Toro 9701 User manual

Operator’s Manual

Domestic English (EN)

Form No. 3326-190 Rev. B

ProCore 660 and 880 Aerator

Model No. 09701—200000001 and Up

Model No. 09701TE—200000001 and Up

Model No. 09702—200000001 and Up

Model No. 09702TE—200000001 and Up

2

All Rights Reserved

Printed in the USA

W2004 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Contents

Page

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operating Practices 3. . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 5. . . . . . . . . . . . . . .

Specifications 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications–660 Aerator 7. . . . . . . . . .

General Specifications–880 Aerator 7. . . . . . . . . .

Performance Specifications 8. . . . . . . . . . . . . . . . .

Setup 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts Chart 9. . . . . . . . . . . . . . . . . . . . . . . . .

Tractor Requirements 9. . . . . . . . . . . . . . . . . . . . . .

Ballast Requirements 9. . . . . . . . . . . . . . . . . . . . . .

Connect Lower Link Arms 9. . . . . . . . . . . . . . . . .

Connect Upper Link 10. . . . . . . . . . . . . . . . . . . . . . .

Install Side Guards 10. . . . . . . . . . . . . . . . . . . . . . . .

Adjust PTO Shaft Length 10. . . . . . . . . . . . . . . . . . .

Connect PTO Shaft 11. . . . . . . . . . . . . . . . . . . . . . .

Mount Castor/Safety Stand 12. . . . . . . . . . . . . . . . .

Adjusting Sway Links 12. . . . . . . . . . . . . . . . . . . . .

Level Aerator Side–to–side 13. . . . . . . . . . . . . . . . .

Adjust 3-Point Lift Stop 13. . . . . . . . . . . . . . . . . . . .

Install Tines/Tine Heads 13. . . . . . . . . . . . . . . . . . .

Mount Turf Guards 14. . . . . . . . . . . . . . . . . . . . . . .

Adjust Roller Scraper 14. . . . . . . . . . . . . . . . . . . . . .

Adjust Turf Guards 15. . . . . . . . . . . . . . . . . . . . . . .

Removing Aerator from Tractor 15. . . . . . . . . . . . .

Accessory Chart 16. . . . . . . . . . . . . . . . . . . . . . . . . .

Accessory Chart 17. . . . . . . . . . . . . . . . . . . . . . . . . .

Controls 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Depth Adjustment Handles 18. . . . . . . . . . . . . . . . .

Depth Guides 18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjust Tine Depth 19. . . . . . . . . . . . . . . . . . . . . . . .

Depth Chart Guide 21. . . . . . . . . . . . . . . . . . . . . . . .

Tractor Controls 21. . . . . . . . . . . . . . . . . . . . . . . . . .

Principles of Operation 21. . . . . . . . . . . . . . . . . . . .

Training Period 22. . . . . . . . . . . . . . . . . . . . . . . . . .

Before Aerating 22. . . . . . . . . . . . . . . . . . . . . . . . . .

Aerating Procedures 22. . . . . . . . . . . . . . . . . . . . . . .

Transport Operation 22. . . . . . . . . . . . . . . . . . . . . . .

Inspection and Cleanup after Use 23. . . . . . . . . . . .

Operating Tips 23. . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Core Windrower 23. . . . . . . . . . . . . . . . . .

Optional Contour Following Kit 23. . . . . . . . . . . . .

Maintenance 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

Torque Taper Lock Assembly 25. . . . . . . . . . . . . . .

Torque Jackshaft Set Screws 25. . . . . . . . . . . . . . . .

Adjusting Belt Tension 25. . . . . . . . . . . . . . . . . . . .

Replacing Belts 26. . . . . . . . . . . . . . . . . . . . . . . . . .

Storage 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Toro General Commercial Products Warranty 28. .

Introduction

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

serial numbers of your product ready. Figure 1 illustrates

the location of the model and serial numbers on the

product.

1

Figure 1

1. Location of the model and serial numbers

Write the product model and serial numbers in the space

below:

Model No.

Serial No.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard.

However, regardless of the hazard, be extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

3

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

Caution signals a hazard that may cause minor or

moderate injury if you do not follow the recommended

precautions.

This manual uses two other words to highlight

information. Important calls attention to special

mechanical information and Note: emphasizes general

information worthy of special attention.

Safety

Improper use or maintenance by the operator or owner

can result in injury. To reduce the potential for injury,

comply with these safety instructions and always pay

attention to the safety alert symbol, which means

CAUTION, WARNING, or DANGER—“personal

safety instruction.” Failure to comply with the

instruction may result in personal injury or death.

Safe Operating Practices

Before Operating

•Owners of this Aerator must give operators and

employees full operation and safety instructions before

allowing them to operate this machine and at least

annually thereafter. An operator who has not read and

fully understood all operating and safety instructions is

not qualified to operate this machine. Become

familiar with all controls and know how to stop

quickly.

•Do not allow children to operate the machine. Do not

allow adults to operate the machine without proper

instruction.

•Remove all debris or other objects that might interfere

with operation. Keep all bystanders away from the

work area.

•Locate and mark all under ground obstructions such as

irrigation components, electrical or telephone lines.

•Make sure tractor is in neutral and hand brake applied

before starting. Refer to Tractor Operator’s Manual for

safe starting procedures.

•To maintain full steering control, add front end

weights to tractor. Refer to Tractor Operator’s Manual

for weight requirements.

•Keep all shields and safety devices in place. If a

shield, safety device or decal is damaged, repair or

replace it before operation is commenced. Also tighten

any loose nuts, bolts and screws to ensure machine is

in safe operating condition.

•Do not operate machine while wearing sandals, tennis

shoes, sneakers or shorts. Also, do not wear loose

fitting clothing which could get caught in moving

parts. Always wear long pants and substantial shoes.

Wearing safety glasses, safety shoes, ear protection

and a helmet is advisable and may be required by

some local ordinances and insurance regulations.

While Operating

•Keep all bystanders and pets away from the work

area.

•Using the machine demands attention, and to prevent

loss of control:

– Use only in daylight or when there is good

artificial light.

– Watch for holes or other hidden hazards.

– Do not transport machine close to a sand trap,

ditch, creek or other hazard.

– Reduce speed on side hills and before making

sharp turns to prevent tipping or loss of control.

– Look behind the aerator before backing up.

•If the tines strike a solid object or the machine vibrates

abnormally, shut the engine off. Remove key from

ignition switch. Check aerator and traction unit for

damage. Repair any damage before restarting the

engine and operating the tines. Be sure tines are in

good condition and all bolts are tight.

•Before leaving machine unattended, disengage power

to aerator, lower aerator and set parking brake. Stop

engine.

•Never dismount while tractor is in motion. Never get

on or off tractor while engine is running and PTO drive

shaft is engaged. Never step over PTO shaft to reach

other side of aerator – walk around the machine.

•Park aerator on a hard, level surface, install rear

support/safety stand and chock roller before

disconnecting from tractor.

•If it is necessary to probe below the soil surface, use a

non conductive material to prevent electrical shock in

case electrical wires are present.

Transporting

•Be sure you are in compliance with all regulations

regarding transporting equipment on the public roads

and highways.

•Ensure that all reflectors and lights required are in

place and are clean and visible by overtaking and

oncoming traffic.

•Never allow anyone to ride on the machine during

transport.

4

•Reduce speed on rough roads and surfaces.

•Independent brakes should always be locked together

when on the road.

PTO Shaft

•For all PTO shaft steel parts (tubes, bearings, joints

etc). disassembly or repairs, it is highly advisable to

contact your local Toro distributor. Removal of

components for repairs and re–assembly may damage

some parts if not carried out correctly using special

tools available in a dealer’s workshop.

•The PTO shaft should not be used without the guards

supplied, with partial protection, with damaged guard

or without the special anti–rotation chains correctly

hooked, so as to permit the maximum angle of the

PTO shaft without breaking the chains.

Storage Safety

•Store the aerator on a firm level surface.

•Store aerator away from areas of human activity.

•Do not allow children to play on or around the stored

machine.

•Make sure the aerator is sitting, or blocked up firm and

solid and will not sink into soft ground causing it to

tip.

•Ensure that the rear stand pin is secured in place.

•Block the aerator to prevent it from rolling or tipping.

Maintenance

•Before making adjustments or performing maintenance

on the aerator, switch off the engine, stop the PTO and

apply the hand brake before dismounting from the

tractor. Be sure the aerator is on the ground or lowered

onto the rear castor/safety stand.

•Support the machine with the rear castor/safety stand

when working beneath it. Never rely on the tractor’s

hydraulics to support the machine.

•Place all controls in neutral, stop the engine, apply

hand brake and wait for all moving parts to stop before

servicing maintaining, adjusting or unblocking the

aerator.

•Be sure machine is in safe operating condition by

keeping nuts, bolts and screws tight. Check the tine

mounting bolts and nuts frequently to be sure they are

tightened to specification.

•Do not check or adjust belt tension when the tractor

engine is running.

•Be sure all guards are replaced and the hood is secured

shut after maintaining or adjusting the machine.

•Perform only those maintenance instructions described

in this manual. If major repairs are ever needed or

assistance is desired, contact an Authorized Toro

Distributor. To ensure optimum performance and

safety, always purchase genuine Toro replacement

parts and accessories to keep the Toro all Toro. Never

use “will-fit” replacement parts and accessories made

by other manufacturers. Look for the Toro logo to

ensure genuineness. Using unapproved replacement

parts and accessories could void the warranty of The

Toro Company.

