214809

1

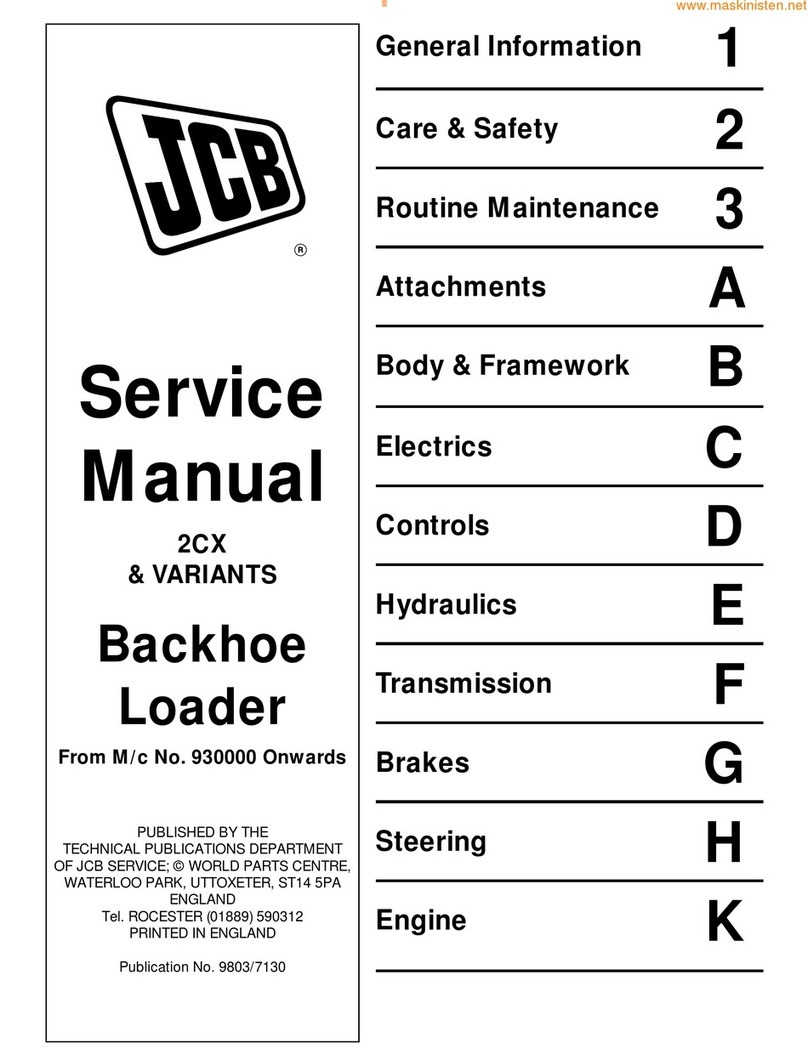

TABLE OF CONTENTS

1. INTRODUCTION...................................... 2

1.1. General information.................................................... 2

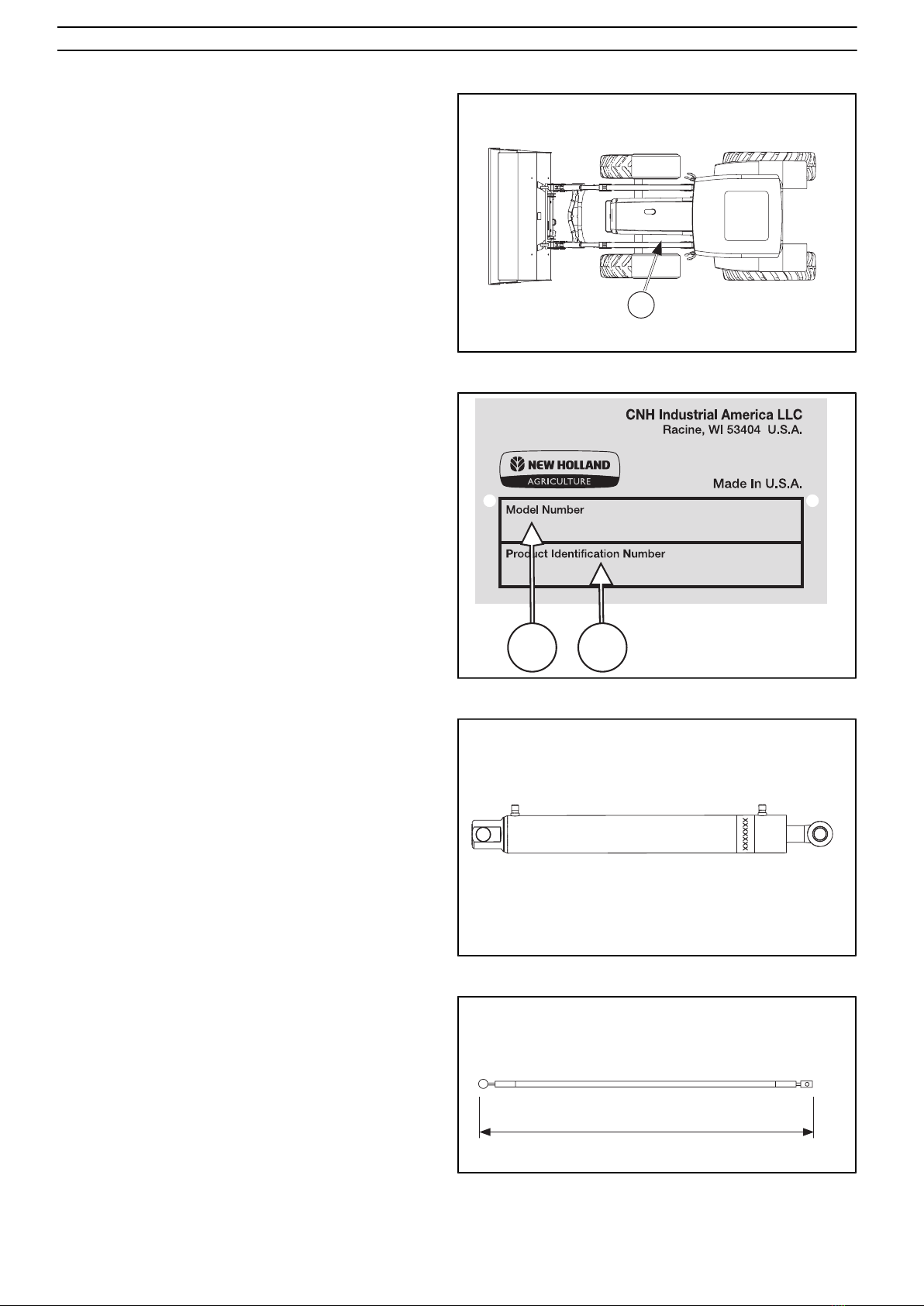

1.2. Identification................................................................3

1.2.1. Model and serial number........................................3

1.3. Alignment reference....................................................4

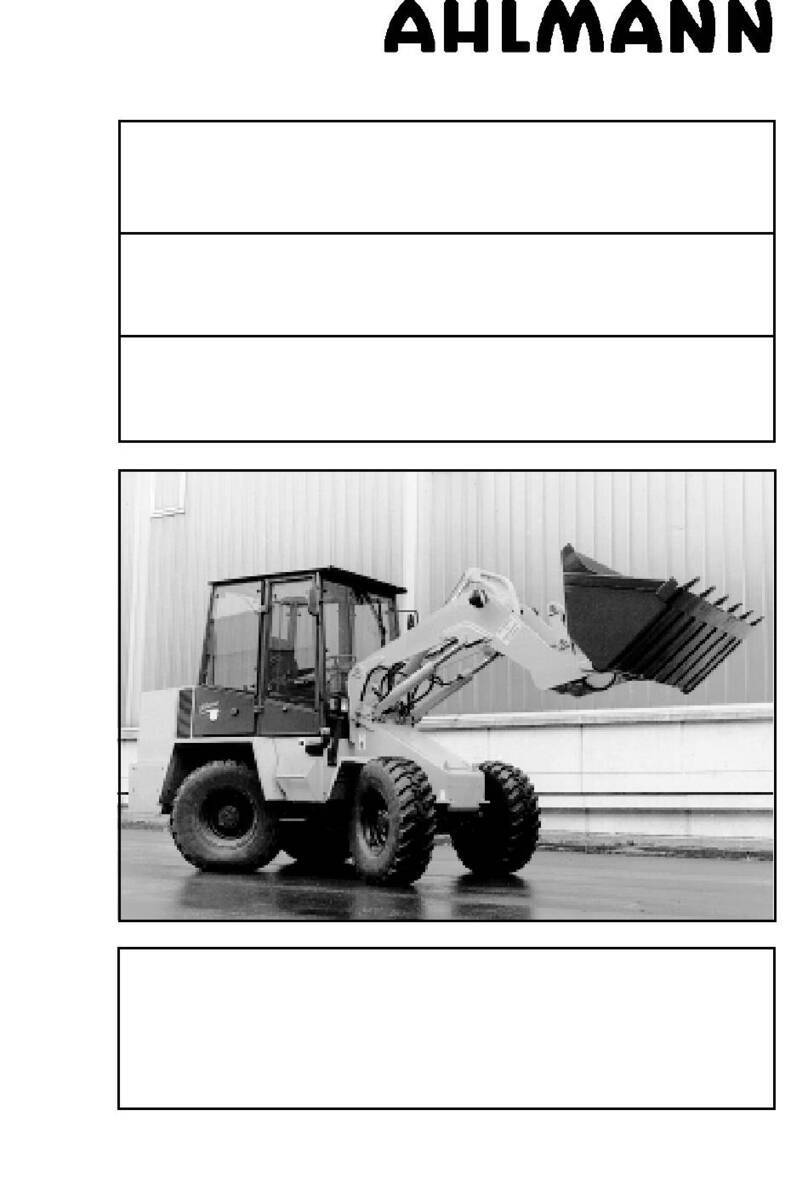

2. DESCRIPTION......................................... 5

2.1. Definitions................................................................... 5

2.1.1. Position indicator....................................................5

2.1.2. Control valve.......................................................... 5

2.1.3. Tool carrier............................................................. 5

2.1.4. Hose kit...................................................................5

