Model A

CONTENTS

1. Safety instructions

1.1 safety rules ............................................................................................................ 1

1.2 warning signs ........................................................................................................ 2

1.3 safety position ....................................................................................................... 3

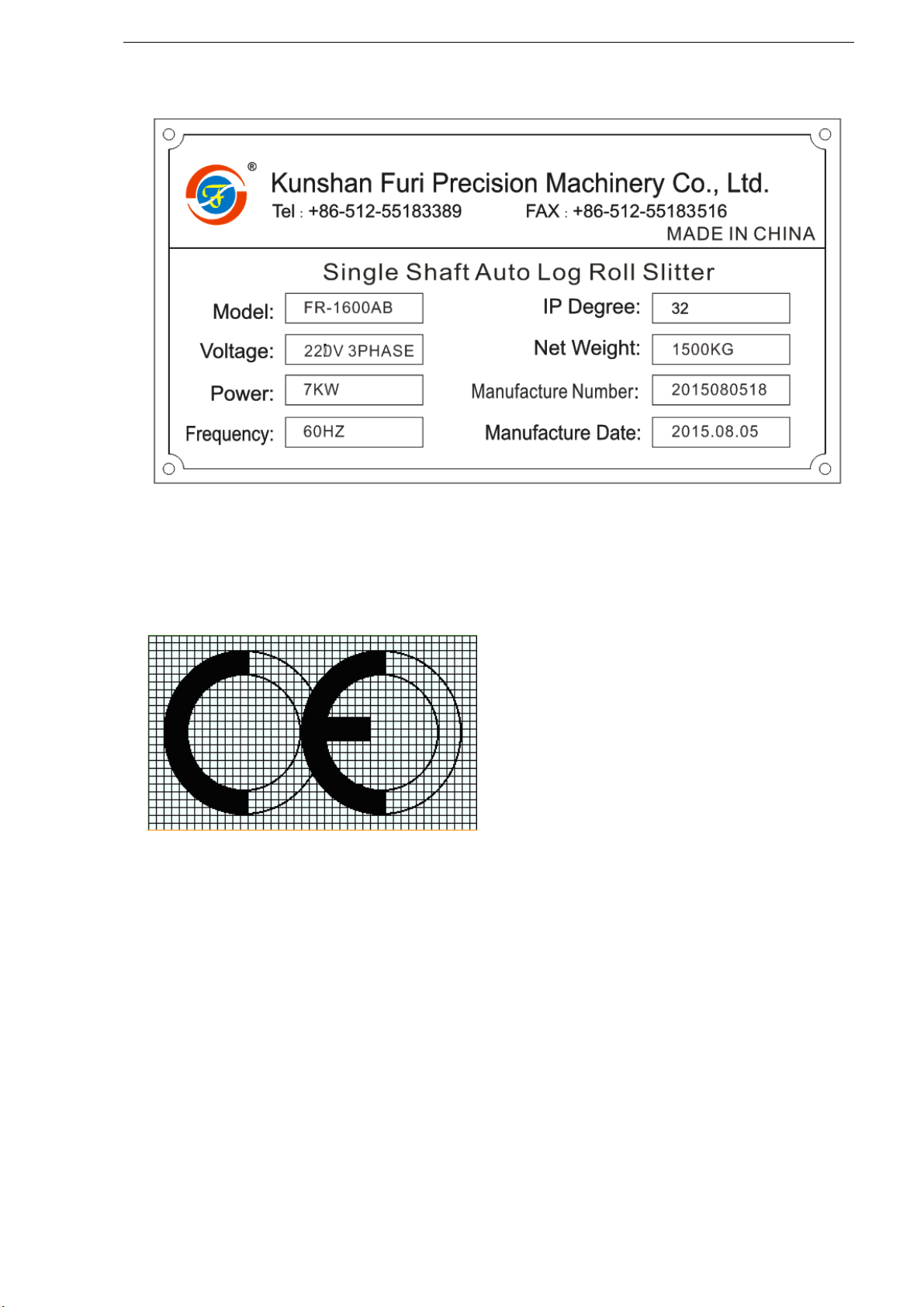

1.4 machine nameplate ................................................................................................ 4

2. Specifications

2.1 specification sheet ................................................................................................. 5

2.2 machine noise level ............................................................................................... 6

2.3 function & feature ................................................................................................. 7