5

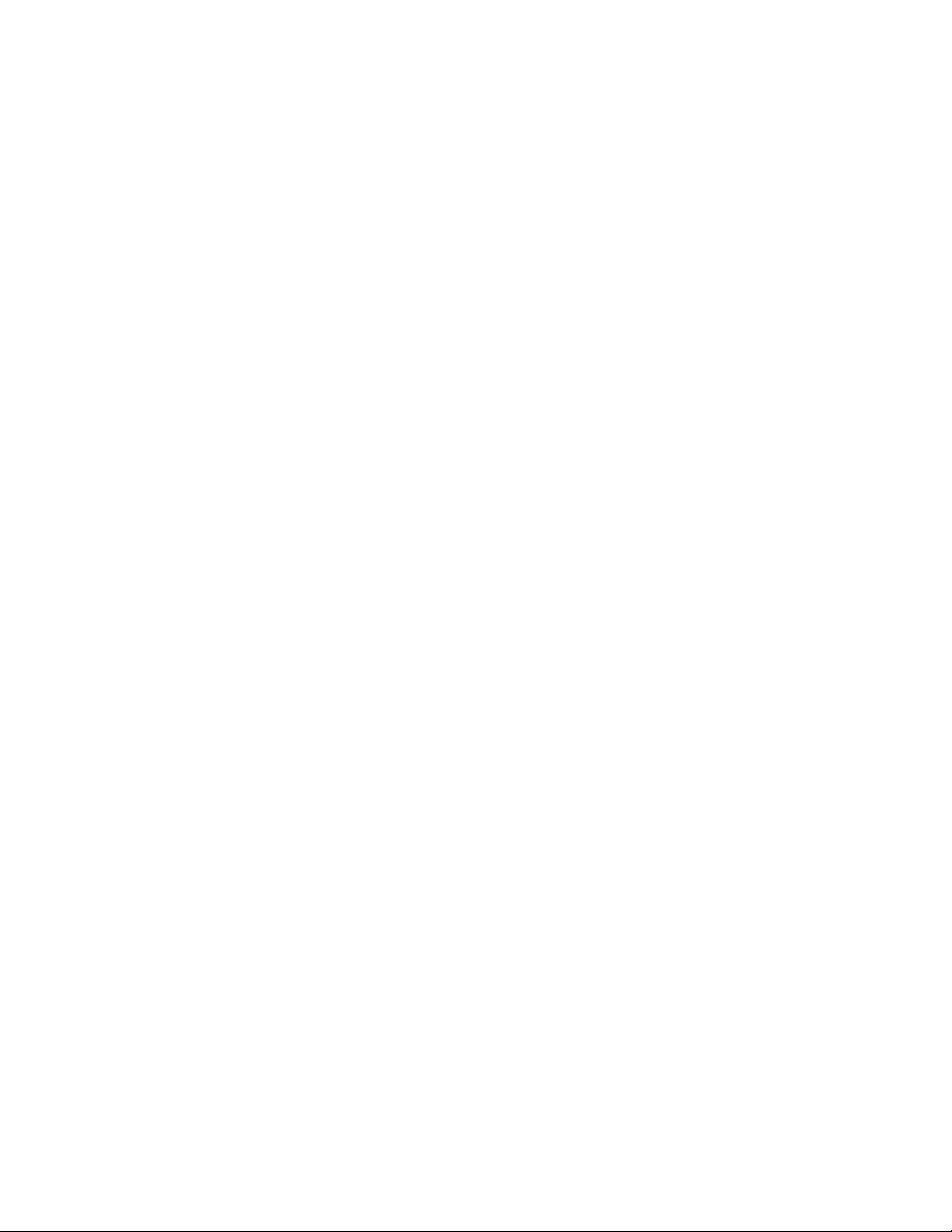

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any

area of potential danger. Replace any decal that is damaged or lost.

93-9879

1. Stored energy hazard—read the Operator’s Manual.

100-3613

1. Full body entanglement hazard—stay away from moving parts

100-3614

1. Crushing hazard of hand and body—use the rear safety stand.

100-5443

1. PTO speed.

100-3611

1. Warning, read the Operator’s Manual—torque lug nuts to 37

ft-lbs (50 N⋅m) at intervals of 10 and 50 hours.

100-5442

1. Depth gauge.

6

100-3612

1. Entanglement hazard—stay away from moving parts

100-3615

1. Warning, read the Operator’s Manual

2. Remove the ignition key and read the instructions before

servicing or performing maintenance.

3. Entanglement hazard—stay away from moving parts.

4. Crushing hazard of hand and body—lower machine to the

ground.

5. Crushing hazard of hand and foot—keep bystanders a safe

distance from the machine.

6. Falling hazard—do not carry passengers.

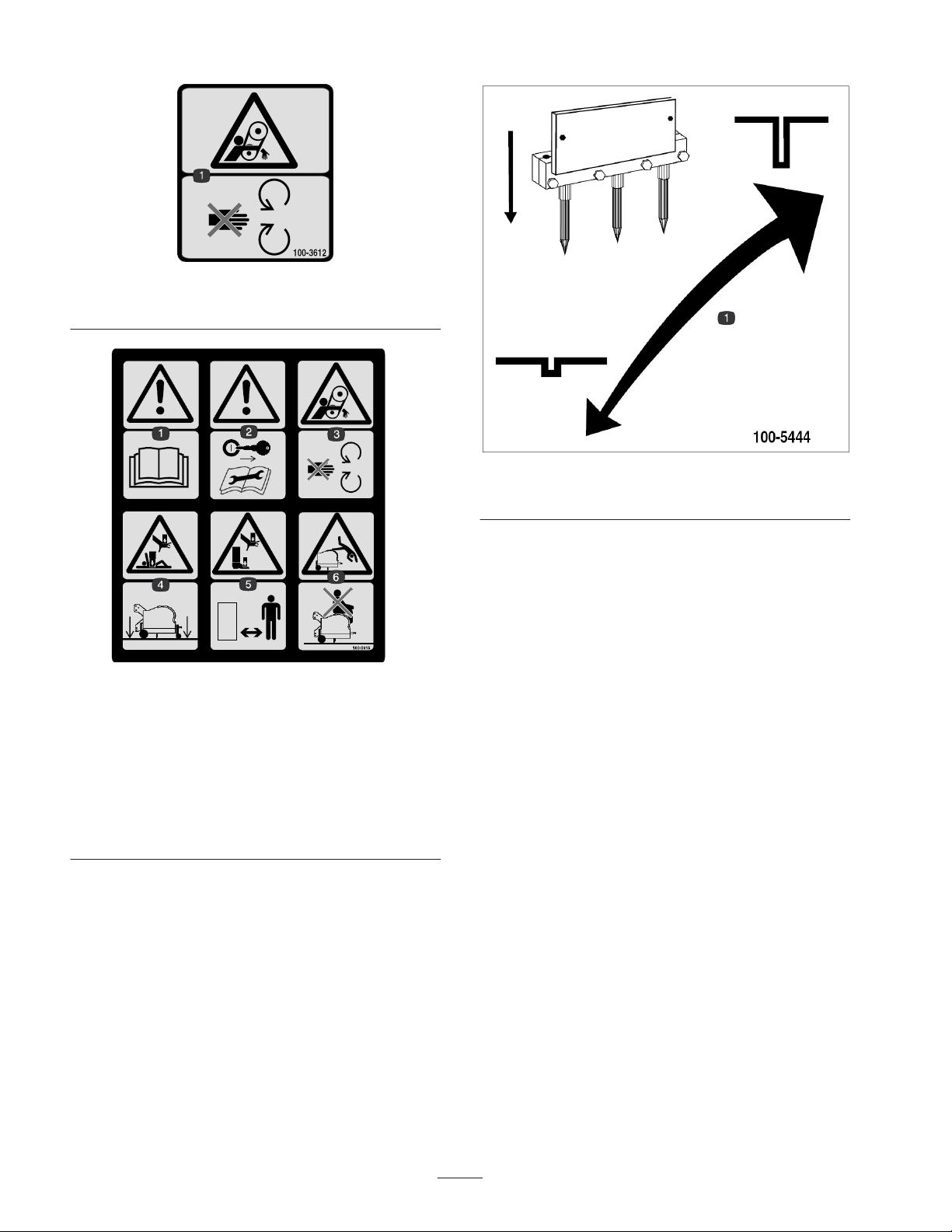

100-5444

1. Raise or lower to adjust depth height

7

Specifications

General Specifications–660 Aerator

Working Width 60” (1.5 m)

Overall Width 72” (1.83 m)

Overall Length 33” (.84 m)

Overall Height 34” (.86 m)

Number of Tine Heads 6

Roller Diameter 6” (152 mm)

Weight 1,220 lbs. (554 Kg)

PTO Speed 540 rpm

Power Requirement 24 hp (17.5 Kw)

Hitch Category Category one, three point linkage

Min./Max. Depth 0” – 4” (0–105 mm)

Drive Belt Section 5VX (3) / Tine Pair

General Specifications–880 Aerator

Working Width 80” (2m)

Overall Width 92” (1.83 m)

Overall Length 33” (.84 m)

Overall Height 34” (.86 m)

Number of Tine Heads 8

Roller Diameter 6” (152 mm)

Weight 1,570 lbs. (640 Kg)

PTO Speed 540 rpm

Power Requirement 32 hp (23 Kw)

Hitch Category Category one, three point linkage

Min./Max. Depth 0” – 4.2” (0–105 mm)

