Manual ELW 170 / ELW 180

May 2020

page 2

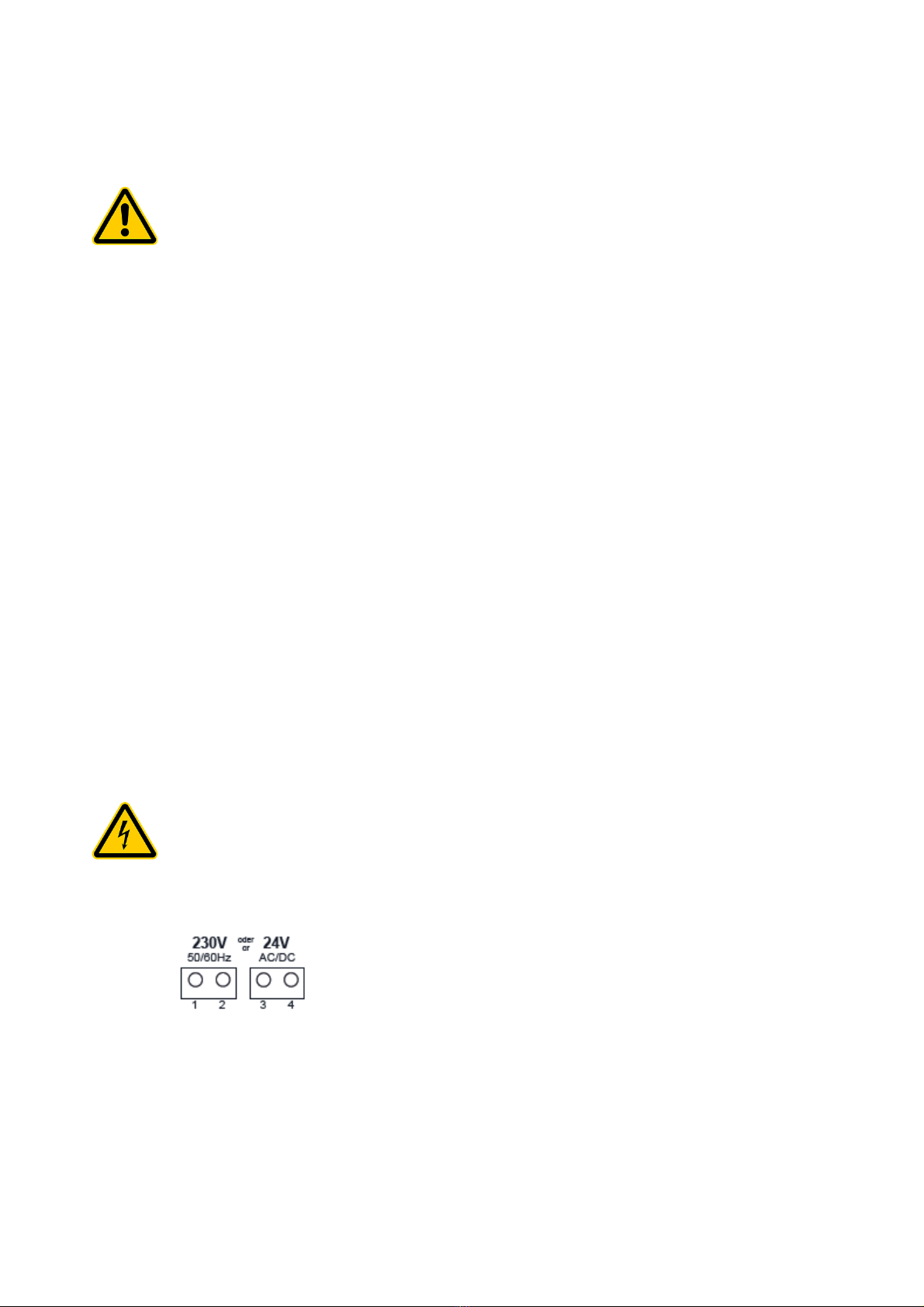

The housing may be opened to be connected to the electricity supply and to set parameters.

There are hazardous circuits inside the housing. The airflow monitor may only be operated

by staff who have been authorised and trained to do so by the system operator.

The applicable standards and directives should be observed.

The EMC directives must be ensured for the entire system.

2. Proper use

The airflow monitors ELW 170 and ELW 180 are only intended for commercial use.

The devices are used for the following purposes:

- To evaluate airflows and the resultant generation of switching statuses.

- For monitoring off ans or butterfly valves

- For use in conjunction with DDC systems

- For flow –dependent monitoring of humidifiers and electric heating coils in accordance with

DIN VDE 0100-420 (Oct. 2019). Please also observe our information S 20.

Proper use also includes the following points:

- The directions provided in these instructions must be noted and followed.

- The technical limit values (see Chapter 6 “Technical data”) must be observed.

- The sensor should only be used to measure air.

- The devices are not suitable for use in areas at risk of explosion or pressurised areas.

The manufacturer accepts no liability for damage resulting from the device not being used properly,

unauthorised modifications to the device, failure to observe these instructions and deployment of

staff who are not qualified. The manufacturer’s guarantee also ceases to apply in such instances.

3. Standards and directives

The device complies with the following requirements:

- 2014/30/EU EMC directive

- 2014/35/EU Low Voltage Directive

- EN 61326-1:2013 General EMC requirements

- EN 61326-2-3:2013 Immunity for residential, commercial and light-industrial environments

- DIN EN 60947-5-1 Low-voltage switchgear and controlgear

- EN 50581:2012 Restriction of hazardous substances

4. Structure of the measurement system

The measurement system comprises the sensor and control unit. The measurement system is available in

two different designs:

- ELW 170 for wall mounting (sensor is connected using a cable)

- ELW 180 for duct mounting (sensor is permanently connected to the control unit)

Sensor and control unit are calibrated independently and, in the version for wall mounting, can be replaced

with identical devices at any time. Sensors and control devices are not compatible with the foreign ELW line.

5. Principle of operation

The airflow monitor works in line with the calorimetric measuring principle where the amount of heat removed

by the airflow is measured and converted into the switching value. In order to do this, the sensor contains a

heating element and 2 temperature sensors. A microcontroller controls the heating and measures differences

in temperature. On the basis of stored calibration curves, it calculates the speed of airflow and transfers the

value to the control unit in a serial manner. Here another microcontroller determines the switching behaviour

of the two relays from the setpoint values for the controller.