2

TABLE of CONTENTS

A Description............................................................................................................. 3

B Summary of use .................................................................................................... 4

C Detailed description of the system...................................................................... 6

C 1 Electric power supply................................................................................... 6

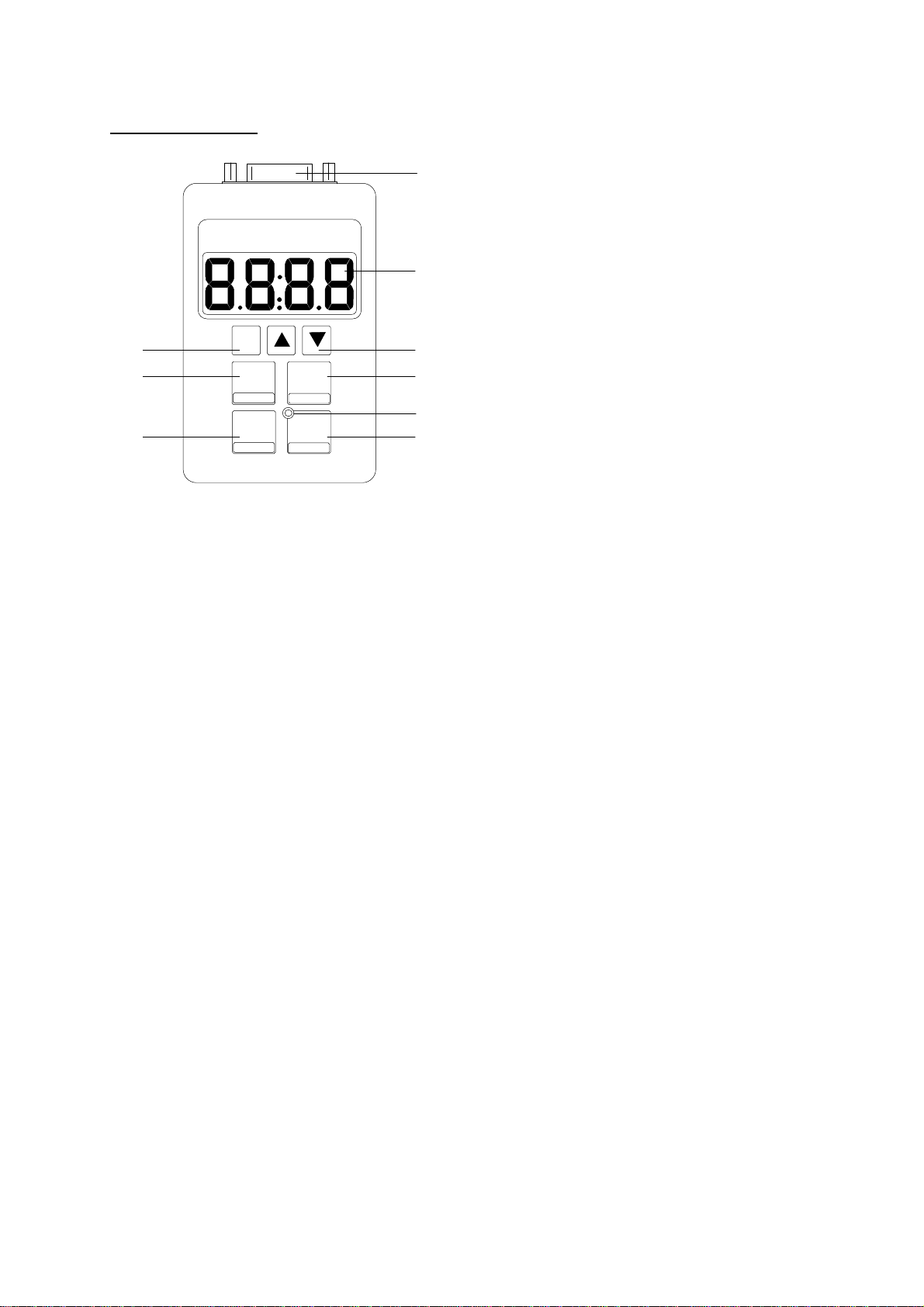

C 2 Design.......................................................................................................... 6