Drive Belt Section 5VX (3) / Tine Pair

8

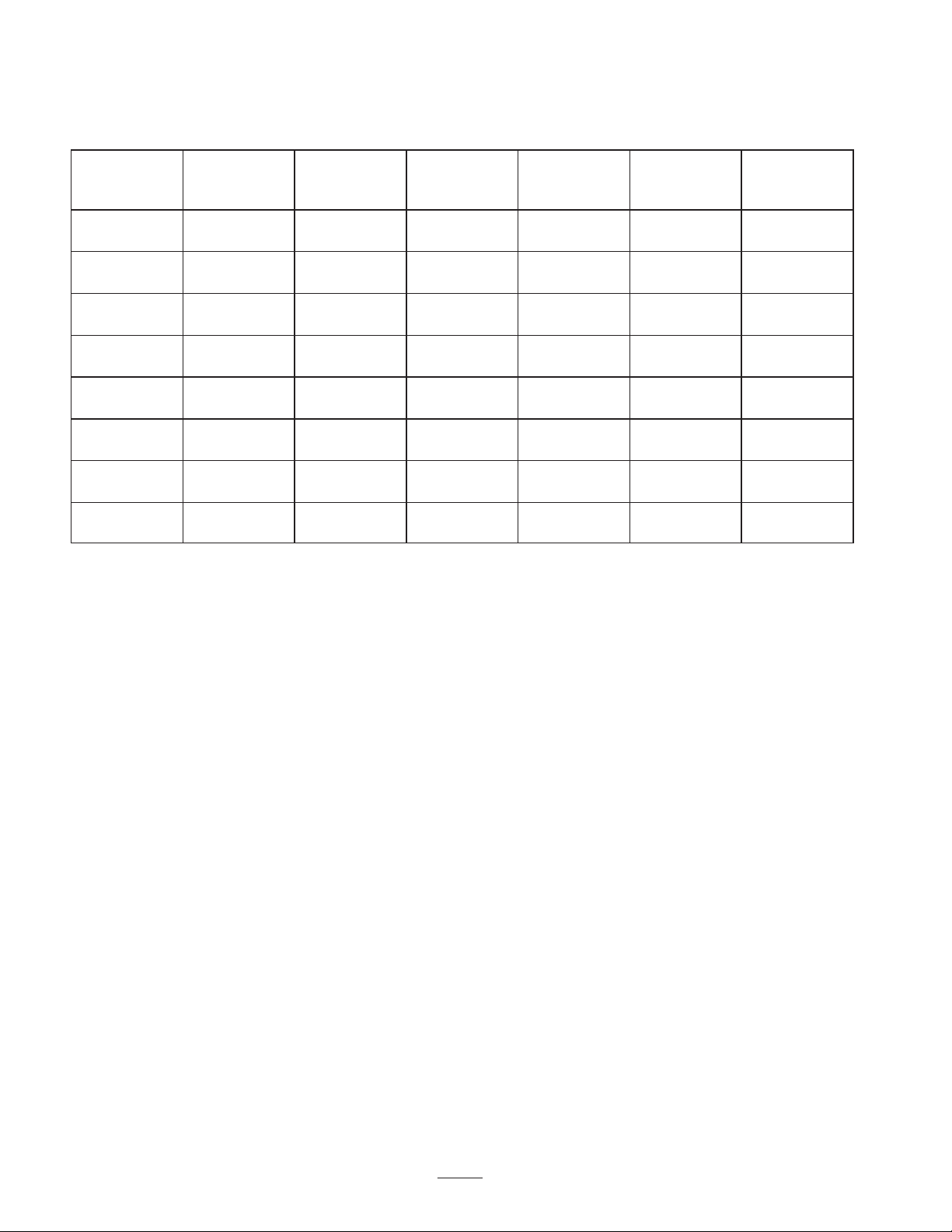

Performance Specifications

mph

(km/hr)

Forward

Hole

Spacings

Lateral Hole

Spacing

Mini Tine

Lateral Hole

Spacing

4 Tine Head

Lateral Hole

Spacing

3 Tine Head

Sq. ft. / Hr.

(Sq. m / Hr.)

660

Sq. ft. / Hr.

(Sq. m / Hr.)

880

0.6 (1) 1” (25 mm) 1.2” (30 mm) 2.4” (62 mm) 3.2” (81 mm) 15,385

(1,403)

20,513

(1,871)

0.8 (1.3) 1.5” (38 mm) 1.2” (30 mm) 2.4” (62 mm) 3.2” (81 mm) 23,008

(1,877)

30,677

(2,503)

1.1 (1.7) 2” (51 mm) 1.2” (30 mm) 2.4” (62 mm) 3.2” (81 mm) 30,769

(2,858)

41,025

(3,811)

1.4 (2.3) 2.5” (64 mm) 1.2” (30 mm) 2.4” (62 mm) 3.2” (81 mm) 38,531

(3,579)

51,375

(4,772)

1.7 (2.7) 3” (76 mm) 1.2” (30 mm) 2.4” (62 mm) 3.2” (81 mm) 46,015

(4,274)

61,353

(5,699)

2.0 (3.2) 3.5” (89 mm) 1.2” (30 mm) 2.4” (62 mm) 3.2” (81 mm) 53,777

(4,995)

71,703

(6,660)

2.2 (3.5) 4” (102 mm) 1.2” (30 mm) 2.4” (62 mm) 3.2” (81 mm) 61,261

(5,690)

81,681

(7,587)

2.5 (4) 4.5” (114 mm) 1.2” (30 mm) 2.4” (62 mm) 3.2” (81 mm) 69,300

(6,437)

92,400

(8,583)

Note: Performance specifications shown are maximum values obtained at rated (540 rpm) PTO speed. Changing engine /

PTO rpm in any particular gear (or fixed hydrostatic pedal position) will not change forward hole spacings, although mph

and productivity specifications will be proportionately changed.

9

Setup

Note: Determine the left and right sides of the machine from the normal operating position.

Loose Parts Chart

Note: Use this chart as a checklist to ensure all parts necessary for assembly have been shipped. If any of these parts are

missing, total setup cannot be completed.

Description Qty. Use

PTO drive shaft 1Transfers power from tractor to aerator

Rear castor/safety shield 1Support aerator for maintenance/storage

Side guards 2Keeps hands and feet away from tines

Keys 2 For hood latch on TE models

Operator’s Manual 2Read before operating machine

Parts Catalog 1Service part identification

Tractor Requirements

•24 horsepower—660

•32 horsepower—880

•Correct tire pressure

•Category one 3 point hitch, rated to lift at least a

1400 lb. (637 Kg) implement–660

•Category one 3 point hitch, rated to lift at least a

1700 lb. (771 Kg) implement–880

•540 rpm tractor PTO

•Adequate front-end weight (ballast)

Ballast Requirements

To help prevent bodily injury and provide added

stability, make sure front of the tractor is

equipped with proper ballast. Refer to tractor

operator’s manual for ballast requirements.

Caution

•Refer to Tractor Operator’s Manual for ballast

requirements.

Connect Lower Link Arms

1. Aerator must be positioned on a flat, level surface for

installation.

2. Back tractor squarely up to aerator until lower link

arms are aligned with hitch pins.

3. Make sure PTO is disengaged.

4. Engage parking brake, STOP engine and remove key

from ignition. Wait for engine and all moving parts to

STOP before leaving operator’s seat on tractor.

5. Insert right and left lower link arms onto hitch pins

(Fig. 2).

1

2

Figure 2

1. Lower link 2. Lynch pin

6. Secure lower link arms to hitch pins with lynch pins

(Fig. 2).

10

Connect Upper Link

Note: Front of aerator must be vertical or angle forward

slightly while operating for best aeration hole quality

(Fig. 3).This angle will change when depth adjustments

are made. Adjust upper link to control this angle. Refer to

Operation, page 17 for additional information.

90_

0–8_

Operating

Range

Figure 3

1. Connect upper link to lower hole in bracket and secure

with link pin and lynch pin (Fig. 4).

1

2

3

Figure 4

1. Upper link

2. Link pin

3. Lynch pin

2. Rotate adjusting link to tighten the link. Do not

overtighten to raise the back end of the aerator off the

ground.

3. Tighten lock nut to secure upper link into position.

Install Side Guards

1. Remove 4 nuts, lockwashers and washers loosely

secured to each bottom end of aerator frame.

2. Position appropriate side guard (left or right) onto

mounting studs (Fig. 5).

1

Figure 5

1. Side guard (LH)

3. Secure each side guard to mounting studs with washers

and nuts previously removed.

