4

4. Installation instruction

To avoid personal injury or death:

APark the machine on a firm and level ground

and set the parking brake.

ALower the bucket to the ground.

ASet all controls in their neutral positions.

ARelease all residual pressure of the hydraulic

system.

AStop the engine. Remove the key from the

ignition.

AThe engine, hydraulic components and

coolants can be hot. Wait until all the

components are cooled down sufficiently to

avoid burns.

AClean the work area and the machine.

ADisconnect the battery negative cable.

AHang a "DO NOT OPERATE" tag on the

operator station.

APut on working clothes and personal protective

equipment.

ARead all instructions and safety instructions in

this bulletin and safety labels on your machine.

AFollow the local safety regulations and/or laws

in your country.

AIf you are working with other people, make sure

that your signals and communications are fully

understandable for additional safety.

ADo not contact fuel tubes to sharp edges, high

temperature parts, and rotating parts.

ADo not stretch fuel tubes excessively.

ADo not clamp fuel tubes with electrical wiring.

ADo not flatten fuel tubes by the clamps.

ATake care not to leak fuel when disconnecting fuel

tubes.

A) Preparation

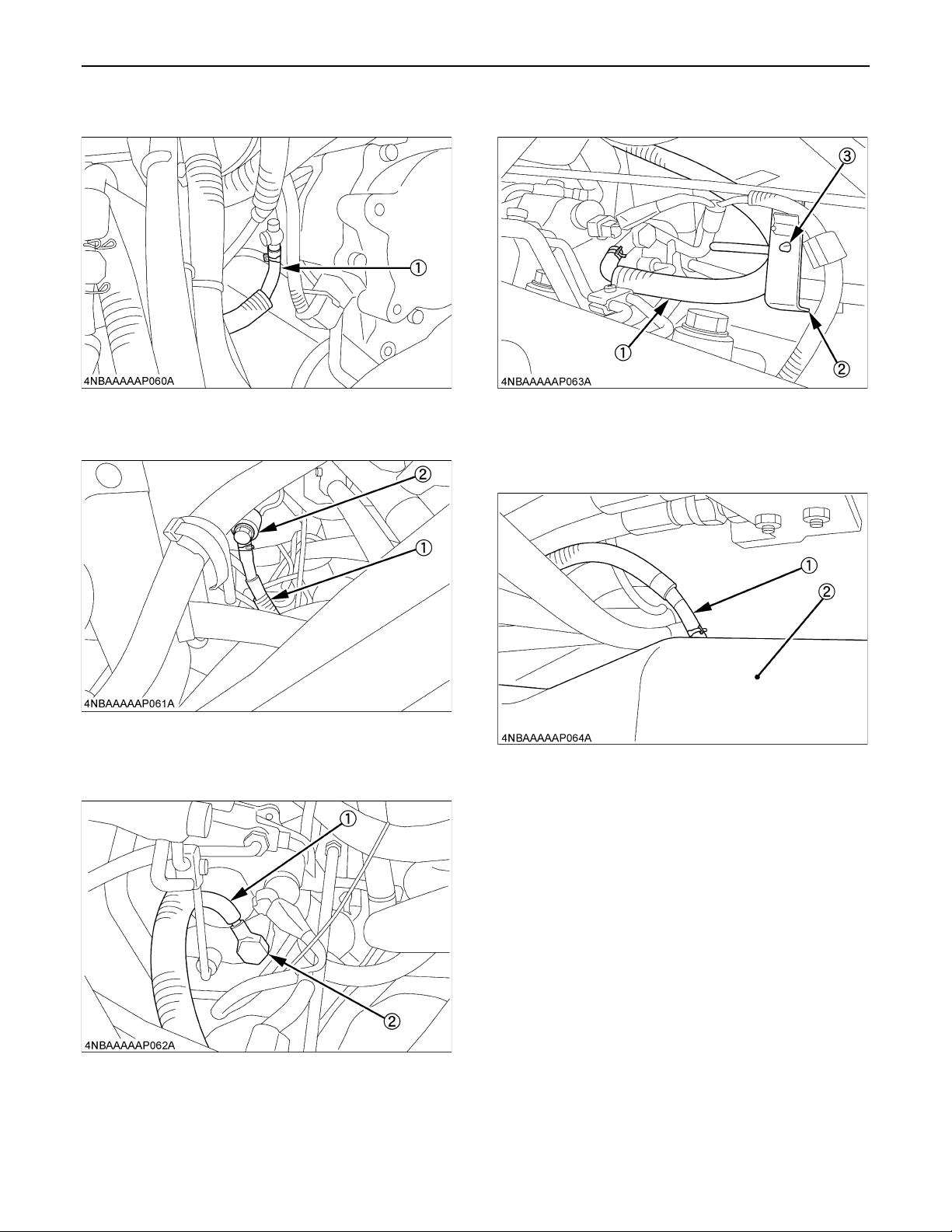

After the following steps 1 to 5, install the necessary parts

according to the installation manual B), C) and D). If

necessary for the details, see the WSM.

