3Internal use only

Repair Manual

ESW 308.6

VKS-H

1. Introduction and Safety Instructions

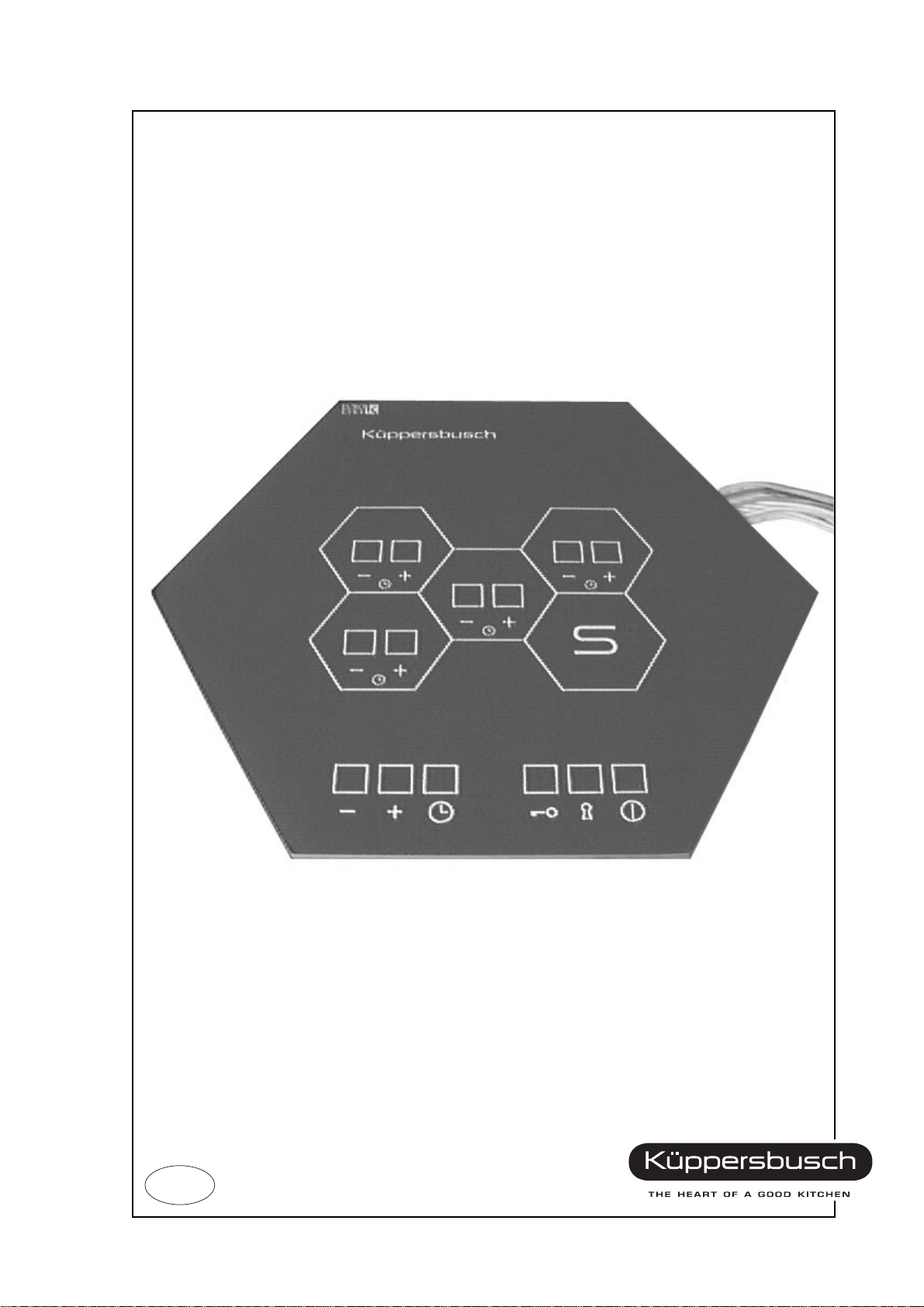

The control honeycomb ESW 308.6 is a sensor-controlled cooking honeycomb

which allows controlling of the cooking zones without contacting them.

In contrast to the forerunning model ESW 307.6, the ESW 308.6 is additionally

equipped with a minute minder. From the outside, however, the functions have

remained identical while the internal structure of the control electronics has

completely changed. With the ESW 308.6 manual balancing of the sensors is no

longer required. The control system will be automatically calibrated upon

commissioning (factory-set). If required, calibration may also be repeated at the

customer. However, it is also possible to manually adjust an individual sensor by

means of a special combination of the sensors. The calibration procedure is

dealt with in detail in a separate chapter.

