Table of Contents

8/20/21

© Copyright 2021 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

Trademarks of Great Plains Manufacturing, Inc. include: AccuShot, Max-Chisel, Row-Pro,

Singulator Plus, Short Disk, Swath Command, Terra-Tine, Ultra-Chisel, and X-Press.

Registered Trademarks of Great Plains Manufacturing, Inc. include: Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone,

Nutri-Pro, Seed-Lok, Solid Stand, Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo-Max, Turbo-Till, Ultra-Till, Whirlfilter, and Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

iii

Table of Contents

Important Safety Information . . . . . . . . . . . . . 1

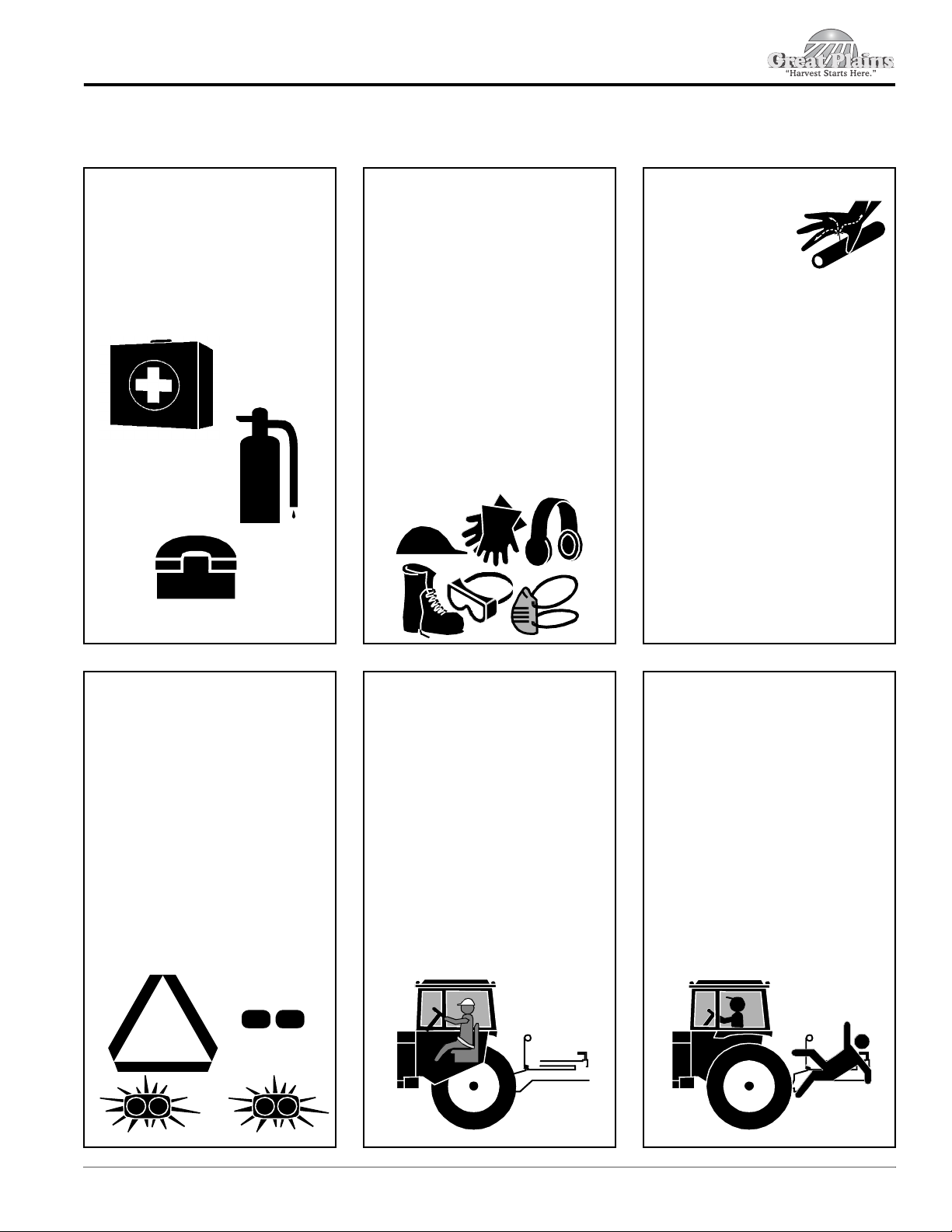

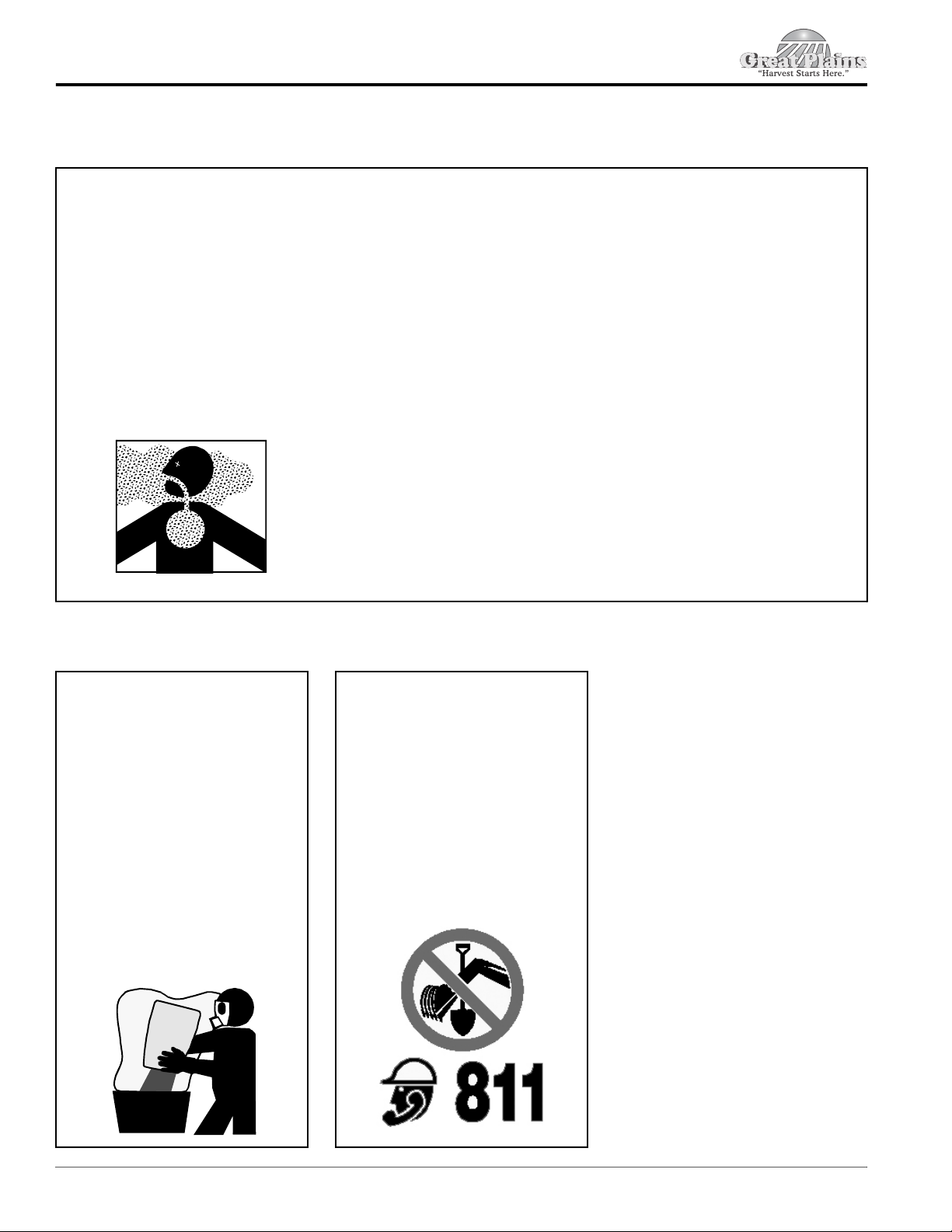

Safety at All Times . . . . . . . . . . . . . . . . . . . . . . . . . 1

Look for the Safety Alert Symbol . . . . . . . . . . . . . . . 1

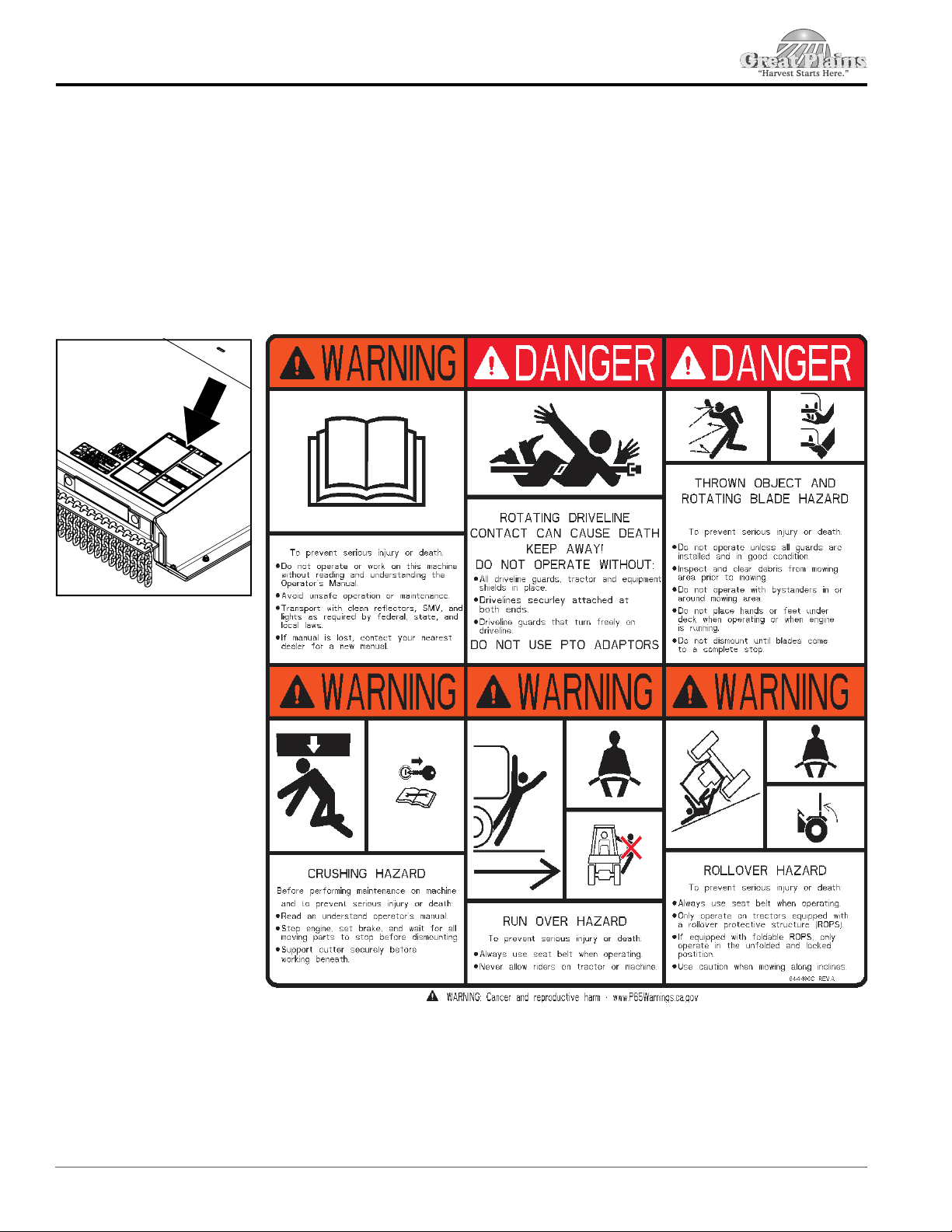

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . 11

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . . 11

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Section 1: Assembly & Set-Up . . . . . . . . . . . 12

Tractor Requirements . . . . . . . . . . . . . . . . . . . . . . 12

Dealer Preparations . . . . . . . . . . . . . . . . . . . . . . . 12

Gearbox Vent Plugs & Dipsticks . . . . . . . . . . . . . . 13

Vented Dipstick Installation . . . . . . . . . . . . . . . . 13

Torque Requirements . . . . . . . . . . . . . . . . . . . . . . 13

Tractor Shutdown Procedure . . . . . . . . . . . . . . . . 13

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3-Point Mounted Rotary Cutter . . . . . . . . . . . . . 13

