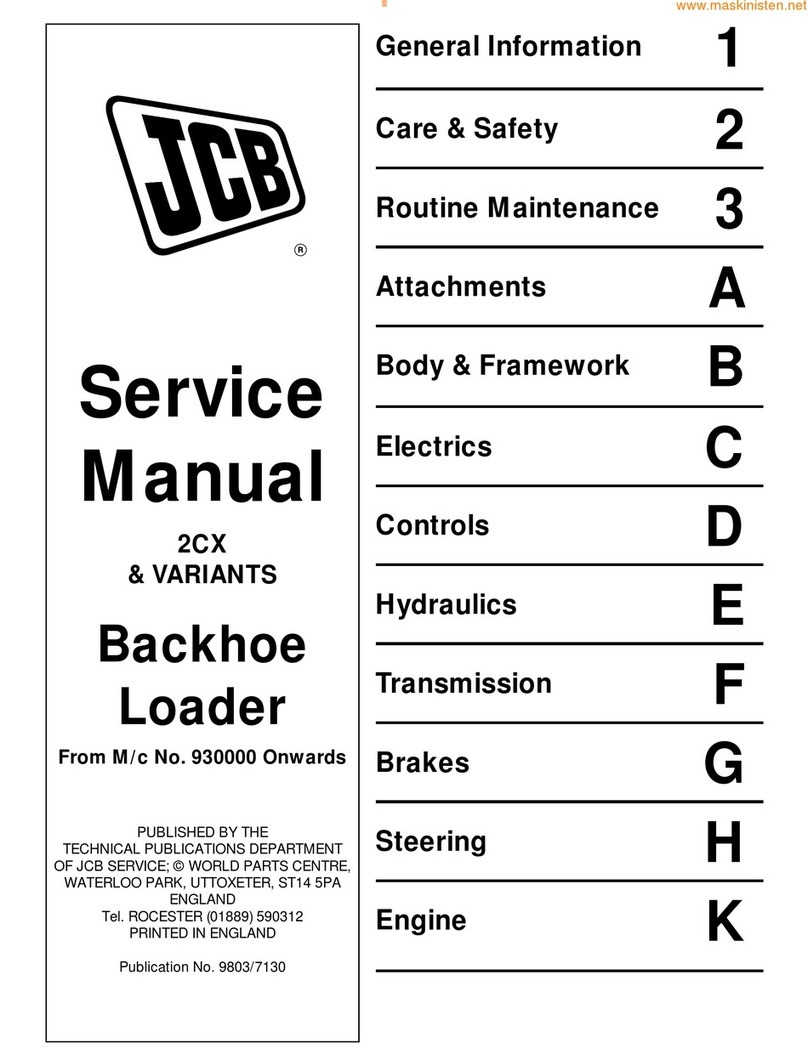

SAFE OPERATION2

1. Operate the loader only when properly seated at the

controls. Do not operate from the ground.

2. Move and turn the tractor at low speeds.

3. Never allow anyone to get under the loader bucket or

reach through the boom when the bucket is raised.

4. Keep children, others and livestock away when

operating loader and tractor.

5. Do not walk or work under a raised loader bucket or

attachment unless it is securely blocked and held in

position.

6. For tractor stability and operator safety, rear ballast

must be added to the 3-point hitch and to the rear

wheels when using loader.

7. To increase stability adjust the rear wheels to the

widest setting that is suitable for your application.

8. Exercise extra caution when operating the loader with

a raised bucket or attachment.

9. Do not lift or carry any person on the loader, in the

bucket, or other attachment.

10.Avoid loose fill, rocks and holes. They can be

dangerous for loader operation or movement.

11.Avoid overhead wires and obstacles when the loader

is raised. Contacting electric lines can cause

electrocution.

12.Gradually stop the loader boom when lowering or

lifting.

13.Use caution when handling loose or shiftable loads.

14.Using loaders for handling large, heavy, or shiftable

objects is not recommended without proper handling

attachments.

15.Handling large heavy objects can be extremely

dangerous due to :

ADanger of rolling the tractor over.

ADanger of upending the tractor.

ADanger of the object rolling or sliding down the

loader boom onto the operator.

16.If you must perform this sort of work (item 15), protect

yourself by :

ANever lift the load higher than necessary to clear

the ground.

AAdd rear ballast to the tractor to compensate for the

load or use rear implement.

ANever lift large objects with equipment that may

permit them to roll back onto the operator.

AMove slowly and carefully, avoiding rough terrain.

17.Never lift or pull a load from any point on the loader

with a chain, rope, or cable. Doing so could cause a

rollover or serious damage to the loader.