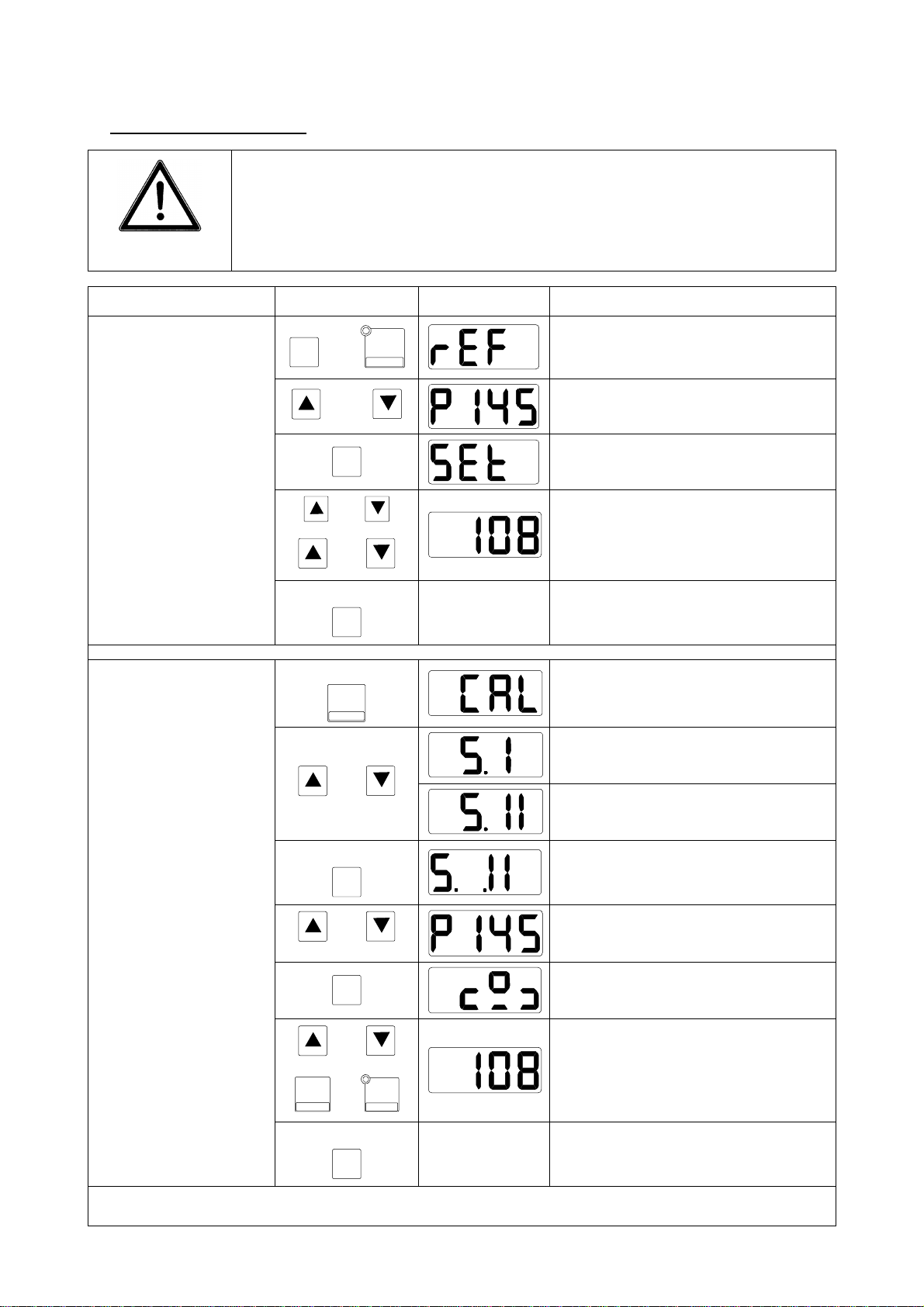

D Work and display settings ................................................................................... 8

D 1 Setting the point of reference ...................................................................... 8

D 2 Opening calibration (flow control)................................................................. 9

D 2.1 Setting the seed type........................................................................ 9

D 2.2 Setting the opening......................................................................... 10

D 2.3 Flow control ................................................................................... 10

D 3 Programming the nominal application rate (100% )................................... 11

D 4 Adjustment to the nominal application rate (100%).................................... 12

D 5 Setting the application rate adjustment level.............................................. 12

D 6 Application rate adjustment in %................................................................ 12

D 7 Setting the null flow rate ............................................................................ 13

E Connection to a « Master » terminal (GPS mode)

E 1 Description................................................................................................. 14

E 2 Work and display settings.......................................................................... 15

F System adjustment and calibration .................................................................. 16

F 1 Adjusting the opening pulses...................................................................... 16

F 2 Adjustment of the opening limit points........................................................ 17

F 3 Screen test................................................................................................. 18

F 4 Rotation sensor test ................................................................................... 18

F 5 Motor and sensor pulse test....................................................................... 18

F 6 Setting the maximum amperage................................................................. 19

F 7 Setting the maximum functioning time under maximum amperage............ 19

G Trouble shooting guide..................................................................................... 20

H Symbols ............................................................................................................. 21