Operating instructions KEA 202 INS - 2 / 22 - File: BA_KEA 202 INS_EN_Ver 2016-07-01.docx

______________________________________________________________________________________

Technische Änderungen vorbehalten

An der Kleinbahn 39, D-21423 Winsen (Luhe)

Telefax: +49 4171-798-117

2. Revision history

Connection diagrams updated. Design and drawing fully renewed

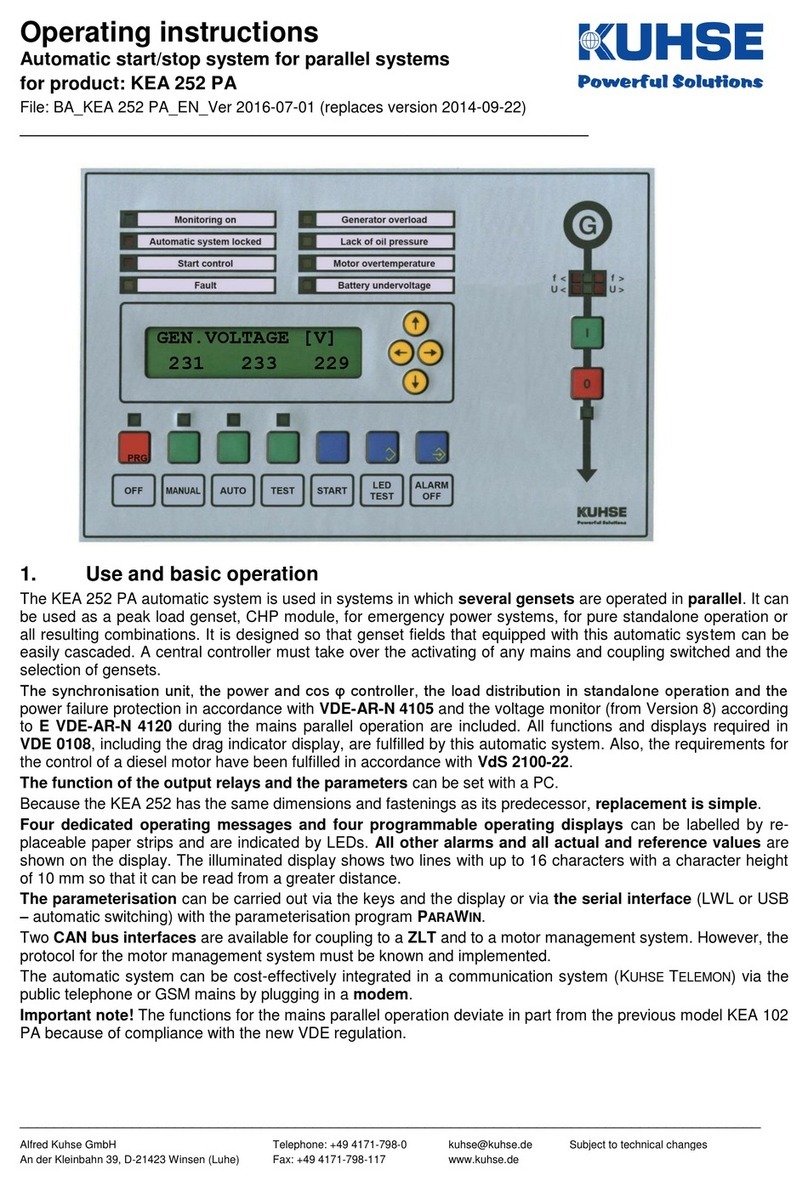

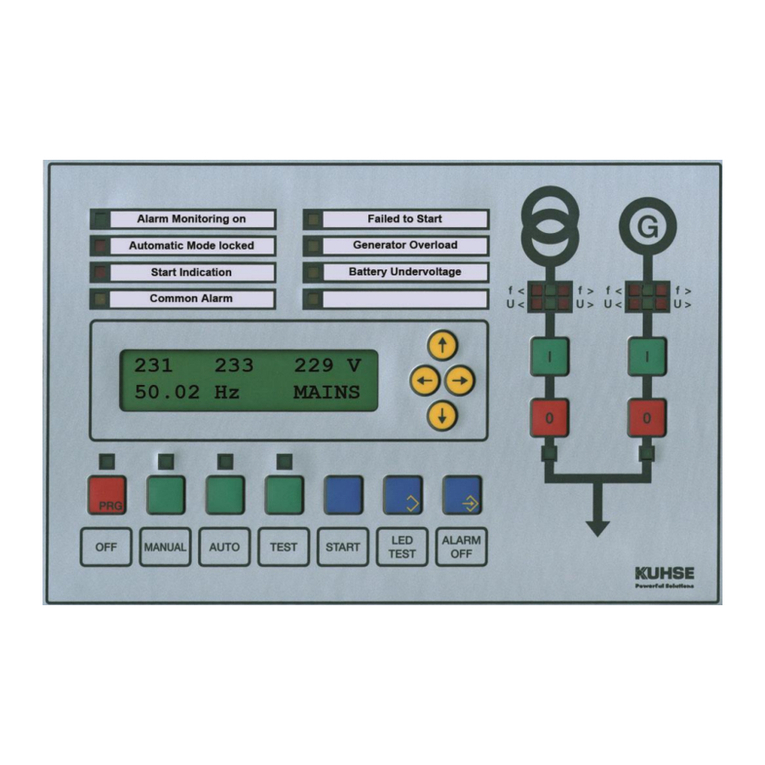

Figures renewed for display and control elements

3. Content

1. Use and basic operation............................................................................................................................ 1

2. Revision history.......................................................................................................................................... 2

3. Content ...................................................................................................................................................... 2

4. Functions ................................................................................................................................................... 4

5. Warnings.................................................................................................................................................... 4

5.1. Regulations and instructions.............................................................................................................. 4

5.2. Installation and commissioning.......................................................................................................... 4

5.3. Connections....................................................................................................................................... 4

5.4. Battery and supply voltage ................................................................................................................ 4

5.5. Coils................................................................................................................................................... 4

6. Basic operation of automatic system......................................................................................................... 5

6.1. Operation of the display..................................................................................................................... 5

6.2. Display contrast setting...................................................................................................................... 5

6.3. Parameterisation................................................................................................................................ 6

6.3.1. Description................................................................................................................................. 6

6.3.2. General parameters, group 0..................................................................................................... 6

7. Display and control elements..................................................................................................................... 7

7.1. Monitoring on..................................................................................................................................... 7

7.2. Automatic system locked................................................................................................................... 7

