-14-

English

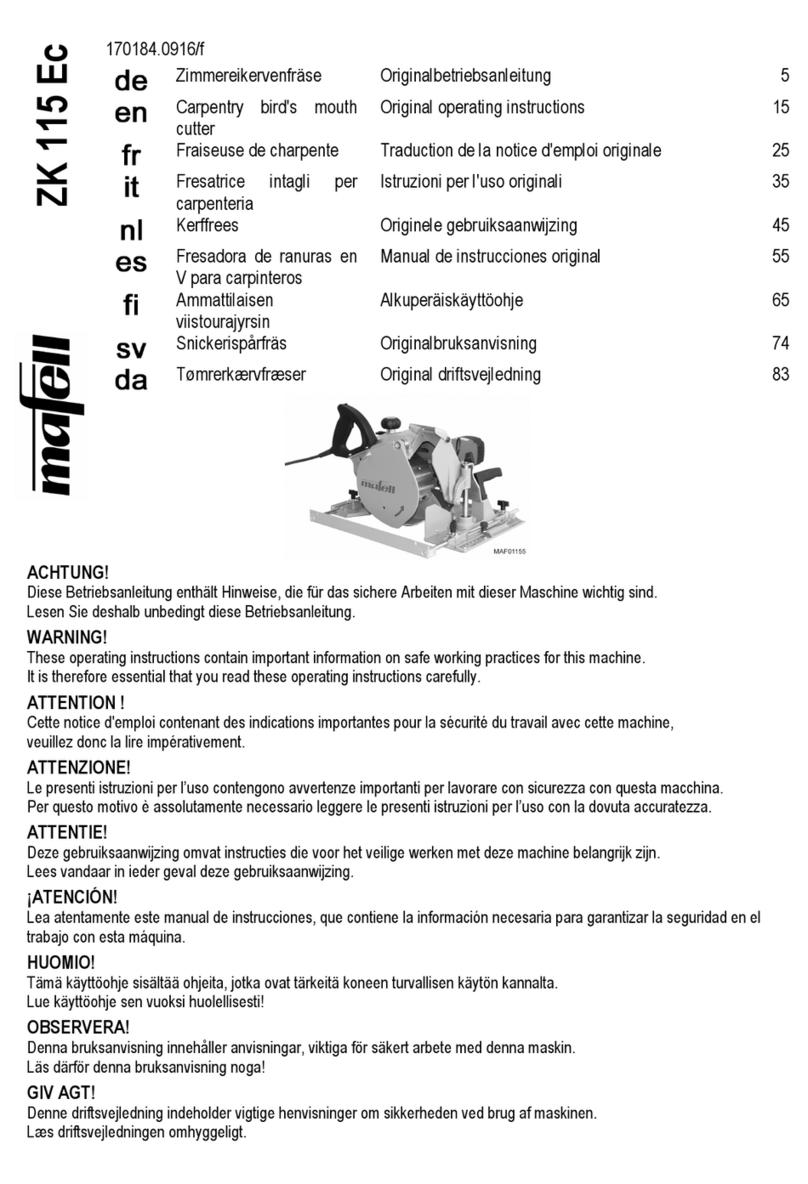

Table of Contents

1 Signs and symbols ......................................................................................................... 15

2 Product information ........................................................................................................ 15

2.1 Manufacturer´s data ....................................................................................................... 15

2.2 Machine identification ..................................................................................................... 15

2.3 Technical data ................................................................................................................ 16

2.4 Emissions ....................................................................................................................... 16

2.5 Scope of supply .............................................................................................................. 16

2.6 Use according to intended purpose ................................................................................ 17

2.7 Residual risks ................................................................................................................. 17

3 Safety instructions .......................................................................................................... 17

4 Setting / Adjustment ....................................................................................................... 18

4.1 Mains connection ........................................................................................................... 18

4.2 Selection of tools ............................................................................................................ 18

4.3 Tool change .................................................................................................................... 19

5 Operation ........................................................................................................................ 19

5.1 Initial operation ............................................................................................................... 19

5.2 Switching on and off ....................................................................................................... 19

5.3 Setting the digging depth ................................................................................................ 20

5.4 Additional limit stop ........................................................................................................ 20

5.5 Collets ............................................................................................................................ 20

5.6 Extraction hood .............................................................................................................. 20

6 Service and maintenance ............................................................................................... 21

6.1 Storage ........................................................................................................................... 21

7 Troubleshooting .............................................................................................................. 21

8 Optional accessories ...................................................................................................... 21

9 Exploded drawing and spare parts list ........................................................................... 21