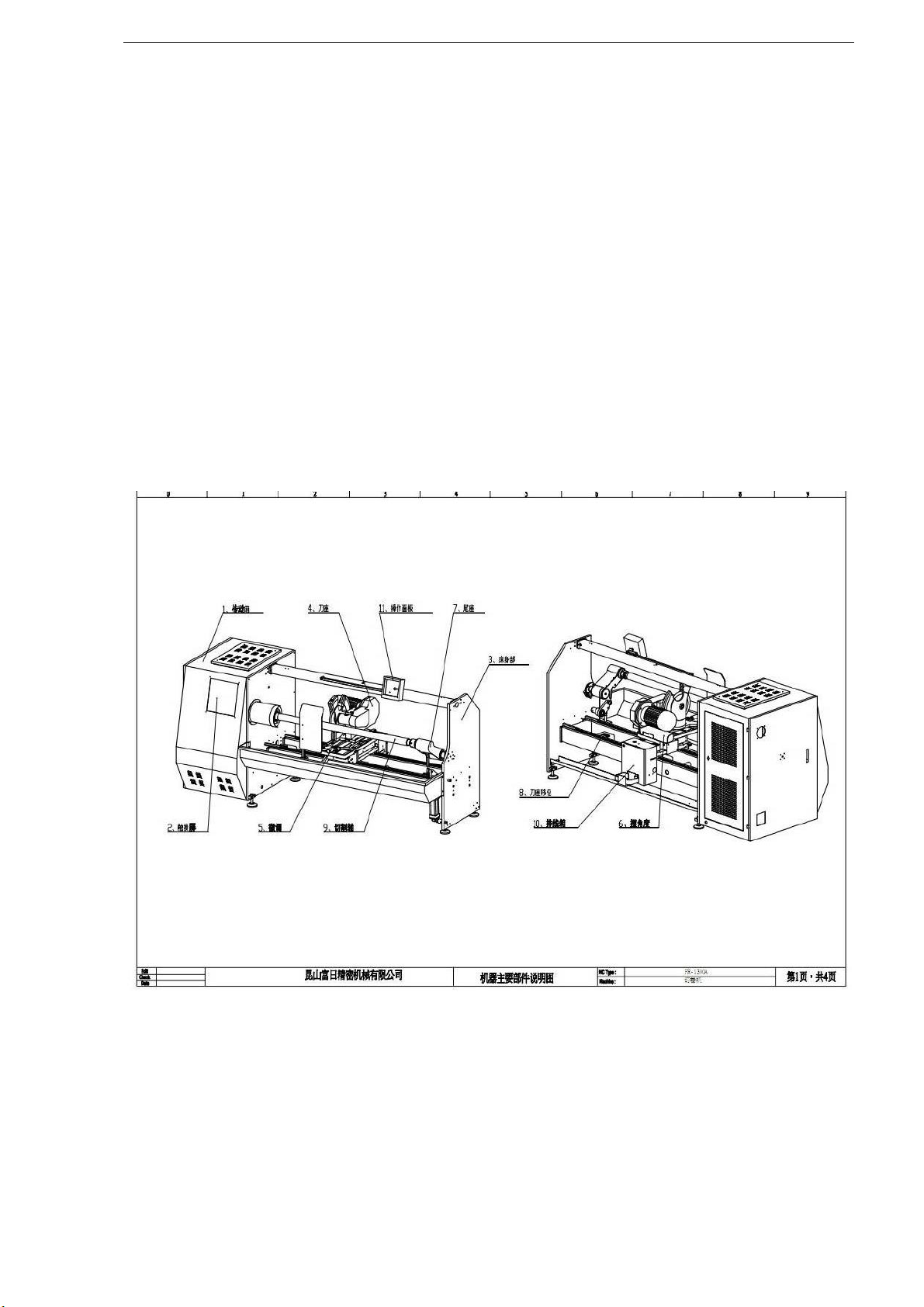

2.4 main parts ............................................................................................................. 8

2.5 machine dimension ............................................................................................... 9

3. Installation

3.1 transportation ....................................................................................................... 10

3.2 transportation method ........................................................................................... 11

3.3 installation site selection ...................................................................................... 12

3.4 installation method ............................................................................................... 13

3.5 leveling installation and adjustment ...................................................................... 14

3.6 power & air source requirement ........................................................................... 15

3.7 gas circuit............................................................................................................. 16

3.8 pneumatic component chart .................................................................................. 17

4. Operation

4.1 operating position ................................................................................................. 18

4.2 operating panel instructions .................................................................................. 19

4.3 emergency stop .................................................................................................... 31

4.4 operating procedure .............................................................................................. 32

4.5 machine adjustment .............................................................................................. 35

5. Maintenance

5.1 machine maintenance ........................................................................................... 42

5.2 machine lubrication .............................................................................................. 44

5.3 breakdown maintenance ....................................................................................... 45

5.4 easy wear parts list ............................................................................................... 45

6. Electric part

6.1 safety rules ........................................................................................................... 46

6.2 circuit diagram ..................................................................................................... 46

6.3 electric components list ........................................................................................ 46

7. After-sales service

7.1 warranty period .................................................................................................... 47

7.2 contact us ............................................................................................................. 47