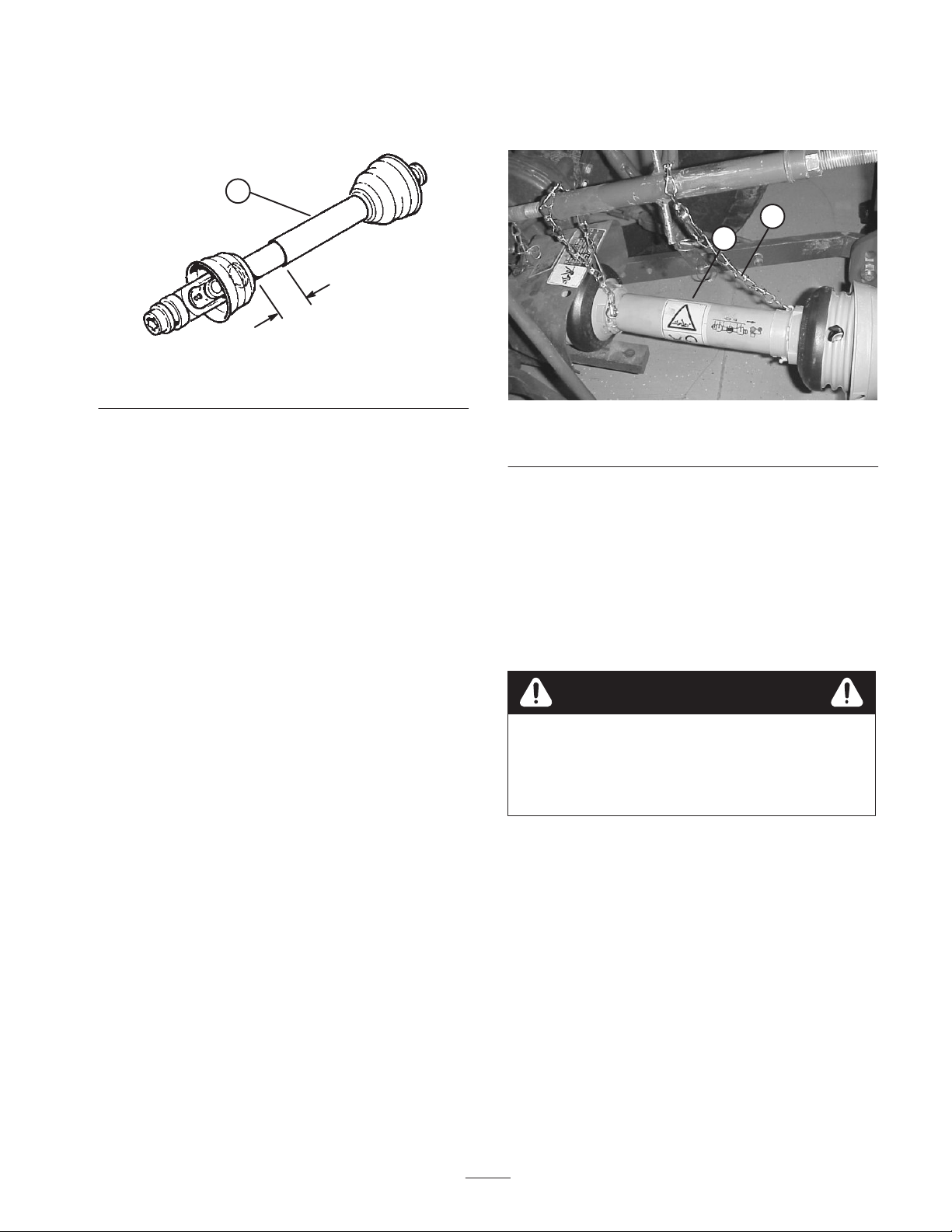

Adjust PTO Shaft Length

Important A long PTO shaft is supplied with machine

to accommodate large variations in the tractor’s PTO and

3 point locations. For most tractors this shaft is too long

and must be cut to correct length or gearbox damage may

result.

1. With the aerator vertical or angled slightly forward,

lower the aerator until the gear box shaft is

approximately the same height as the tractor PTO

shaft. This is the shortest distance between the two

shafts.

2. Measure the distance from the lock groove of the

tractor PTO shaft to the lock groove of the aerator

gearbox PTO shaft. Record this dimension.

3. Fully collapse PTO shaft and measure the distance

between the lock pin collars. Record this dimension.

4. At it’s shortest length, the two halves of the PTO shaft

must have at least 1.5 inches (37 mm) of additional

clearance to collapse (Fig. 6). If the dimension in step

2 is not at least 1.5 inches (37 mm) greater than the

11

dimension in step 3, the PTO shaft is too long, proceed

to step 5. If there is enough clearance to allow PTO

shaft to collapse, proceed to step 10.

1.5”

(37 mm)

1

Figure 6

1. PTO shaft

5. Use the following calculation to establish how much

shorter the shaft must be, when connected, to ensure a

clearance of 1.5 inches (37 mm).

A. Subtract the dimension recorded in step 3 from the

dimension recorded in step 2. Record this

dimension.

B. Subtract the result in step 5A from 1.5” (37mm).

The PTO shaft must be shortened by this amount.

6. Using a hacksaw, cut the yellow guards and the steel

tubes shorter by the calculated length. Cut both halves

of the PTO shaft

7. Deburr ends of steel tubes internally and externally.

8. Remove all debris from tube sections.

9. Grease steel tubes liberally.

10. Assemble PTO shaft and secure to aerator and tractor.

11. Measure the shaft. If not at least 1.5 inches (37 mm),

repeat procedure.

12. Raise aerator to highest position. There must be at

least 3 inches (75 mm) of overlap of the halves. Adjust

3 point lift stop, if necessary. Refer to Adjust 3 Point

Lift Stop, page 11.

Connect PTO Shaft

1. Connect PTO shaft to gearbox input shaft (Fig. 7).

1

2

Figure 7

1. PTO shaft 2. Safety chains

2. Connect PTO shaft to rear tractor PTO shaft.

3. Slide PTO shaft forward as far as it will go.

4. Depress pin to secure PTO shaft in place. Slide PTO

shaft back and forth to make sure it is properly locked.

5. Connect shield safety chains from powershaft sections

to welded clips on link arms or to PTO shields. Make

sure chains remain slack when aerator is raised or

lowered.

To help prevent bodily injury, keep all PTO

shields in place and connect shield chains to link

arms or PTO shields to prevent shields from

rotating during operation.

Caution

12

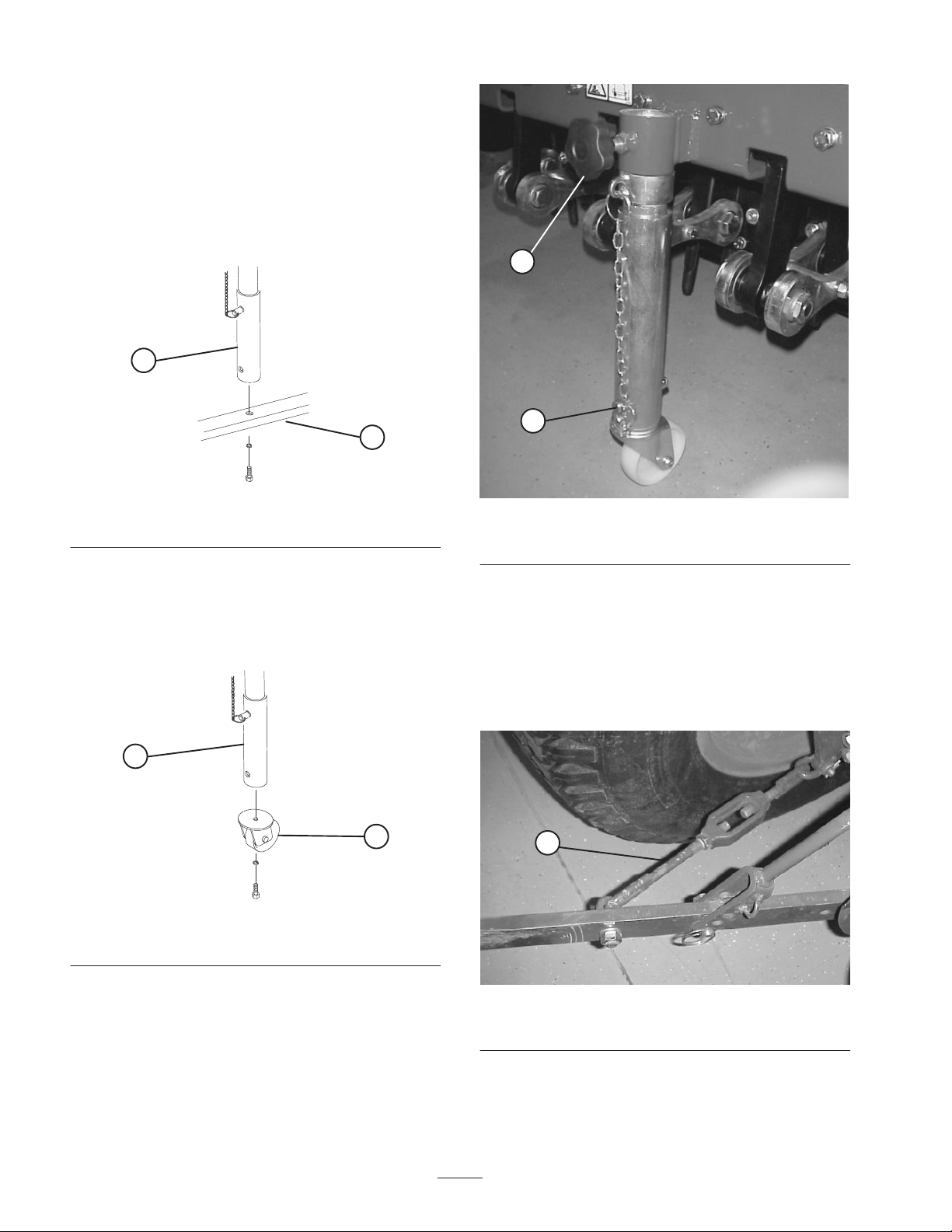

Mount Castor/Safety Stand

Note: Use castor wheel to move aerator around on a hard

surface, as aligning to tractor for installation or for

storage. Level aerator by adjusting roller until the point of

the depth adjustment arrow is just above the side guards.

1. Remove bolt and nut securing rear castor/safety stand

tube to shipping pallet (Fig. 8). Retain bolt and washer

for installation of castor wheel.

1

2

Figure 8

1. Shipping pallet 2. Castor/safety stand

2. Raise aerator off pallet.

3. Remove pallet.

4. Mount castor wheel to rear castor/safety stand tube

with bolt and washer previously removed (Fig. 9).

1

2

Figure 9

1. Castor wheel 2. Castor/safety stand

5. Rear castor/safety stand has two positions:

•Collapsed for aerator storage

•Extended for aerator maintenance

6. Secure castor/safety stand in desired position with pin

(Fig. 10). Tighten castor knob.

1

2

Figure 10

1. Pin 2. Castor knob

7. Slowly lower aerator to the ground.

Adjusting Sway Links

Adjust sway links on lower draft arms of 3-point hitch to

minimize side-to-side sway to a maximum of 1 inch

(25 mm) on each side (Fig. 11).

1

Figure 11

1. Sway link

1. Adjust the lower links inboard until they contact the

aerator mounting plates. This will reduce the stress on

the pins. If the tractor has sway chains instead of sway

13

links, it is recommended that washers be installed

between the lower link arm and lynch pin to reduce the

over hung load on the lift pins.