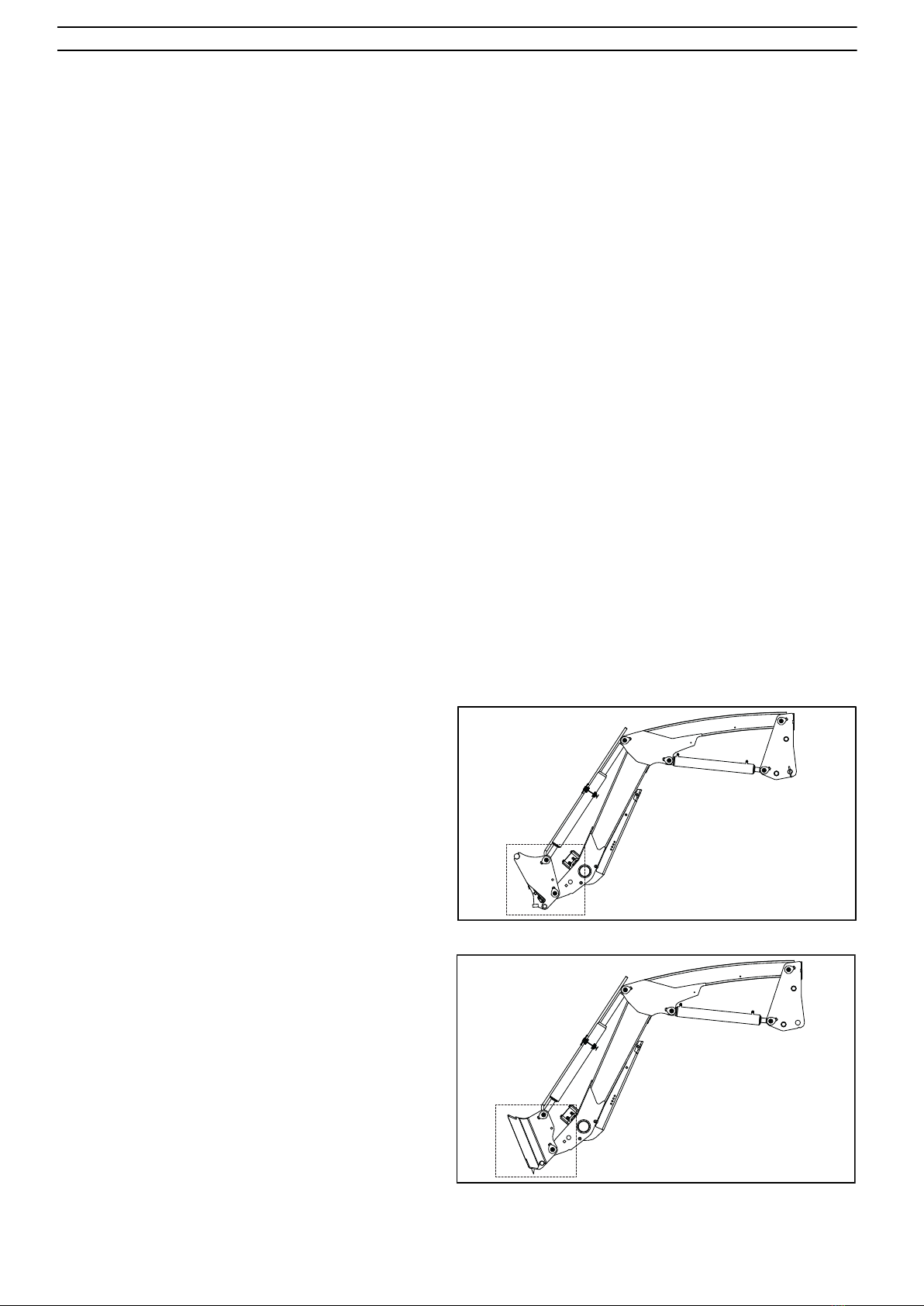

2.1.5. Loader with mechanical self-levelling....................5

2.1.6. Loader without mechanical self-levelling...............5

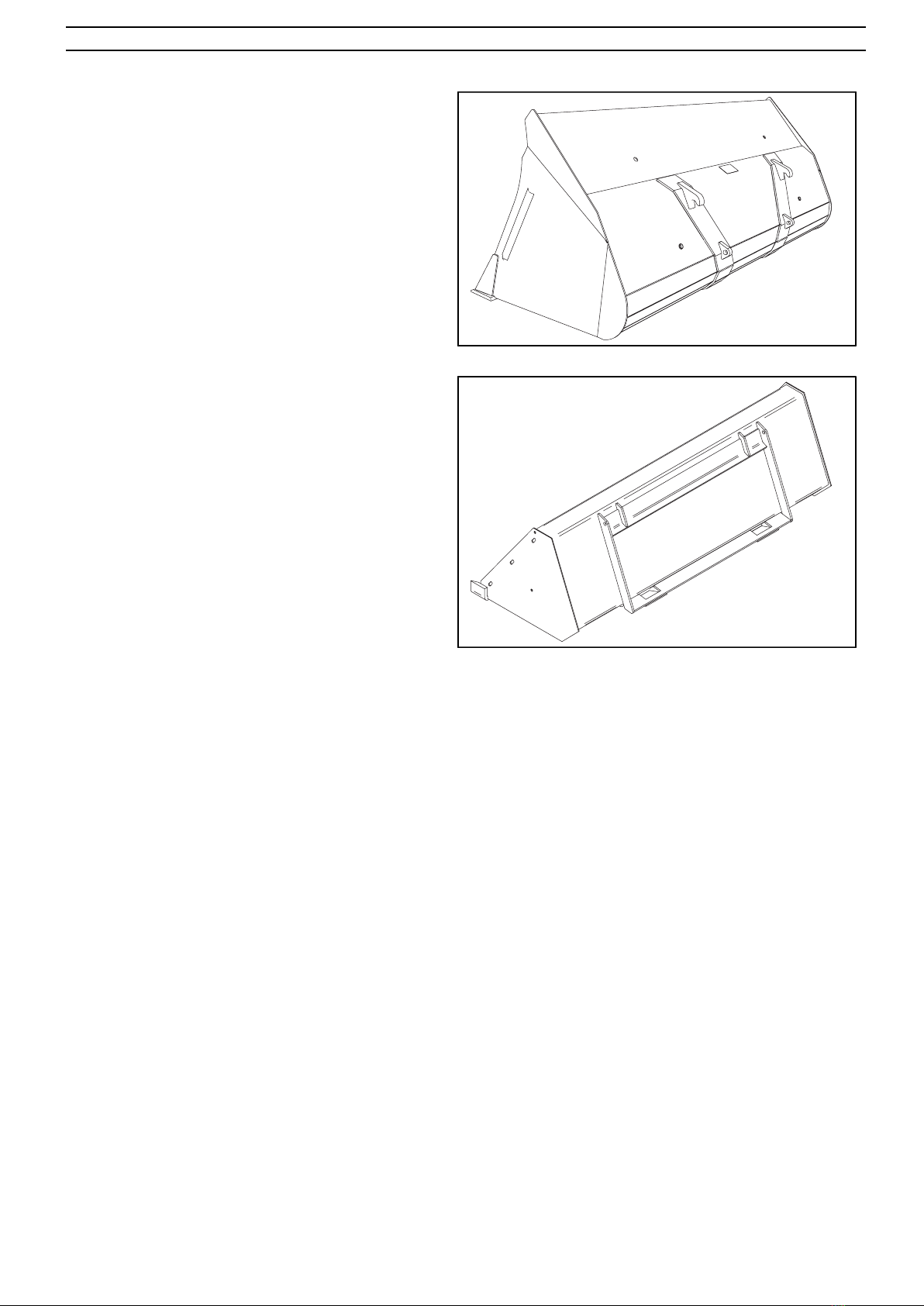

2.2. Tool carrier.................................................................. 5

3. SAFETY INSTRUCTIONS........................7

3.1. General information.................................................... 7

3.1.1. Guards.....................................................................7

3.1.2. Safety signs.............................................................7

3.2. Signal words................................................................7

3.3. Symbol explanation.....................................................8

3.3.1. Operator's manual...................................................9

3.4. Installing the loader.....................................................9

3.4.1. Joystick operation................................................... 9

