Nordson EFD 782RA Manual

Other Nordson EFD Control Unit manuals

Nordson EFD

Nordson EFD 745NC User manual

Nordson EFD

Nordson EFD 752V Series Manual

Nordson EFD

Nordson EFD 736HPA Manual

Nordson EFD

Nordson EFD 781Mini Series User manual

Nordson EFD

Nordson EFD 750 Series User manual

Nordson EFD

Nordson EFD 7860C-RS User manual

Nordson EFD

Nordson EFD 741V Series User manual

Nordson EFD

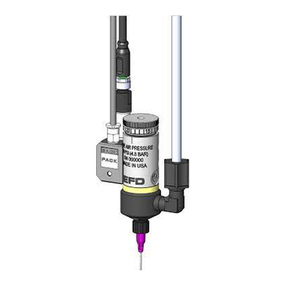

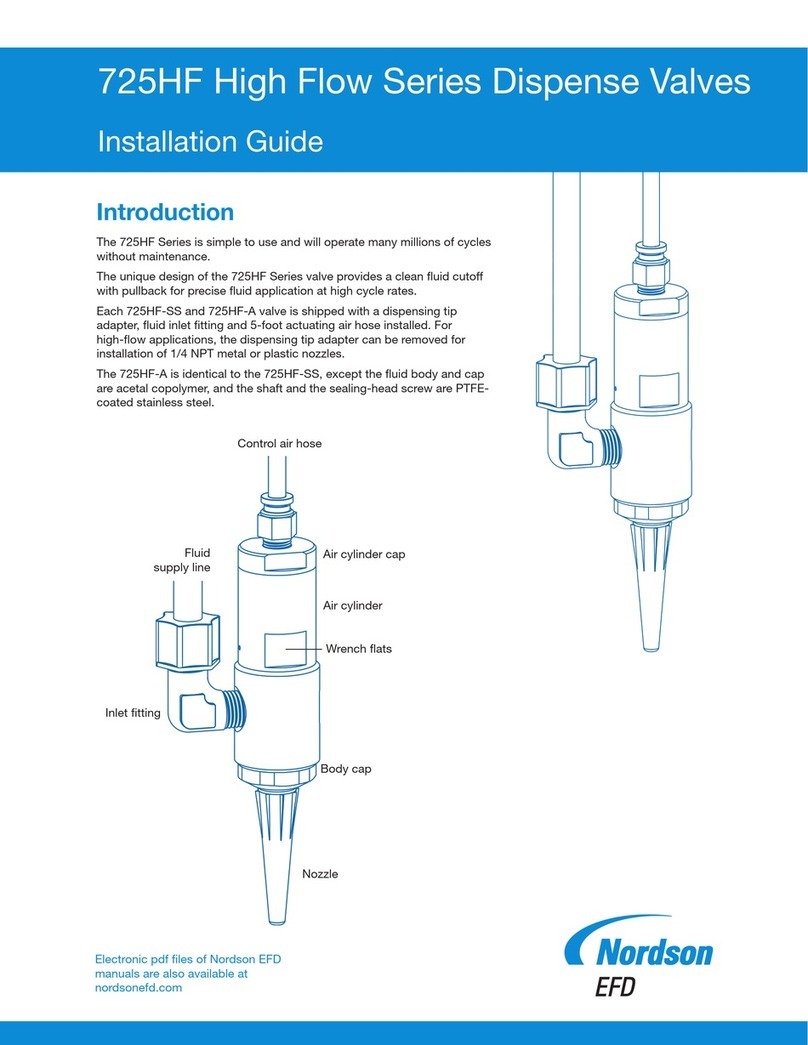

Nordson EFD 725HF User manual

Nordson EFD

Nordson EFD 725HF Series User manual

Nordson EFD

Nordson EFD 750V Manual

Nordson EFD

Nordson EFD 754V-SS User manual

Nordson EFD

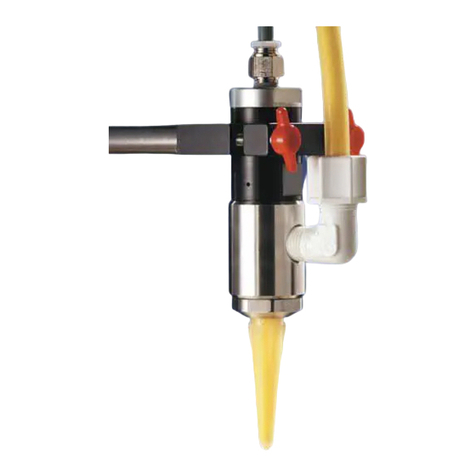

Nordson EFD Liquidyn P-Jet SolderPlus User manual

Nordson EFD

Nordson EFD 725HF-SS Manual

