CASTLE, INC TSM-21 Bosch Motor Carriage Install Page 3 of 25

Table of Contents

1INTRODUCTION.............................................................................................................................4

1.1 DEFINITION OF TERMS................................................................................................................4

1.2 IDENTIFICATION OF OPERATING FEATURES AND CONTROLS .........................................................5

2INSTALLATION INSTRUCTIONS ..................................................................................................6

2.1 SAFETY RULES..........................................................................................................................6

2.2 INVENTORY................................................................................................................................7

3REPLACING THE ROUTER CARRIAGE.......................................................................................8

3.1 REMOVING THE ROUTER STOP PLATE.........................................................................................9

3.2 REMOVING THE PORTER CABLE MOTOR CARRIAGE.....................................................................9

3.3 INSTALL THE NEW BOSCH MOTOR CARRIAGE ............................................................................10

3.4 INSTALL THE NEW ROUTER STOP PLATE ...................................................................................11

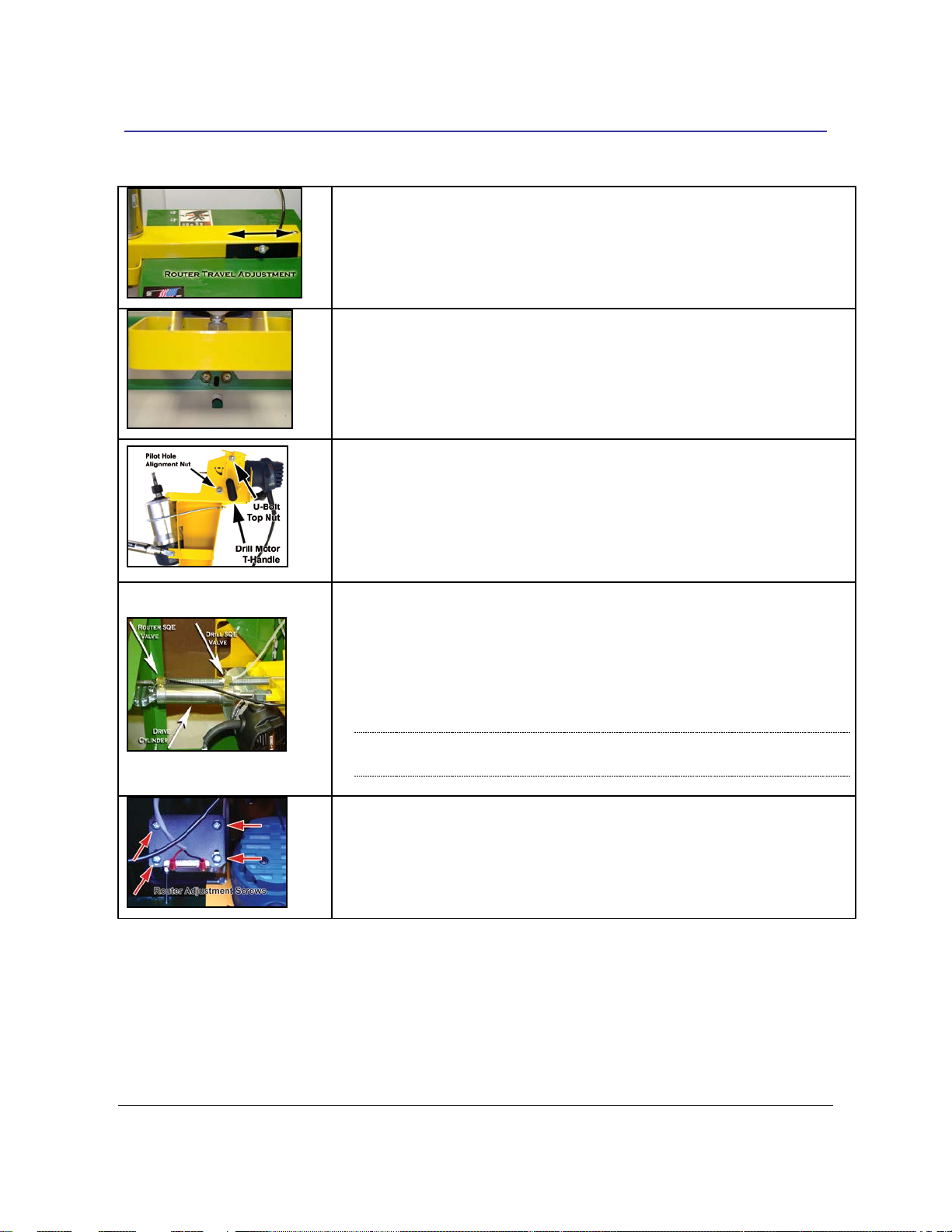

4FINAL INSTALLATION AND ADJUSTMENTS.............................................................................13

4.1 MOTOR REPLACEMENT ............................................................................................................13

4.2 CARRIAGE ADJUSTMENTS ........................................................................................................13

4.3 POCKET WEB ADJUSTMENT......................................................................................................14

4.4 POCKET DEPTH ADJUSTMENT ..................................................................................................15

4.5 DRILL FEED RATE ADJUSTMENT ...............................................................................................16

4.6 PILOT DRILL DEPTH ADJUSTMENT ............................................................................................17

4.7 PILOT DRILL HEIGHT ADJUSTMENT ...........................................................................................18

5SERVICE AND MAINTENANCE ..................................................................................................20

5.1 TOOL CHANGES.......................................................................................................................20

5.2 POCKET ROUTER BIT...............................................................................................................20

5.3 PILOT DRILL BIT.......................................................................................................................22

5.4 GENERAL MACHINE MAINTENANCE...........................................................................................22

5.5 MOTORS AND BITS...................................................................................................................23

5.6 SERIAL NUMBER LOG...............................................................................................................25