3.5. Protection equipment.................................................10

3.5.1. Roll Over Protective Structure (ROPS)................10

3.5.2. Counterweight and tread width............................ 10

3.6. Before work...............................................................11

3.7. Operation................................................................... 11

3.7.1. Operator's position................................................11

3.7.2. Workplace............................................................. 12

3.7.3. Load stability........................................................ 14

3.7.4. Machine stability.................................................. 15

3.8. Risk factors during operation....................................16

3.8.1. During transport....................................................16

3.8.2. During service.......................................................17

3.8.3. Replacement parts.................................................17

3.9. Location of safety signs............................................ 18

4. INSTALLING THE LOADER..................19

4.1. Install the position indicator......................................20

4.2. Check list...................................................................20

5. OPERATION...........................................21

5.1. Tractor/Loader Stability............................................ 21

5.1.1. Determination of Ballast.......................................21

5.1.2. Minimum Tread Settings...................................... 21

5.1.3. Joystick operation................................................. 22

5.2. Connection and Operation Options...........................22

5.3. Disconnecting a loader..............................................22

5.4. Connecting a loader.................................................. 23

5.5. Loader Operation.......................................................25

5.5.1. Counterweight and tread width............................ 26

5.5.2. Checking attachment............................................ 26

5.5.3. Load stability........................................................ 27

5.5.3.1. Machine stability..............................................28

5.6. Operation with bale spike......................................... 29

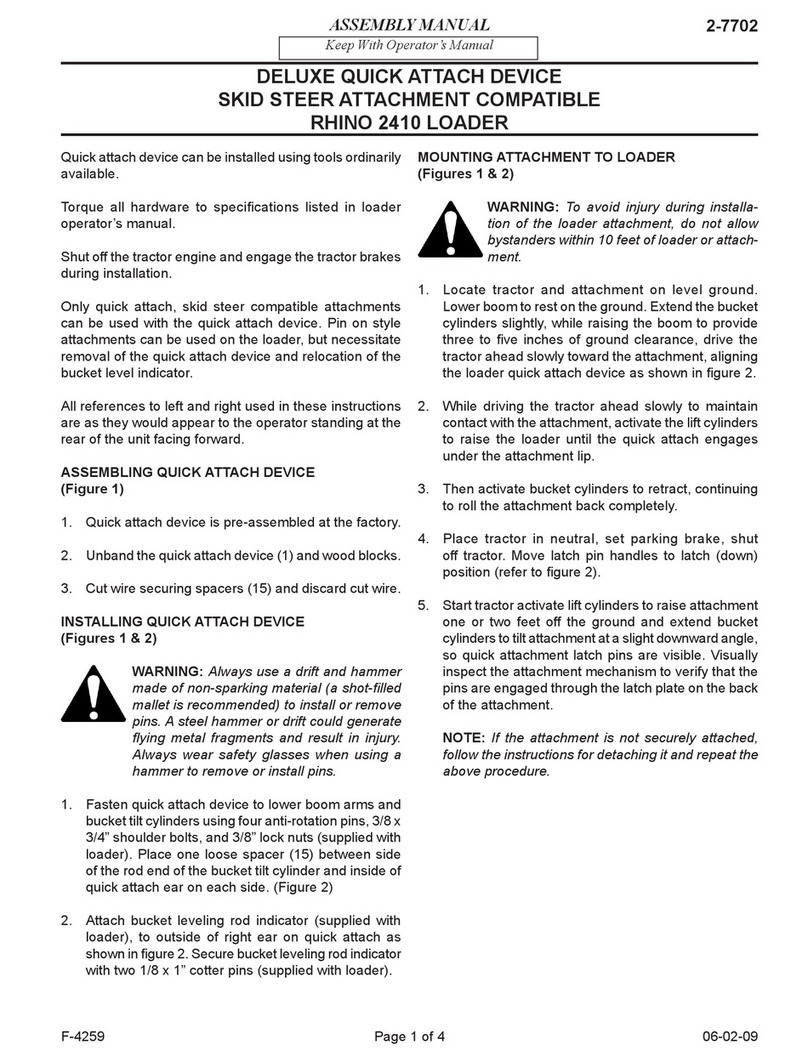

5.7. Coupling and uncoupling implements.......................30

5.7.1. Uncoupling implements, Euro 8 Tool carrier....... 30

5.7.2. Coupling implements, Euro 8 Tool carrier........... 31

5.7.3. Uncoupling Implements, Skid Steer Tool

carrier.............................................................................. 33

5.7.4. Coupling Implements, Skid Steer Tool

carrier.............................................................................. 33

6. MAINTENANCE..................................... 35

6.1. Lubrication.................................................................35