Note: Refer to tractor operator’s manual for additional

installation and adjustment procedures.

Level Aerator Side–to–side

1. Park tractor and aerator on a level, firm surface. Make

sure both depth gauges are set at the same setting.

2. Place level on top of aerator hood to check for level

side-to-side (Fig. 12).

1

Figure 12

1. Level 2.

3. Turn the adjustable link body (if provided) to raise or

lower the link arm until the aerator is leveled

side–to–side.

Note: Refer to tractor operator’s manual for additional

adjustment procedures.

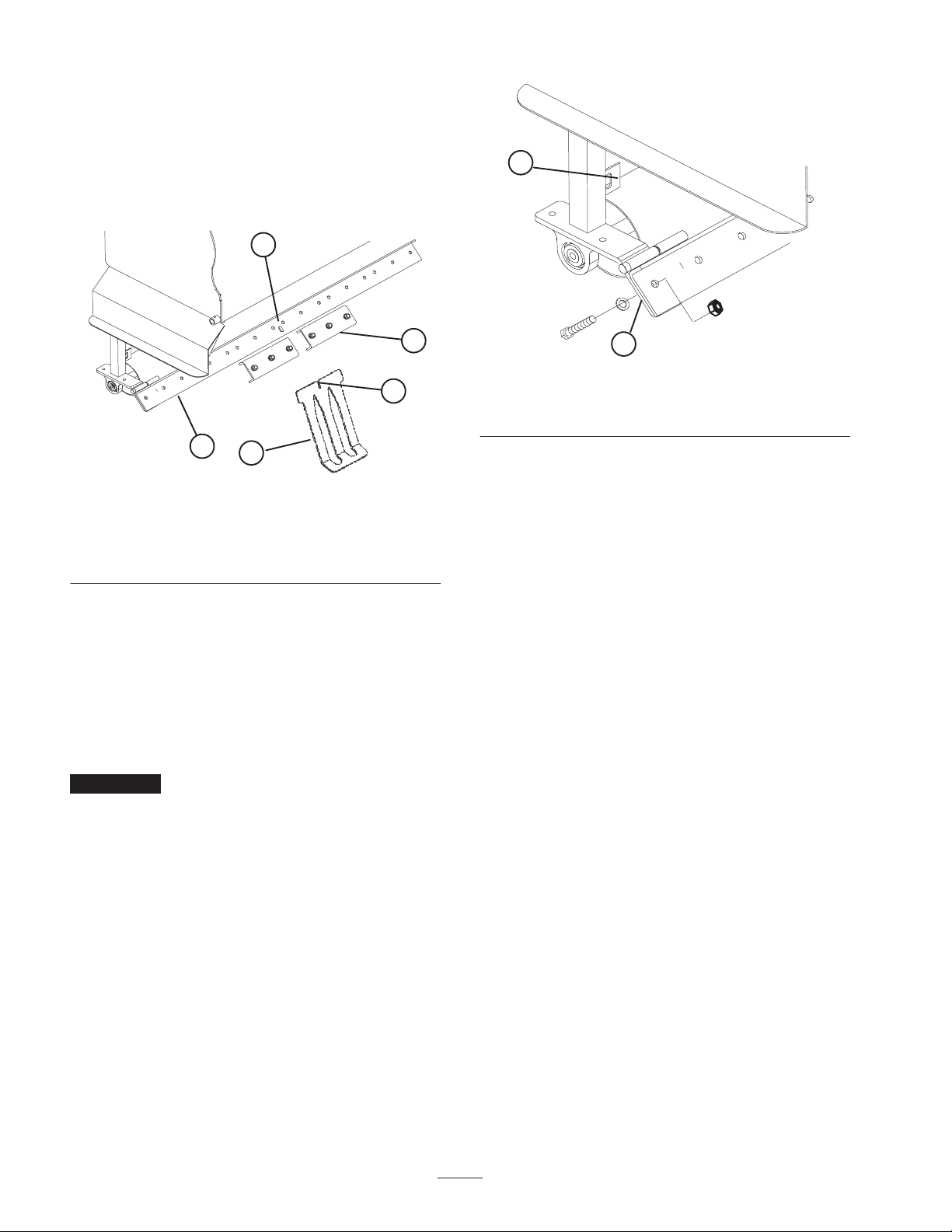

Adjust 3-Point Lift Stop

Adjust and set 3 point lift stop (Fig. 13) to provide

approximately 4” ground clearance, when in the raised

position, to minimize PTO angle when raising aerator. For

transporting or trailer loading/unloading, the full lift range

can be used as long as the PTO tubes do not slide apart.

Operating the PTO in the fully raised position may

damage the PTO or other components.

1

Figure 13

1. 3-Point lift stop

Note: Refer to tractor operator’s manual for adjustment

procedures.

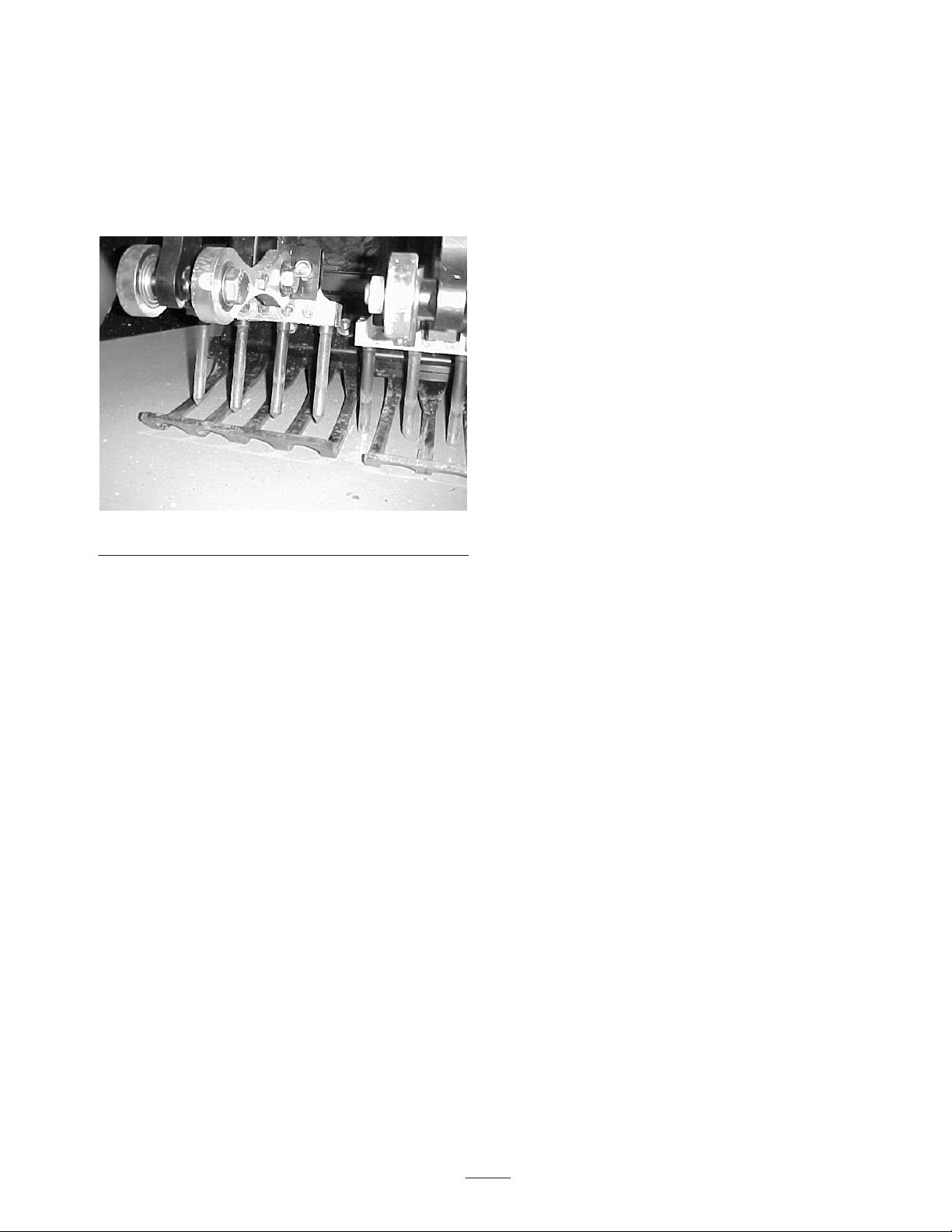

Install Tines/Tine Heads

A wide selection of tines and tine heads are available for

the aerator. Choose the tine type, size and spacings

required for the job. Install the tine head and tines per

Installation Instructions supplied with each tine kit. Refer

to accessory chart on page 13, for required tines.

Important Never operate the aerator without the

tine heads installed. The arms will move excessively

and may damage the aerator frame.

14

Mount Turf Guards

A wide selection of turf guards are available for the

aerator. Choose the required turf guards per accessory

chart on page 13.

1. Loosen nuts securing turf guard clamps to turf finger

tool bar (Fig. 14).

1

2

3

4

5

Figure 14

1. Turf guard

2. Turf finger tool bar

3. Turf guard clamp

4. Notch

5. Locator key

2. Slide appropriate turf guard under center turf guard

clamp while inserting notch onto locator key of turf

finger bracket (Fig. 14). Refer to accessory chart note,

page 13.

3. Tighten nuts securing turf guard and center turf guard

clamp to turf finger bracket.

4. Working outward, mount remaining turf guards to each

side and secure turf guard clamps.

Important From the rear of the machine, check that

the tines line up with the center of the gaps in the turf

guards.

5. To decrease down pressure of turf guards:

A. Remove nuts securing each end of turf finger

bracket to roller legs (Fig. 15).

