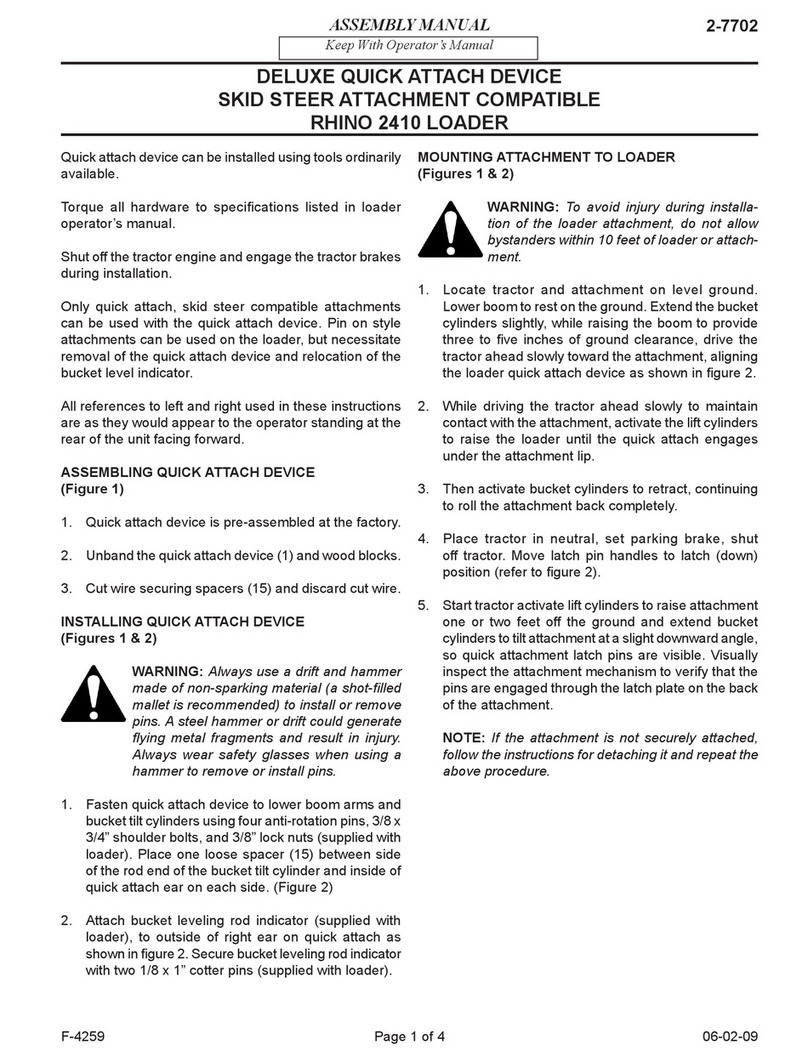

1ASSEMBLY INSTRUCTIONS

ASSEMBLY INSTRUCTIONS

TO THE DEALER

1. This manual contains procedures intended to assist

the dealer in unpacking and assembling the product

before delivering to the customer.

The customer's purchase is based on confidence in

both the product and your store. Observe the

procedures in this manual to assemble and adjust

equipment for your customer's safety and satisfaction.

When fully assembled, check function of each part and

feature.

2. The following safety alert symbol marks and

indications are found throughout this manual in steps

where particular attention is required so as to ensure

your safety and to avoid product damage. Observe

the instructions in these warnings where indicated.

SAFETY

To prevent accidents, read through the following items

before starting work, and always regard safety when

working. It is your responsibility to ensure your safety on

the job.

1. Preparations

(1) Select a work site which is level, has sufficient

space, and is not close to dangerous objects.

(2) Avoid poorly ventilated

rooms.

Asphyxiation from exhaust

fumes is always a possibility

that accompanies running an

engine.

(3) Working clothes which may

be pinched or caught in the

equipment must not be worn.

Loose clothing can cause

serious injury or death.

(4) Always wear a mask and

protective goggles during

work when dust or flying

debris may be thrown by

equipment.

2. Assembly and adjustments

(1) Before assembling

equipment, read the

assembly instructions for the

product to become familiar

with the equipment and

procedures.

(2) Use only adequate and

required equipment, tools

and instruments (e.g. torque

wrench, battery hydrometer

and etc.).

(3) Set the parking brake and

block wheels to prevent

machine (or tractor)

movement.

(4) Lower the attachment or

implement to the ground

before assembling or

adjusting equipment.

(5) Before working under

suspended or raised

equipment, support the

equipment or attachment

and utilize the valve lock to

prevent the machine from

falling or moving out of place.

(6) Keep fire from cigarettes,

matches or other ignition

sources away from fuel, oil,

antifreeze and other

flammable materials.

Indicates an imminently

hazardous situation which, if not

avoided, will result in death or

serious injury.

Indicates a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

Indicates a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

Indicates that equipment or

property damage could result if

instructions are not followed.

Gives helpful information