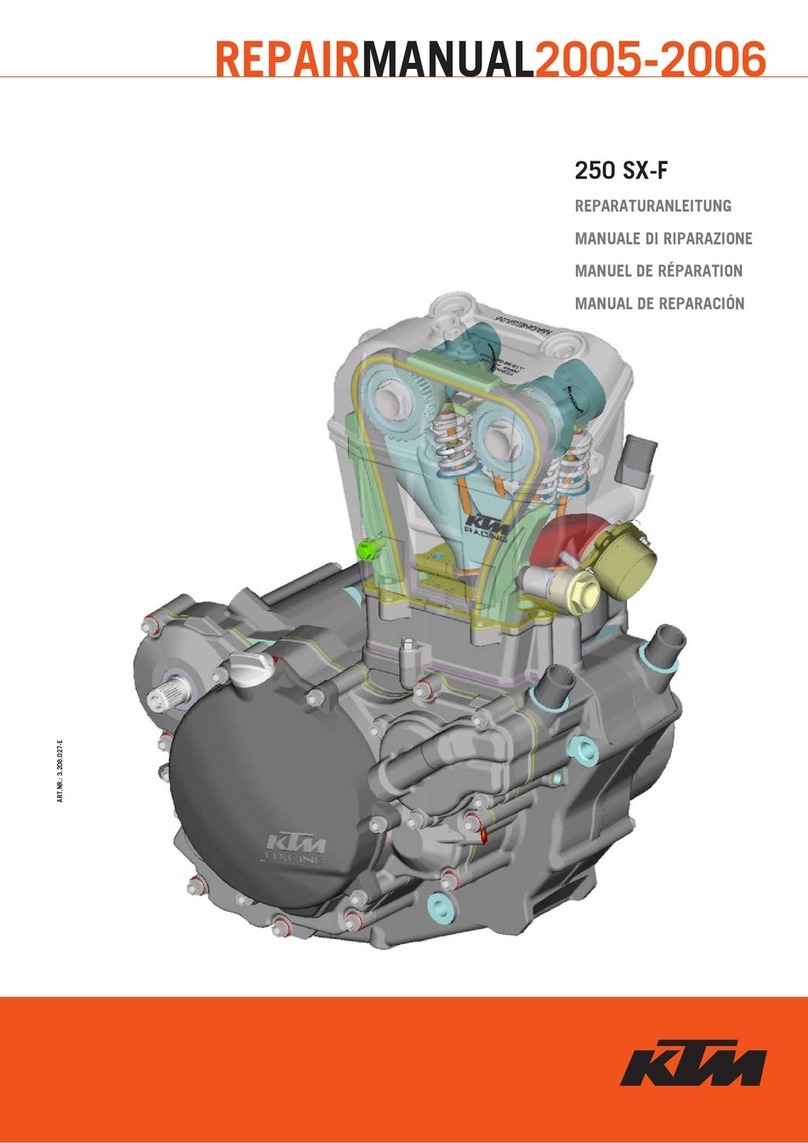

IMPORTANT INFORMATION/UPDATING INSTRUCTIONS

To be able to continue using the existing loose-leaf repair instructions, simply print the

following pages and insert them in the existing repair instructions:

1,3,7,9,28,49,65,74,81,93,95,96,102,106,225,228,230-232,234,237,238,

303-313,316,354-363,366-369,430-501

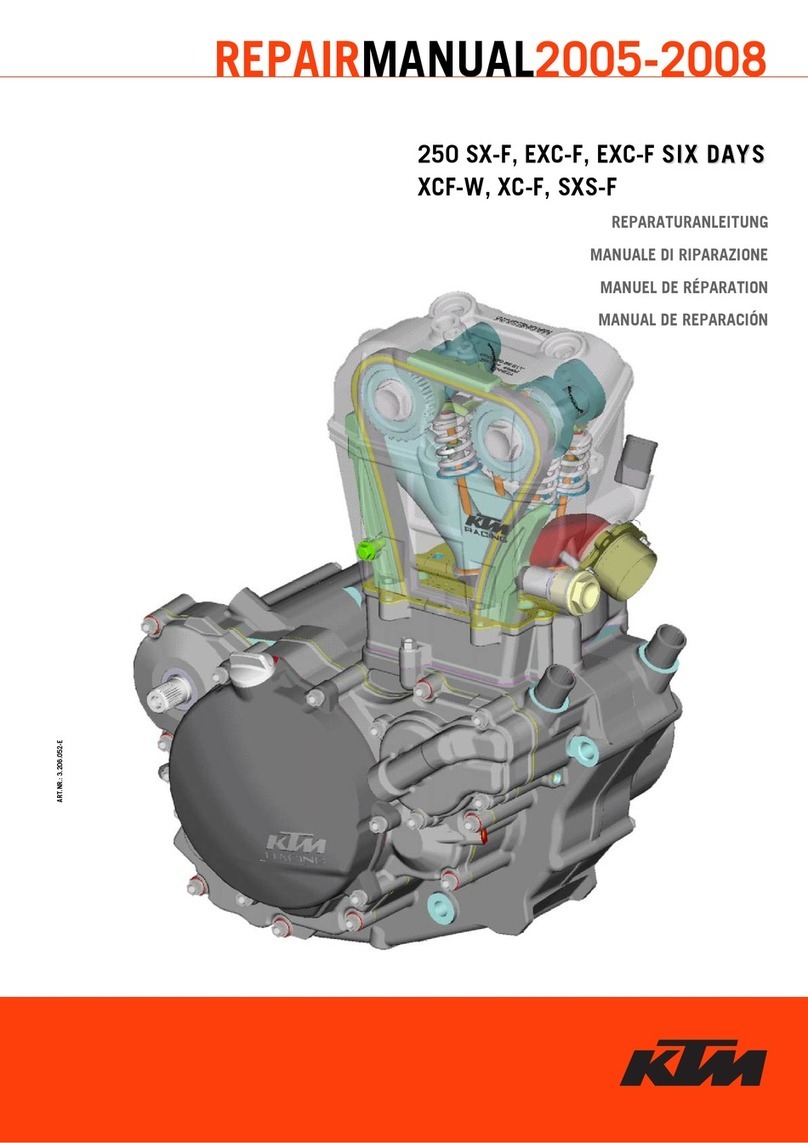

KTM REPAIR MANUAL IN LOOSE-LEAF FORM

STORING THE REPAIR MANUAL IN THE BINDER

– Put the index into the binder.

– Put the front page of the repair manual (210x297 mm) into the transparent pocket provided for this purpose on the outside of

the binder.

– Put the spine label (170x45 mm) into the transparent pocket provided for this purpose on the spine of the binder.

– Put the summary list of contents (150x297 mm) into the transparent pocket provided for this purpose on the inside of the

binder or insert this page on the beginning of the manual.

– Then insert the individual chapters of the manual between the sheets of the index according to the page number printed in

the right bottom corner of each page.

Example: page no. 3-5; 3 = chapter 3; 5 = page 5

All pages with a page number that begins with the digit 3, for example, must be put under the index heading „Chapter 3“.

– Index sheets that have not been marked with a certain chapter are for your personal convenience. The respective headings can

be entered in the list of contents.