1

2

Figure 15

1. Spacer location ( 1 each

end)

2. Roller scraper tab

B. Pivot turf finger bracket upward and insert a

washer onto each stud.

C. Pivot turf finger downward onto studs and check

angle.

D. Install nuts to secure assembly.

Note: Aeration depth may need to be reduced to ensure

clearance between the tine heads and the turf guards.

Check clearance before aerating.

Note: To aid in the loading/unloading of the aerator from

a trailer, remove nuts securing each end of turf finger tool

bar to roller legs and pivot turf finger tool bar upward.

Adjust Roller Scraper

Adjust roller scraper so there is approximately a 1/8”

(3mm) gap between scraper and roller.

1. Loosen fasteners securing each end of scraper to roller

scraper tab (Fig. 14).

2. Slide the roller scraper up or down to required position

and tighten fasteners.

15

Adjust Turf Guards

Before starting your new aerator, remove the rear castor

stand and lower the machine on the 3–point linkage until

the depth control roller is resting on the ground. From the

rear of the machine, check that the tines line up exactly

with the center of the gaps in the turf guards. Install the

correct turf guards (Fig. 16), if necessary.

Figure 16

Note: Turf with a good root structure may not require the

turf guards. If this is the case. Do not remove the turf

guard tool bar as this adds support to the roller leg

assembly. Just remove the plastic fingers from the turf

guard bracket.

Removing Aerator from Tractor

1. Stop vehicle on a level surface, not on a slope.

2. Disengage the PTO and engage the parking brake.

3. Stop the engine and remove the key from ignition

switch.

4. Before leaving the operator’s seat on tractor, wait for

engine and all moving parts to stop.

5. Install rear castor/safety stand, collapse it to storage

position and install pin. Tighten knob.

Note: Aerator can be stored on original shipping pallet if

desired. Remove castor wheel.

6. Disconnect safety shield chains from PTO tractor.

Secure end of chain to aerator side of PTO shaft to

prevent PTO shaft from coming apart.

7. Slowly lower aerator until rear castor/safety stand

contacts ground.

8. Lower roller, by adjusting depth control handles, until

roller contacts ground.

9. Loosen locking nut and rotate adjusting link to release

tension between aerator and tractor.

10. Remove lynch pin and top link pin securing center link

to bracket.

11. Push release pin to disconnect powershaft from tractor

PTO shaft.

12. Slide powershaft back and remove from tractor.

13. Remove lynch pins and slide lower link arms off hitch

pins.

16

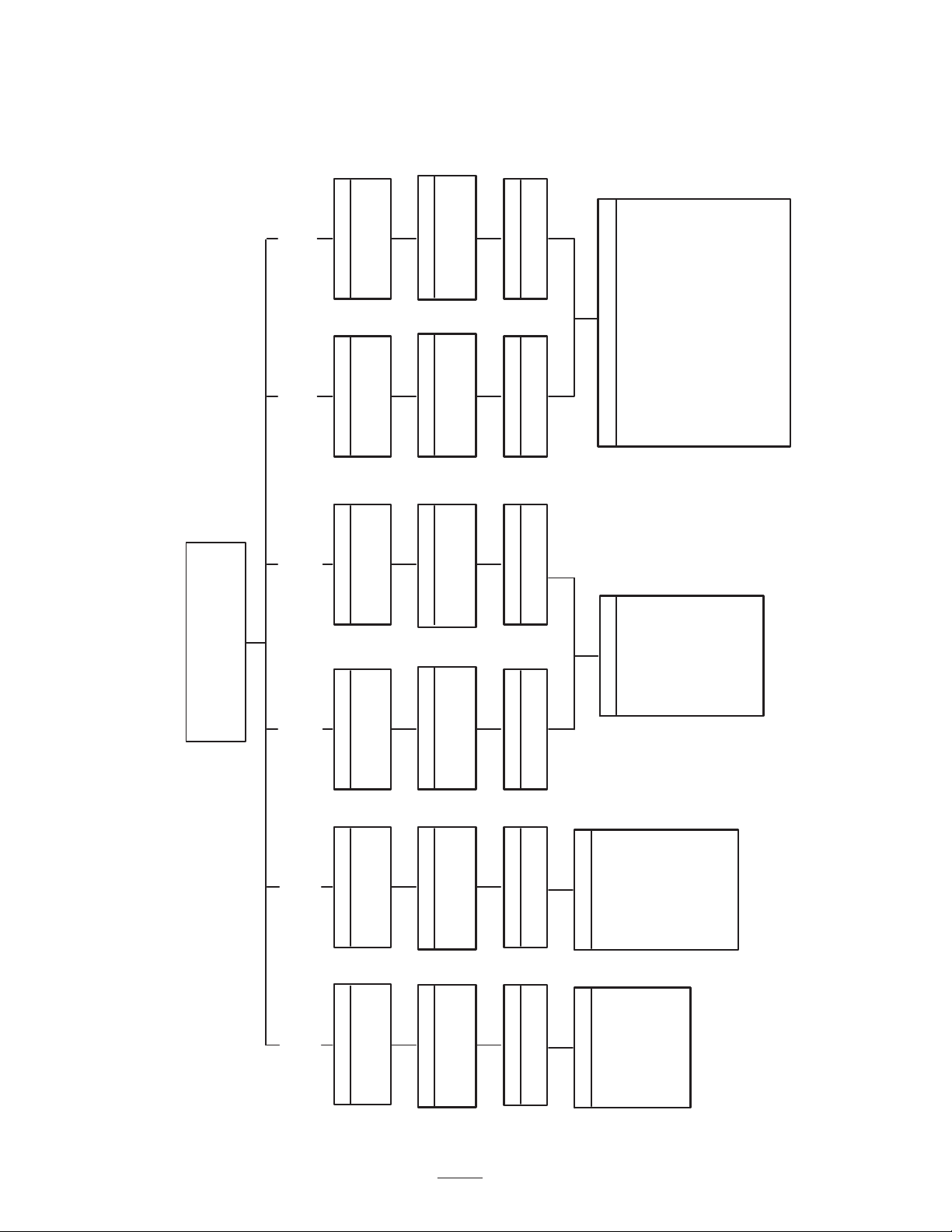

Accessory Chart

.75” (19 mm)

Side Eject

Tine=92-7900

6 Required

Model No. 09720

Heads Required

4 Tine Heavy

Duty Head

(2.4” spacing)

3 Tine Heavy

Duty Head

(3.2” spacing)

8 Mini Tine

Head

(1.2” spacing)

6 Needle Tine

Head

(1.6” spacing)

3 Tine Head

(3.2” spacing)

4 Tine Head

(2.4” spacing)

Heads Required Heads Required Heads Required Heads RequiredHeads Required

6 Required

Model No. 09721

6 Required

Model No. 09733

6 Required

Model No. 09734

6 Required

Model No. 09722

6 Required

Model No. 09723

Turf Guards Required

6 x #100-5418

1 x #100-5419*

Turf Guards Required

1 x #100-5420*

8 x #100-5421

Turf Guards Required

2 x #100-5414

3 x #100-5415*

Turf Guards Required

5 x #100-5416

Turf Guards Required

2 x #100-5414

3 x #100-5415*

Turf Guards Required

5 x #100-5416

Heads RequiredHeads Required

Tines Required

36 Required

Tines Required

48 Required

Tines Required

18 Required

Tines Required

24 Required

Tines Required

18 Required

Tines Required

24 Required

Tine Options

.20” (5 mm)

Needle

Tine=100-3620

.31” (8 mm)

Needle

Tine=100-3621

.37” (9.5 mm)

Mini Solid

Tine=100-3622

.25” (6.5 mm)

Side Eject

Tine=94-3417

Tine Options

.83” (21 mm)

Side Eject

Tine=104-9877

.75” (19 mm)

Hollow

Tine=86-9720

Tine Options

.35” (9 mm) Solid Tine=#100-3626

.39” (10 mm) Solid Tine=#100-3627

.43” (11 mm) Solid Tine=#100-3628

.51” (13 mm) Solid Tine=#100-3629

.63” (16 mm) Solid Tine=#100-3630

.39” (10 mm) Hollow Tine=#100–3633

.51” (13 mm) Hollow Tine=#100-3634

.63” (16 mm) Hollow Tine=#100-3635

.63 (16 mm) HD Side Ejection Hollow

Tine=104-9876

.75” (19 mm) HD Side Ejection Hollow

Tine=#104-9875

Tine Options

.20” (5 mm)

Mini Side Eject

Tine=100-3625

ProCore 600 Aerator

Model Number 09701

Model Number 09701TE

Note: One of these turf guards must be installed in center position.

