Initial

11

2

13 10 4

9

57

2

OFF

ON

8

6

3

12

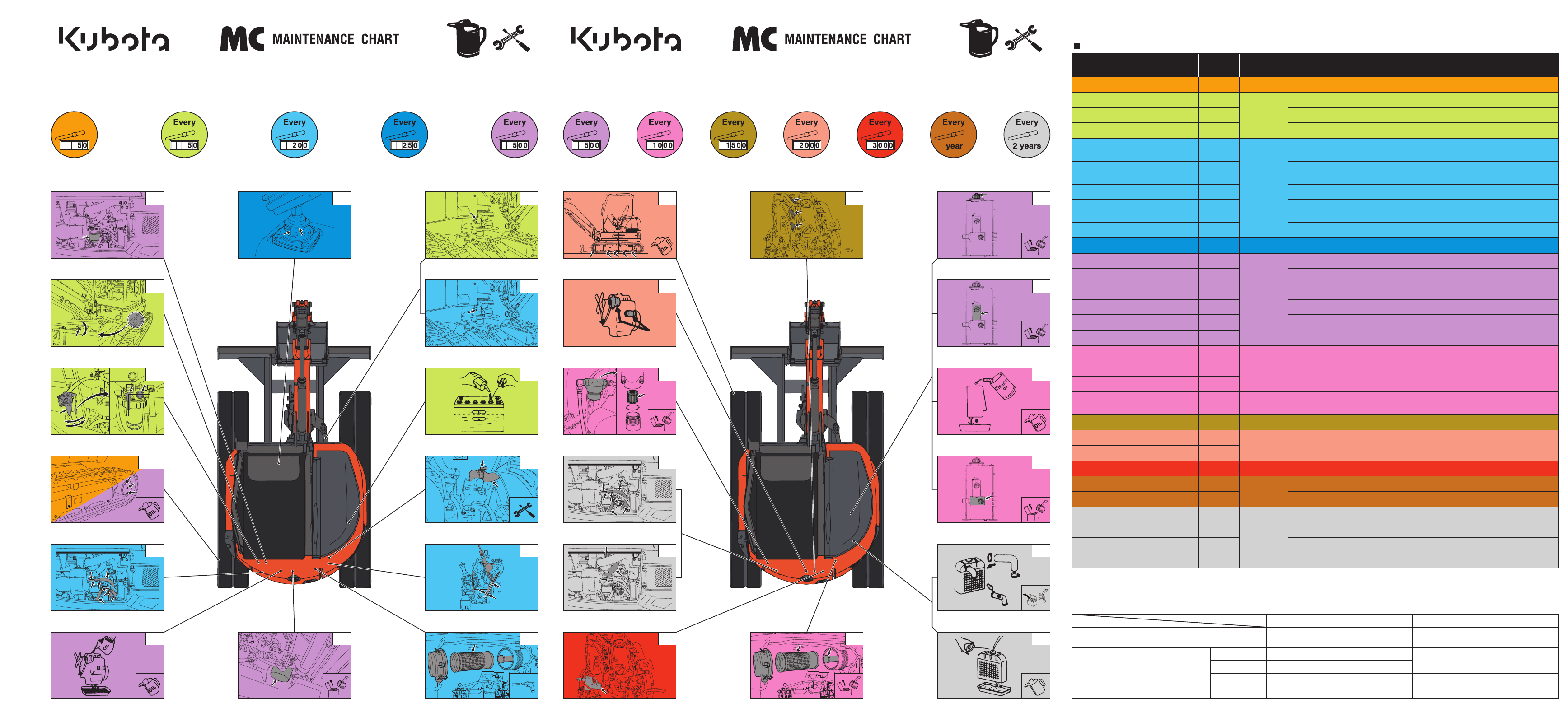

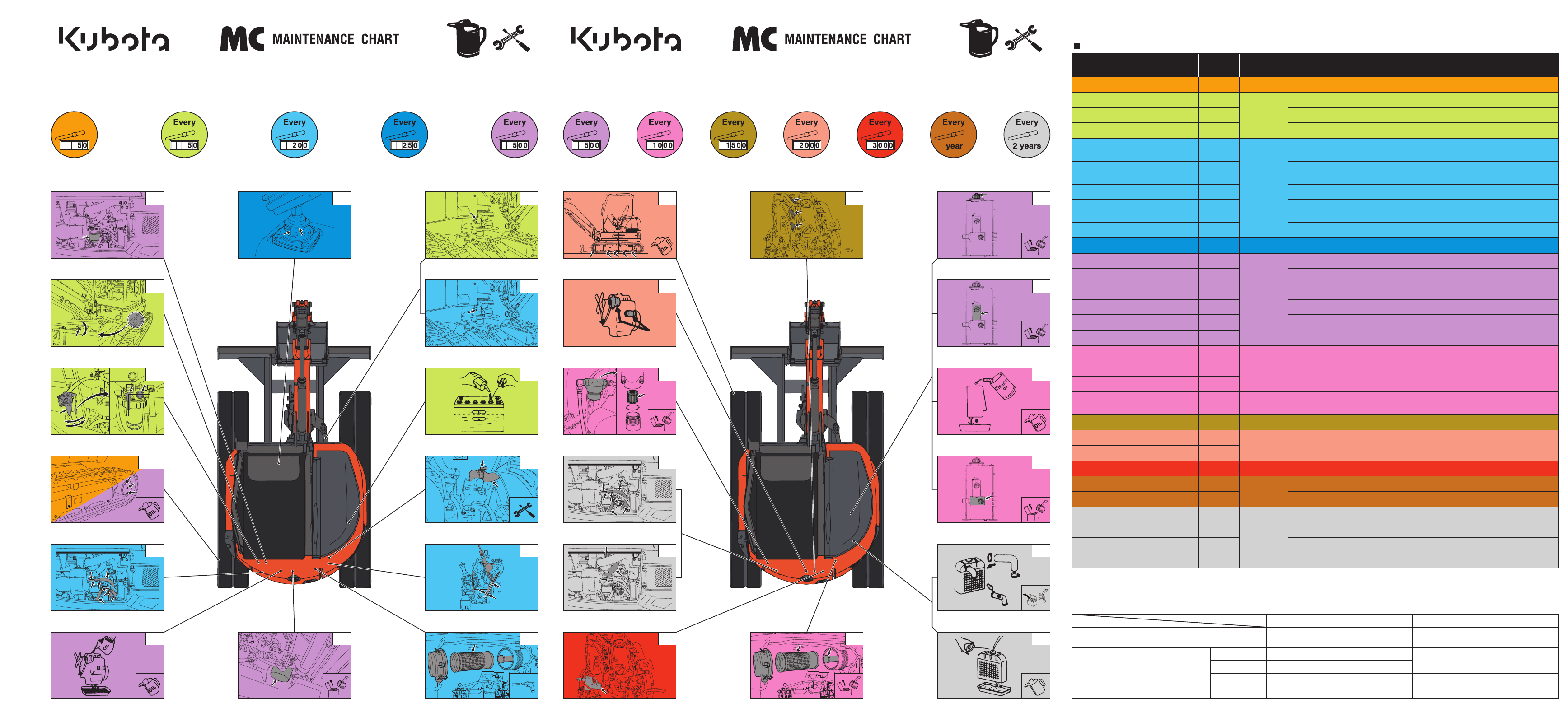

U27-4 EXCAVATOR (NA VERSION)

1,14

18

23

28

27

29

30

16

17

20

19

1522 21

24

U27-4 EXCAVATOR (NA VERSION)

Item Contents Interval NoteNo.

Drive unit oil Change Initial 50 hrs

1Initial oil change.

Fuel tank, water separator Drain

2Drain water from the tank and water separator.

Battery condition Check 50 hrs

3Check the battery conditions with the indicator.

Greasing swing bearing teeth Grease

4Replenish grease to the grease nipple by a grease gun.

Fan belt tension Adjust

200 hrs

5Press the fan belt down in the middle, with a force of approx. 7 kg (15.41 lbs).

The belt tension is correct if it deflects about 7 mm (0.28 in.).

Radiator hoses and clamps Check

6This check should be done every 200 hours or every 6 months, whichever comes

first.

Fuel line and Intake air line Check

7Clean the outer element. Do not remove the inner-element.

Air filter element (outer element)

(*1) Clean

8The element should be cleaned more frequently if the machine is used in extremely

dusty areas.

Greasing swing ball bearing Grease

9Replenish grease to the grease nipple by a grease gun.

Lubrication of the pilot valve Grease 250 hrs

10 Grease the tip of the push rod and the rotating part of the link.

Engine oil Change

500 hrs

11 Regardless of the service hours, an engine oil change is due every 1 year.

Engine oil filter cartridge Replace

12 Always check the oil level when replacing the filter.

Fuel filter cartridge Replace

13 The fuel system must be purged of air after the replacement.

Drive unit oil Change

14 Change drive unit oil every 500 hrs or at least once a year.

Breather filter Replace

15 Always check the oil level when replacing the filter.