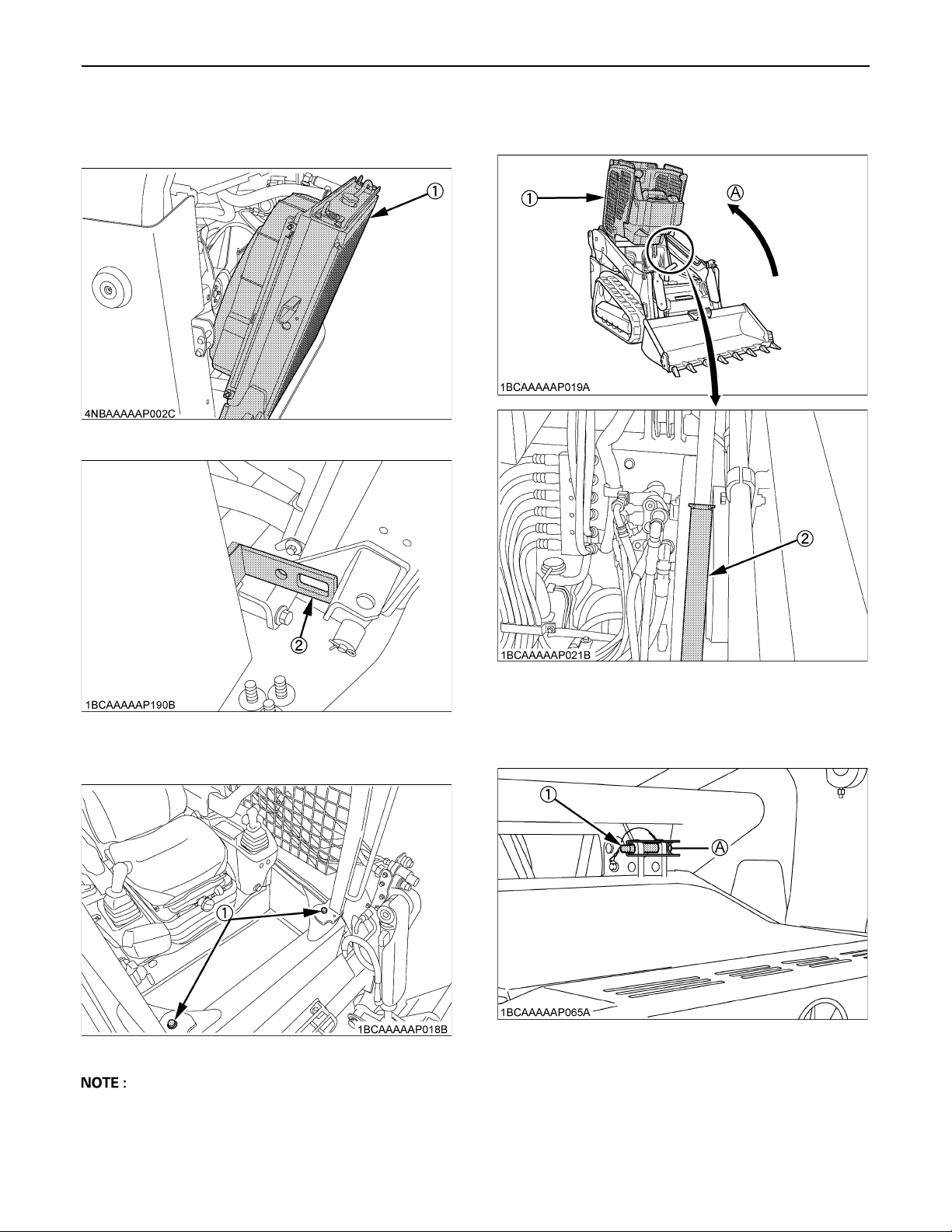

1. Open the rear and upper bonnet (1) (3).

AInsert the pin (2) into the locked position (A) to fix the

rear bonnet.

(1) Bonnet (Rear)

(2) Pin (A) Locked position

(3) Bonnet (Upper)