17

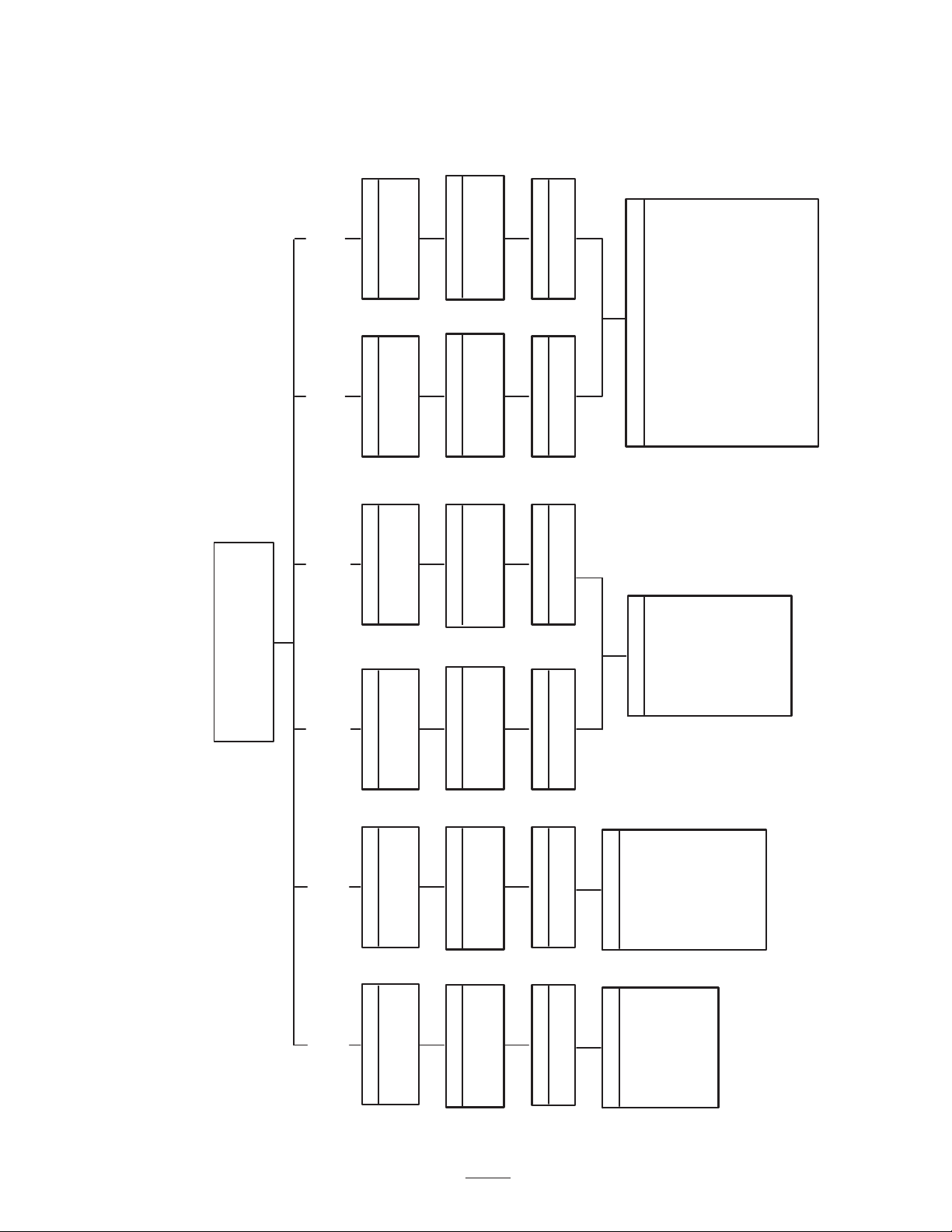

Accessory Chart

.75” (19 mm)

Side Eject

Tine=92-7900

8 Required

Model No. 09720

Heads Required

4 Tine Heavy

Duty Head

(2.4” spacing)

3 Tine Heavy

Duty Head

(3.2” spacing)

8 Mini Tine

Head

(1.2” spacing)

6 Needle Tine

Head

(1.6” spacing)

3 Tine Head

(3.2” spacing)

4 Tine Head

(2.4” spacing)

Heads Required Heads Required Heads Required Heads RequiredHeads Required

8 Required

Model No. 09721

8 Required

Model No. 09733

8 Required

Model No. 09734

8 Required

Model No. 09722

8 Required

Model No. 09723

Turf Guards Required

7 x #100-5419

Turf Guards Required

5 x #100-5420*

4 x #100-5421

Turf Guards Required

5 x #100-5414

Turf Guards Required

1 x #100-5416*

4 x #100-5417

Turf Guards Required

5 x #100-5414

Turf Guards Required

1 x #100-5416*

4 x #100-5417

Heads RequiredHeads Required

Tines Required

48 Required

Tines Required

64 Required

Tines Required

24 Required

Tines Required

32 Required

Tines Required

24 Required

Tines Required

32 Required

Tine Options

.20” (5 mm)

Needle

Tine=100-3620

.31” (8 mm)

Needle

Tine=100-3621

.37” (9.5 mm)

Mini Solid

Tine=100-3622

.25” (6.5 mm)

Side Eject

Tine=94-3417

Tine Options

.83” (21 mm)

Side Eject

Tine=104-9877

.75” (19 mm)

Hollow

Tine=86-9720

Tine Options

.35” (9 mm) Solid Tine=#100-3626

.39” (10 mm) Solid Tine=#100-3627

.43” (11 mm) Solid Tine=#100-3628

.51” (13 mm) Solid Tine=#100-3629

.63” (16 mm) Solid Tine=#100-3630

.39” (10 mm) Hollow Tine=#100–3633

.51” (13 mm) Hollow Tine=#100-3634

.63” (16 mm) Hollow Tine=#100-3635

.63 (16 mm) HD Side Ejection Hollow

Tine=104-9876

.75” (19 mm) HD Side Ejection Hollow

Tine=#104-9875

Tine Options

.20” (5 mm)

Mini Side Eject

Tine=100-3625

ProCore 880 Aerator

Model Number 09702

Model Number 09702TE

Note: One of these turf guards must be installed in center position.

18

Controls

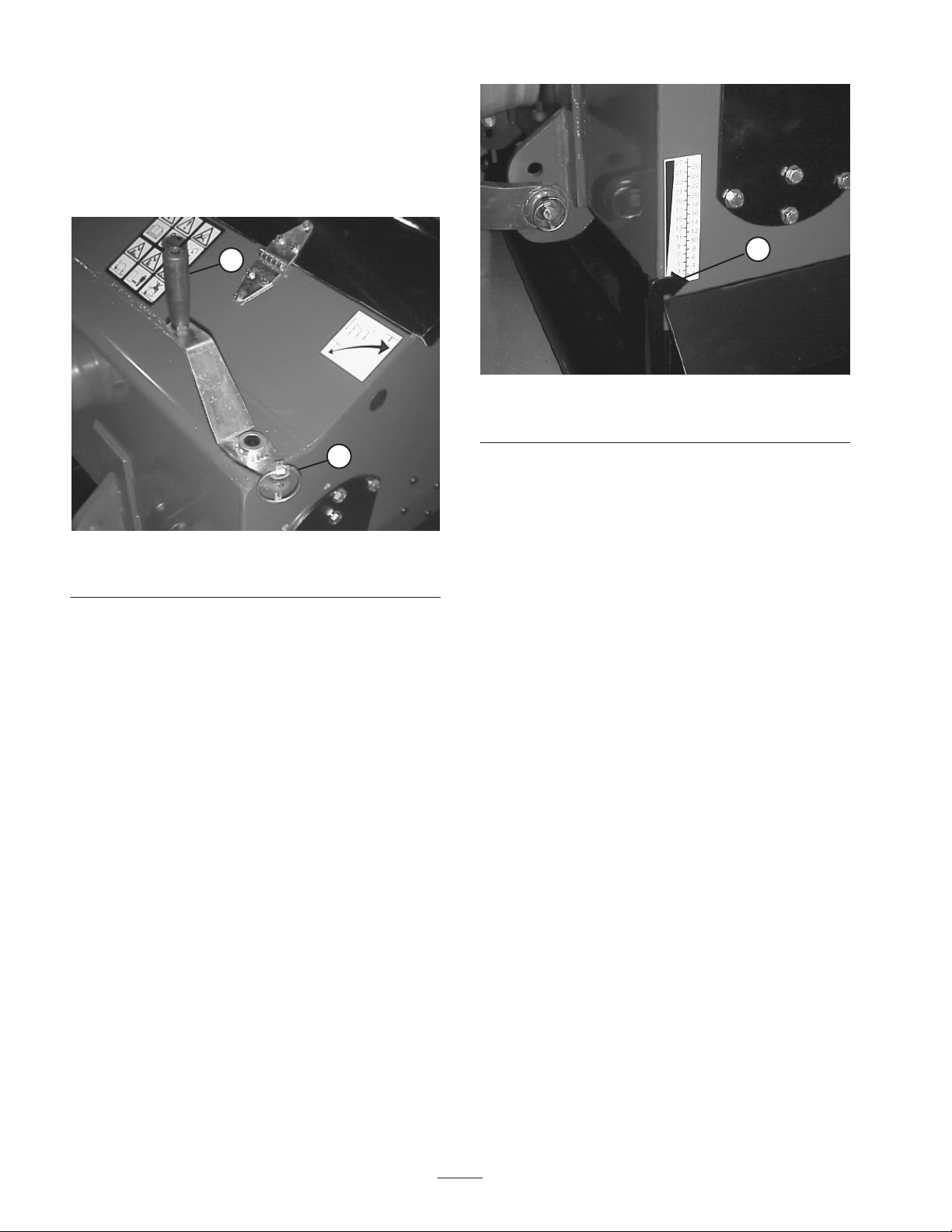

Depth Adjustment Handles

Remove lynch pins, rotate handles to raise or lower tines

to desired depth and replace lynch pins (Fig. 17).