Hydraulic return filter element (*2) Replace

16

Hydraulic pilot filter element Replace

1000 hrs

17 O-ring can’t be reused.

Hydraulic oil (*2) Change

18 Before these maintenance, stop the machine on flat ground and lower the bucket

to the ground.

Hydraulic suction filter element Replace

19

Air filter element (inner and

outer element) Replace 1000 hrs or

once a year

20 Shorten the replacement period if the machine is used in dusty or sandy areas.

Fuel injection nozzle Check 1500 hrs

21 Consult your local KUBOTA dealer for this service.

Front idler and track roller oil Change

2000 hrs

22 Contact your KUBOTA dealer for details.

Alternator and starter motor Check

23

Injection pump Check 3000 hrs

24 Consult your local KUBOTA dealer for this service.

Electrical wiring and fuses Check

Every year

25 Check the terminals for proper connections.

Electrical circuit Check

26 Check the electrical circuitry for disconnections, shorts or loose terminals.

Radiator hoses and hose clamps Replace

Every 2 years

27 Replace radiator hoses and hose clamps every two years.

Radiator coolant Change

28 In case of long life coolant.

Fuel hoses and hose clamps Replace

29 Replace the hoses and clamps.

Intake air line Replace

30 Replace the hoses and clamps, if necessary.

Normal excavator work

Hammer work portion

20%

40%

60%

More than 80%

(*2) When using a hydraulic breaker, the interval of changing hydraulic oil becomes short as follow.

(*1) Clean and replace the air filter more frequently if used under dusty conditions. When the filter is very dirty from dusty conditions,

replace the filter.

Hydraulic oil

Every 1000 hrs

Every 800 hrs

Every 400 hrs

Every 300 hrs

Every 200 hrs

Every 500 hrs

(250 hrs after first operation)

Every 200 hrs

Every 100 hrs

Hydraulic return filter element

REGULAR MAINTENANCE