7.3. Start control........................................................................................................................................ 7

7.4. Fault................................................................................................................................................... 8

7.5. Four programmable displays ............................................................................................................. 8

7.6. Mimic diagram / Voltage monitor ....................................................................................................... 8

7.7. Keys for operating mode.................................................................................................................... 8

7.8. Start key............................................................................................................................................. 8

7.9. LED Test button................................................................................................................................. 9

7.10. Alarm Off button............................................................................................................................. 9

8. Operating modes ....................................................................................................................................... 9

8.1. Controlling the auxiliary drives........................................................................................................... 9

8.2. Off operating mode............................................................................................................................ 9

8.3. Manual operating mode..................................................................................................................... 9

8.3.1. Description................................................................................................................................. 9

8.3.2. Manual speed adjustment.......................................................................................................... 9

8.3.3. Manual voltage adjustment........................................................................................................ 9

8.4. Auto operating mode ....................................................................................................................... 10

8.4.1. Description............................................................................................................................... 10

8.4.2. External start order .................................................................................................................. 10

8.5. Test operating mode........................................................................................................................ 10

9. Sprinkler operation................................................................................................................................... 10

10. Alarm messages.................................................................................................................................. 11

10.1. Display and acknowledgement of alarms.................................................................................... 12

10.2. Description of the alarms............................................................................................................. 12