Semi-Mount Rotary Cutter . . . . . . . . . . . . . . . . . 13

Pull-Type Rotary Cutter . . . . . . . . . . . . . . . . . . . 13

3-Point Assembly & Set-Up . . . . . . . . . . . . . . . . . . 14

Hitch Assembly (3-Point) . . . . . . . . . . . . . . . . . . 14

Spring Hose Loop Assembly (3-Point) . . . . . . . . 15

Driveline Installation (3-Point) . . . . . . . . . . . . . . 15

RCF(M)3696 Tailwheels (3-Point) . . . . . . . . . . . 16

RCF(M)3610 Tailwheels (3-Point) . . . . . . . . . . . 17

RCF(M)3696 Hitch Hook-Up (3-Point) . . . . . . . . 18

RCF(M)3610 Hitch Hook-Up (3-Point) . . . . . . . . 19

Driveline Hook-up (3-Point) . . . . . . . . . . . . . . . . 20

Hydraulic Hook-up Option (3-Point) . . . . . . . . . . 21

Hitch Pin Modification (3-Point & Semi) . . . . . . . 21

Semi-Mount Assembly & Set-Up . . . . . . . . . . . . . . 23

Spring Hose Loop Assembly (Semi-Mount) . . . . 23

Driveline Installation (Semi-Mount) . . . . . . . . . . 23

RCF(M)3696 Tailwheels (Semi-Mount) . . . . . . . 24

RCF(M)3610 Tailwheels (Semi-Mount) . . . . . . . 25

Hitch Hook-Up (Semi-Mount) . . . . . . . . . . . . . . . 26

Driveline Hook-up (Semi-Mount) . . . . . . . . . . . . 27

Hydraulic Hook-up (Semi-Mount) . . . . . . . . . . . . 27

Check Driveline Collapsible Length . . . . . . . . . . . . 28

Assemble Inner & Outer Driveline Halves . . . . . 28

Check Driveline Clearance . . . . . . . . . . . . . . . . . . 29

Pull-Type Assembly & Set-Up . . . . . . . . . . . . . . . . 30

Tailwheel Lift Options . . . . . . . . . . . . . . . . . . . . . 30

Axle Assembly (Pull-Type) . . . . . . . . . . . . . . . . . 30

Spring Hose Loop (Pull-Type) . . . . . . . . . . . . . . 31

Tongue Assembly (Pull-Type) . . . . . . . . . . . . . . 31

Park Jack Assembly (Pull-Type) . . . . . . . . . . . . . 31

Equal Angle Driveline (Pull-Type) . . . . . . . . . . . . 32

Constant Velocity Driveline (Pull-Type) . . . . . . . 33

Hitch Hook-Up (Pull-Type) . . . . . . . . . . . . . . . . . 34

Safety Chain Hook-Up For Pull-Type . . . . . . . . . 35

Hydraulic Hook-Up (Pull-Type) . . . . . . . . . . . . . . 35

Purge Hydraulic System (Pull-Type) . . . . . . . . . 35

Section 2: Assembly of Optional Equipment 36

Chain Safety Guards (Optional) . . . . . . . . . . . . . . 36

Front Chain Guards . . . . . . . . . . . . . . . . . . . . . . 36

Rear Chain Guard . . . . . . . . . . . . . . . . . . . . . . . 36

Rubber Safety Guards (Optional) . . . . . . . . . . . . . 37

Front Rubber Guards . . . . . . . . . . . . . . . . . . . . . 37

Rear Rubber Guard . . . . . . . . . . . . . . . . . . . . . . 37

Pull-Type Hitch Options . . . . . . . . . . . . . . . . . . . . . 38

Swivel Clevis Hitch . . . . . . . . . . . . . . . . . . . . . . . 38

Performance Hitch . . . . . . . . . . . . . . . . . . . . . . . 38

Change Out Hitches . . . . . . . . . . . . . . . . . . . . . . 38

Check Chains (Accessory) . . . . . . . . . . . . . . . . . . 39

Section 3: Adjustments . . . . . . . . . . . . . . . . . 41

Park Jack Angle Alignment . . . . . . . . . . . . . . . . . . 41

Deck Leveling & Height Adjustment . . . . . . . . . . . 42

3-Point With Beam Arms . . . . . . . . . . . . . . . . . . 42

3-Point or Semi-Mount With Rear Axle . . . . . . . . 44

Level Front To Back . . . . . . . . . . . . . . . . . . . . . . 45

Pull-Type With Rear Axle . . . . . . . . . . . . . . . . . . 46

Section 4: Operating Instructions . . . . . . . . . 48

Operating Checklist . . . . . . . . . . . . . . . . . . . . . . . . 48

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . 48

Inspect Tractor & Cutter . . . . . . . . . . . . . . . . . . . . 49

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Blade Engagement & Disengagement . . . . . . . . . . 50

Field Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Crossing Steep Ditches & Banks . . . . . . . . . . . . 51

Turning Angles for Pull-Type Cutters . . . . . . . . . 51

Unhook 3-Point or Semi-Mount . . . . . . . . . . . . . . . 52

Unhook Pull-Type . . . . . . . . . . . . . . . . . . . . . . . . . 53

General Operating Instructions . . . . . . . . . . . . . . . 54

Section 5: Maintenance & Lubrication . . . . . 55

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . 55

Tire Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Cutter Blade Maintenance . . . . . . . . . . . . . . . . . . . 56

Driveline Slip-Clutch . . . . . . . . . . . . . . . . . . . . . . . 58

Flex Couplers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Continue Table of Contents on next page