18.Be extra careful when operating the tractor on a slope,

always operate up and down, never across the slope.

Do not operate on steep slopes or unstable surfaces.

19.When operating another implement on a hillside, be

sure to remove the loader to reduce the risk of rollover.

20.Carry loader boom at a low position during transport.

(You should be able to see over the bucket.)

21.Allow for the loader length when making turns.

1. When loader work is complete and parking or storing,

choose flat and hard ground. Lower the loader boom

to the ground, stop the engine, set the brakes and

remove the key before leaving the tractor seat.

2. Make sure the detached loader is on stands and on a

hard, level surface.

3. Before disconnecting hydraulic lines, relieve all

hydraulic pressure by moving the controls.

4. Do not remove the loader from the tractor without an

approved bucket attached.

1. Always wear safety goggles when servicing or

repairing the machine.

2. Do not modify the loader. Unauthorized modification

may affect the function of the loader, which may result

in personal injury.

3. Do not use the loader as a work platform or a jack to

support the tractor for servicing or maintenance.

Securely support the tractor or any machine elements

with stands or suitable blocking before working

underneath.

For your safety, do not work under any hydraulically

supported devices. They can settle or suddenly leak

down or be accidentally lowered.

4. Escaping hydraulic oil under pressure can have

sufficient force to penetrate the skin, causing serious

personal injury. Do not use hands to search for

suspected leaks. If injured by escaping fluid, obtain

medical treatment immediately.

5. Do not tamper with the relief valve setting. The relief

valve is pre-set at the factory. Changing the setting

can cause overloading of the loader and tractor which

may result in serious personal injury.

6. When servicing or replacing pins in cylinder ends,

bucket, etc., always use a brass drift and hammer.

Failure to do so could result in injury from flying metal

fragments.

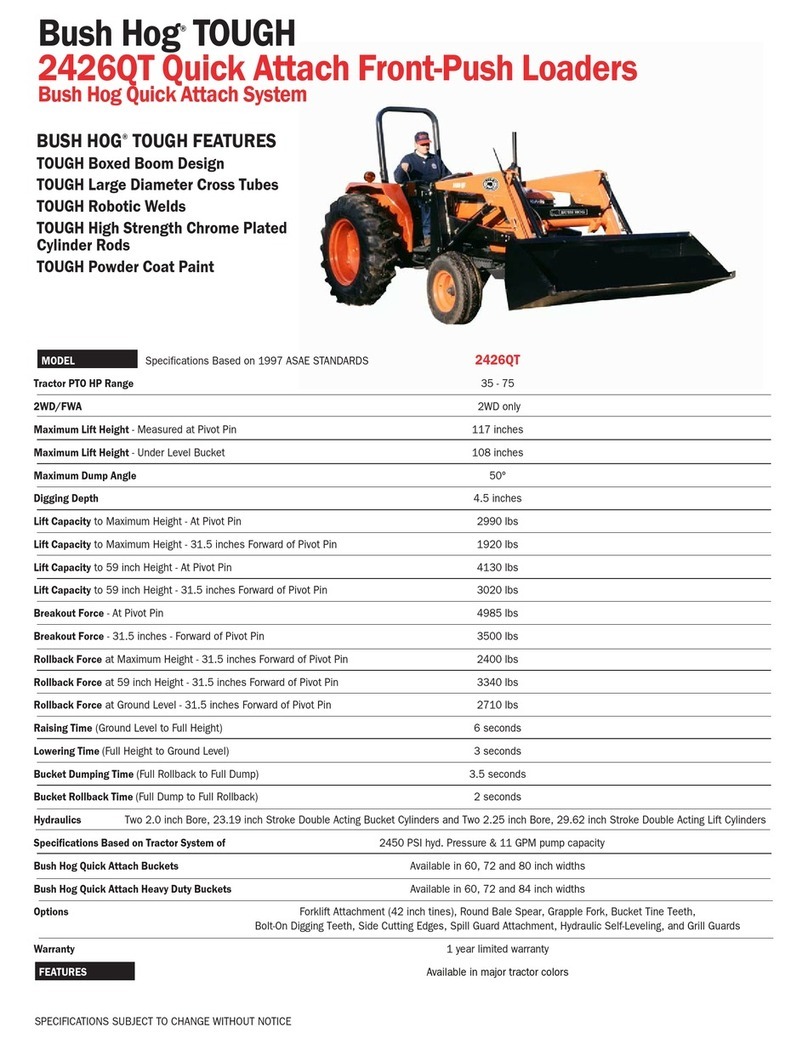

2. OPERATING THE LOADER

3. AFTER OPERATING THE LOADER

4. SERVICING THE LOADER