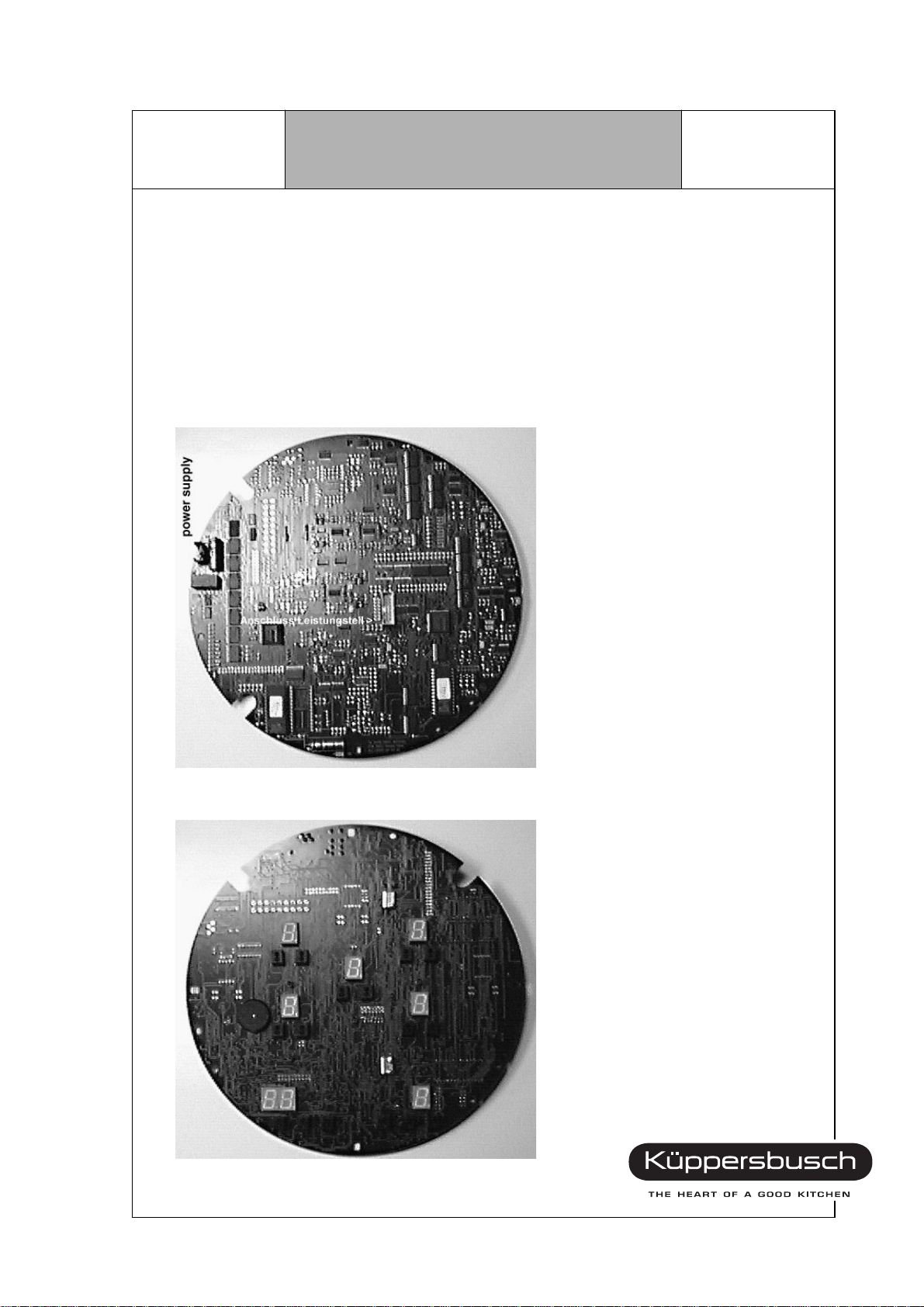

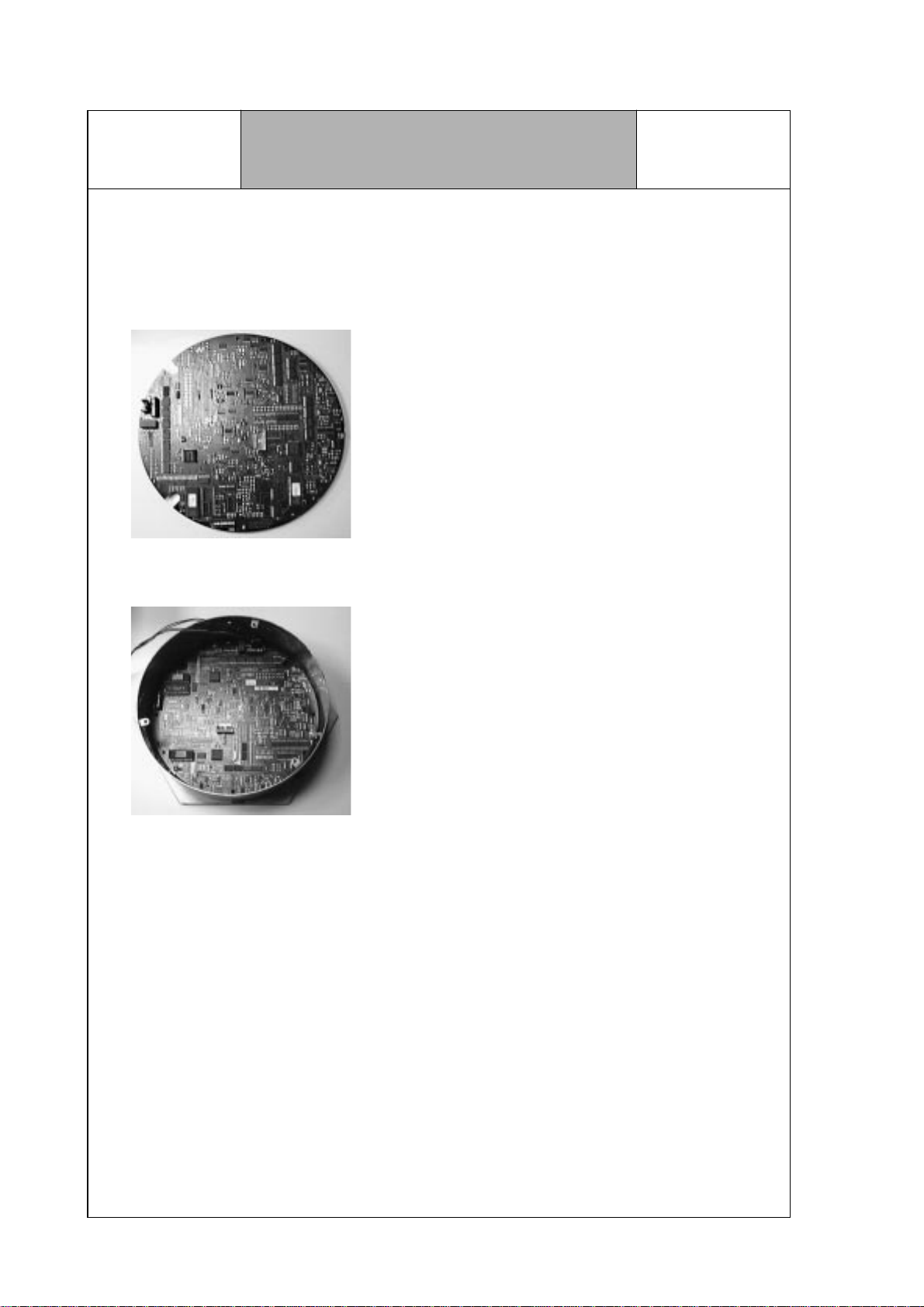

Furthermore, power supply unit and power section of the ESW 308.6 have been

assembled on a joint printed-circuit board mounted on the lid. The connectors

have also been changed.

The appliances are manufactured in accordance with the applicable safety

regulations.

The appliances may only be connected up to the mains, serviced and repaired

by a qualified electrician according to the valid safety regulations. Work carried

out incorrectly will endanger your safety.

When the appliance is connected up to the mains it must be ensured that there

is a device which makes it possible to disconnect it from the mains at all poles

with a contact opening width of at least 3 mm. Line-protecting switches, fuses

and contactors are suitable cut-out devices.

Further general notes are included in the ”Operating and installation instructions

for honeycomb cooking areas with sensor control, series ESW/EKW”.

Before opening the appliance always disconnect it from the power supply!

H1-58-01-02