6.2. Hydraulic system.......................................................35

6.2.1. Hoses and cylinders..............................................35

6.2.2. Repair/replacement of hydraulic components...... 36

6.2.2.1. Hydraulic cylinders..........................................36

6.2.2.2. Hydraulic hoses................................................36

6.3. Checking the loader and subframe hardware............ 36

6.3.1. Torque................................................................... 36

6.3.1.1. Table - Torque..................................................37

6.4. Storage....................................................................... 37

6.5. Transporting the loader............................................. 37

7. TROUBLESHOOTING........................... 38

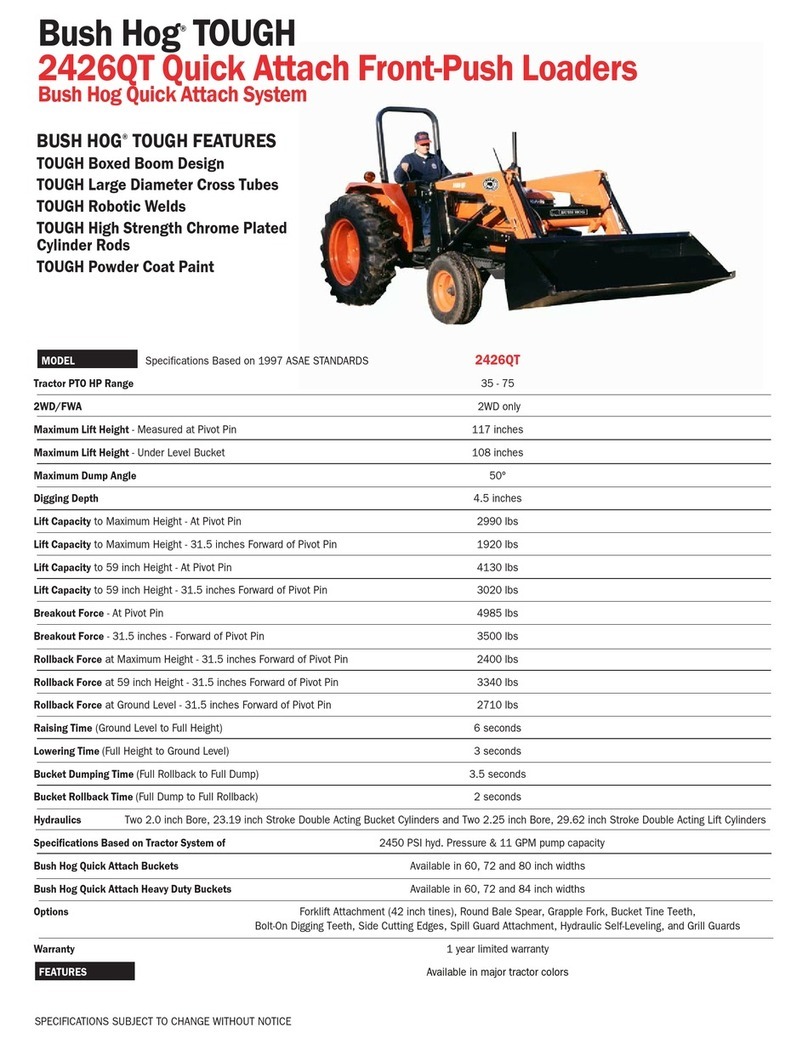

8. SPECIFICATIONS.................................. 41

8.1. Weight of materials................................................... 42