1

2

Figure 17

1. Depth adjustment handle 2. Lynch pin

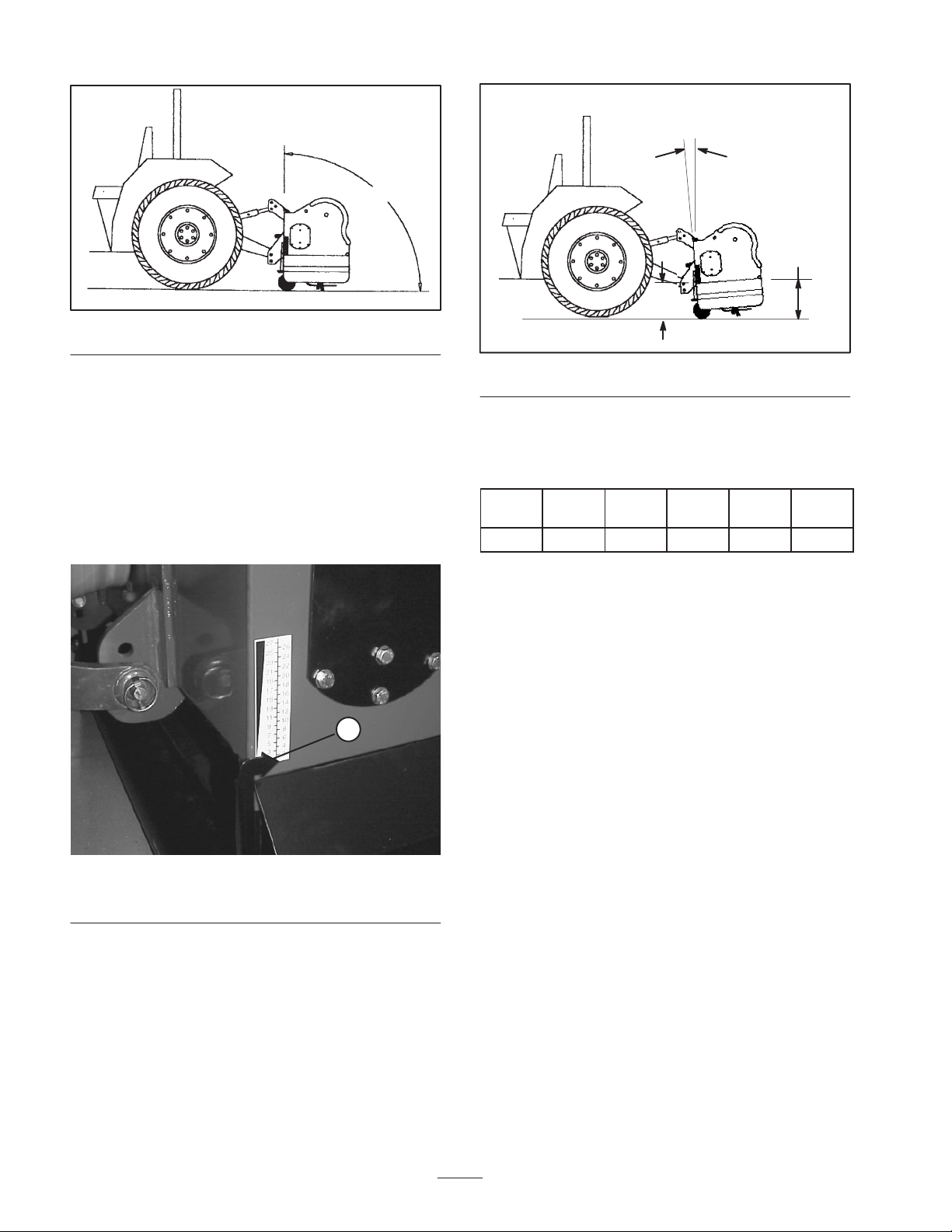

Depth Guides

Depth guides (1 thru 27) are provided to give equal

increments for adjustment. The numbers do not relate to

measurements of depth as this changes with tine type and

amount of tine wear. Adjustment between two numbers

will give approximately .20 inches (5 mm) change in

depth. The higher the number, the deeper the tine

penetration. Always adjust each side to the same number

(Fig. 18).

1

Figure 18

1. Depth guide

19

Operation

Adjust Tine Depth

To adjust the working depth of the tine, proceed as

follows:

1. Remove the lynch pin from each depth adjust handle

(Fig. 19).

1

Figure 19

1. Depth adjustment handle

2. Turn the depth adjuster handles to raise (deeper) or

lower (shallow) the roller.

Note: Make sure that the roller is on the ground once the

depth is chosen.

3. Depth guides (Fig. 20) are provided with numbers 1

through 27. Depth varies with the mounted angle of

aerator, tine type and amount of tine wear. Refer to

Depth Chart on page 16. Adjustment between two

numbers will give approximately 0.20 inches (5 mm)

change in depth. The higher the number, the deeper the

tine penetration. Always adjust each side to the same

number.

1

Figure 20

1. Depth guide

Important If a large change in height is required,

adjust each leg by a small amount to ensure the roller legs

are adjusted as evenly as possible.

Note: Remember when depth changes are made, you will

need to adjust the top link length to give the correct

machine angle. Refer to Connect Upper Link, page 8.

Important Tine depth is affected by the mounted

angle of the aerator as well as the depth setting. If the

aerator is angled rearward, the tine heads may contact the

turf guards and damage may occur. Depths 26 & 27

cannot be used when the aerator is in the vertical position.

See Depth Chart.

4. Install the depth adjust handle lynch pins before

running the machine, even if you are just testing for

correct depth.

Important Tine depth is determined by the tine type,

depth adjustment, amount of tine wear and mounted angle

of the aerator. Refer to Depth Chart on page 18.

Important Maximum depth is achieved when the

aerator is mounted vertically (Fig. 21) and the depth

adjustment set at 25. In this condition, do not operate at

greater depth settings, as there is minimal clearance

between the tine head and the turf guards. Never operate

with the aerator angled rearward or damage to the turf

guards may occur.

20

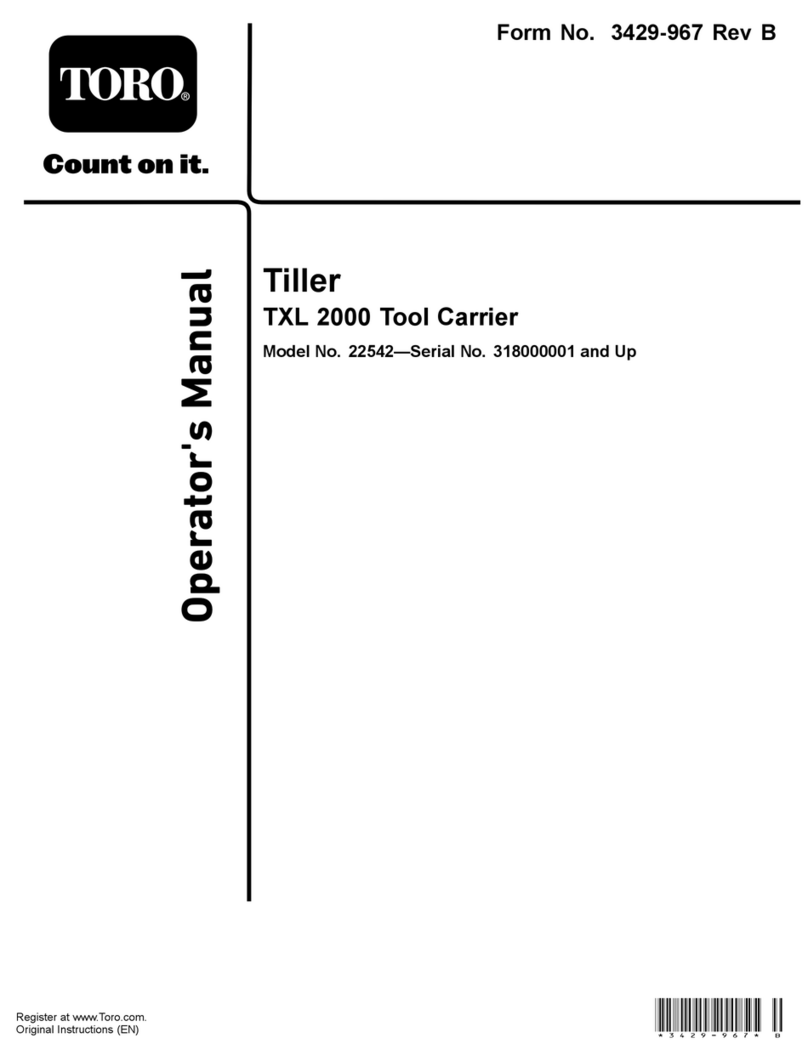

90_

Figure 21

In some instances, angling the aerator forward may

improve hole quality but will also reduce aeration depth

and gain clearance with the turf guards. A forward angle

of approximately 4_is a good initial setting. Use a

magnetic based angle indicator to determine the forward

angle, or use the following procedure:

A. Position aerator on a flat level surface.

B. Make sure aerator roller is on the ground and depth

indicator is set at desired setting (Fig. 22).

1

Figure 22

1. Depth guide

C. Measure and record the distance from the ground

to the lower rear corner of the frame (“H1”) and

front corner of the frame (“H2”) (Fig. 23).

4_

“H1”

“H2”

Figure 23

D. Adjust upper link until the difference between

“H1”–“H2” matches desired forward angle of

aerator (See Angle Chart below).

“H1”–

“H2”

0” 0.8”

(21mm)

1.7”

(43mm)

2.5”

(64mm)

3.3”

(85mm)

Angle 0_2_4_6_8_

This manual suits for next models

5

Table of contents

Other Toro Tiller manuals

Toro

Toro 58602 User manual

Toro

Toro 09802 HydroJect 3010 User manual

Toro

Toro GREENS AERATOR 09120 User manual

Toro

Toro 58604 User manual

Toro

Toro Soil Cultivator User manual

Toro

Toro 23515 User manual

Toro

Toro 23518 User manual

Toro

Toro 23516 User manual

Toro

Toro 22542 User manual

Toro

Toro 58601 User manual

Popular Tiller manuals by other brands

TARAL

TARAL 16M owner's manual

Craftsman

Craftsman Incredi-Pull 316.292621 Operator's manual

Ryobi

Ryobi RY36CVXA manual

Meccanica Benassi

Meccanica Benassi MTC 601 Use and maintenance manual

IVT

IVT GTIL-63R-RC instruction manual

White Outdoor

White Outdoor Roto Boss 850 215-418-190 Parts list and instruction manual