Nordson EFD

Nordson EFD 725HF-SS Manual

Nordson EFD

Nordson EFD 754V-SS Manual

Nordson EFD

Nordson EFD 736HPA-NV Manual

Nordson EFD

Nordson EFD 725DA-SS Manual

Nordson EFD

Nordson EFD 781S Series User manual

Nordson EFD

Nordson EFD 741MD-SS Series User manual

Nordson EFD

Nordson EFD 752V-HL User manual

Popular Control Unit manuals by other brands

National Instruments

National Instruments NI 9221 Getting started guide

Siemens

Siemens SINUMERIK 840D Programming guide

Festo

Festo OVEM-05 operating instructions

SeaSoft

SeaSoft MobilGate - 128d manual

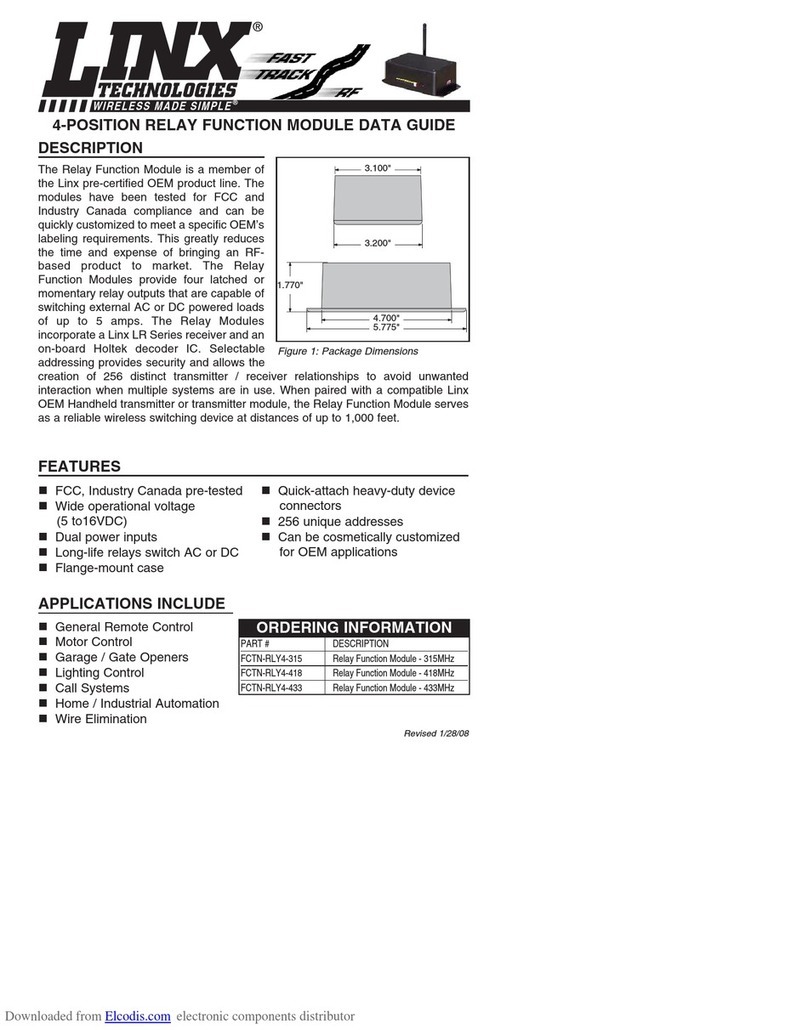

Linx Technologies

Linx Technologies FCTN-RLY4-315 manual

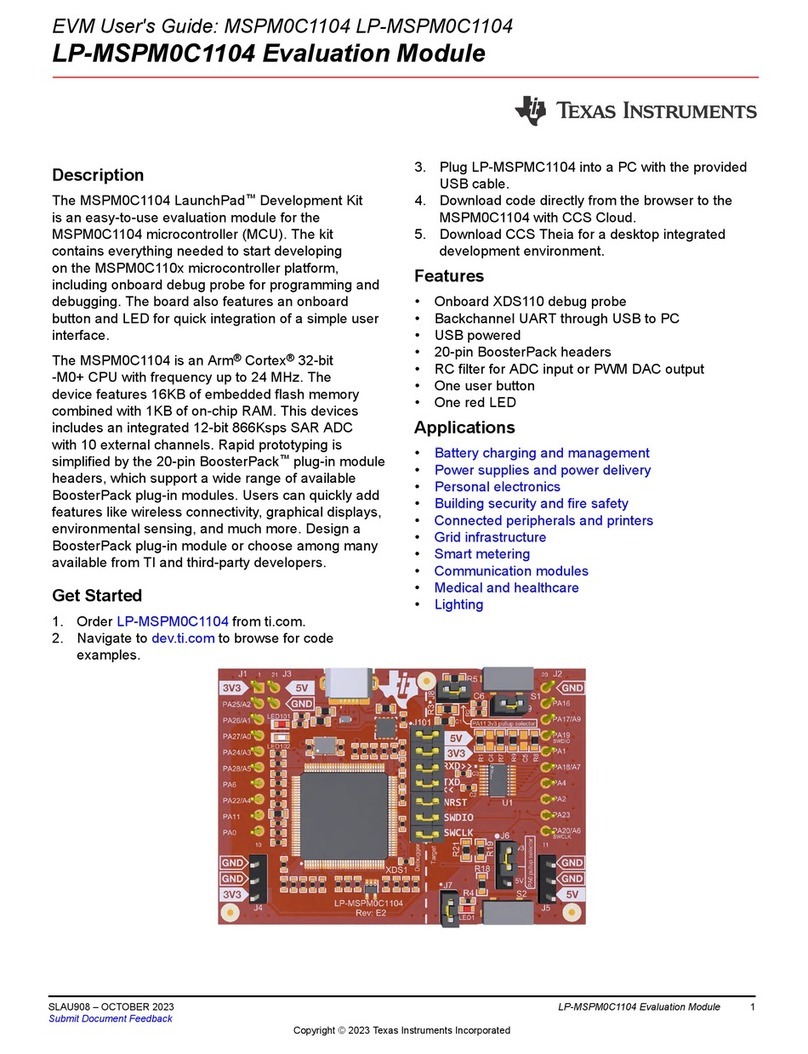

Texas Instruments

Texas Instruments LP-MSPM0C1104 user guide