6 H1-58-01-02-Ä

For internal use only

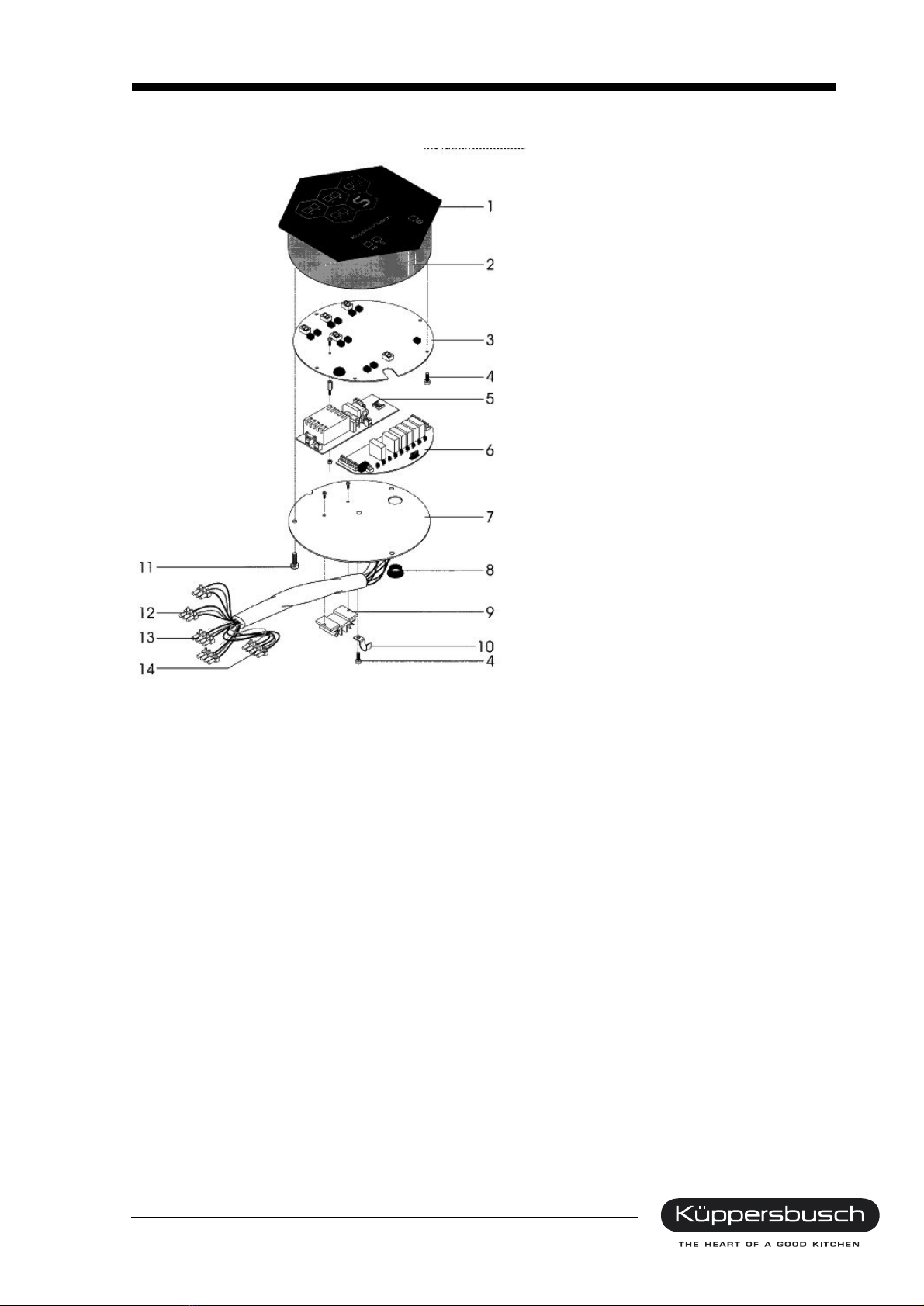

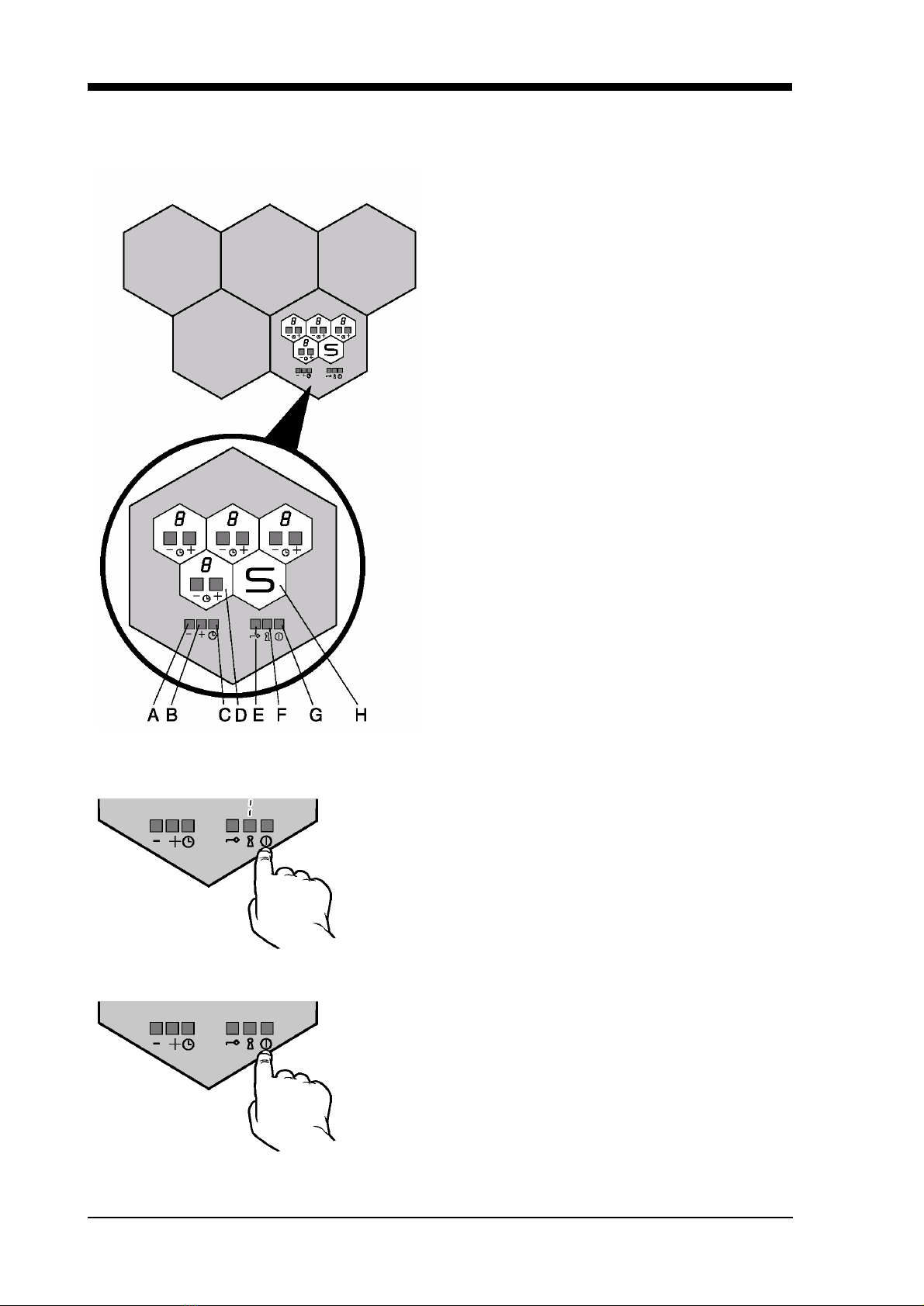

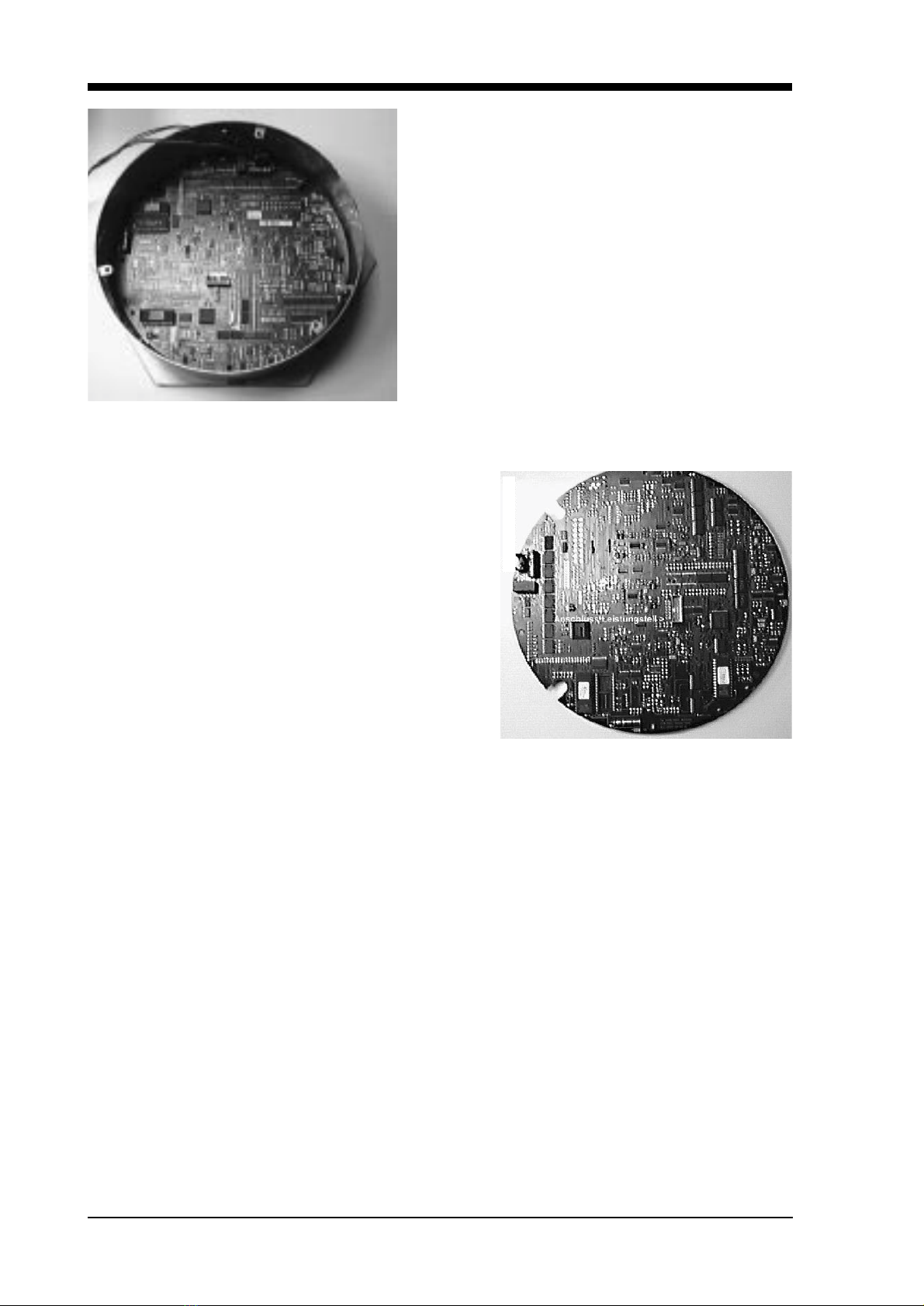

4. Functional Description of the Honeycomb Control Unit

The honeycomb cooking zone is equipped with a

convenient sensor control unit which is regulated by

means of the control honeycomb.

The markings in the honeycomb control unit repeat

the layout of the cooking zones on the worktop.

With the honeycomb control unit you can also

control

• the cooking with auto parboil

• the minute minder

• the childproof lock

The following control fields are on the honeycomb

control unit:

A and B are control fields for the minute minder with

Plus and Minus sensors

C = Minute Minder

D = Control fields for the cooking zones with Plus

and Minus sensors.

E = Key sensor for childproof lock

F = Lock sensor for childproof lock (Sensor-lock).

G = On / Off sensor

H = This field has no control functions. It simply

indicates the position of the honeycomb control unit.

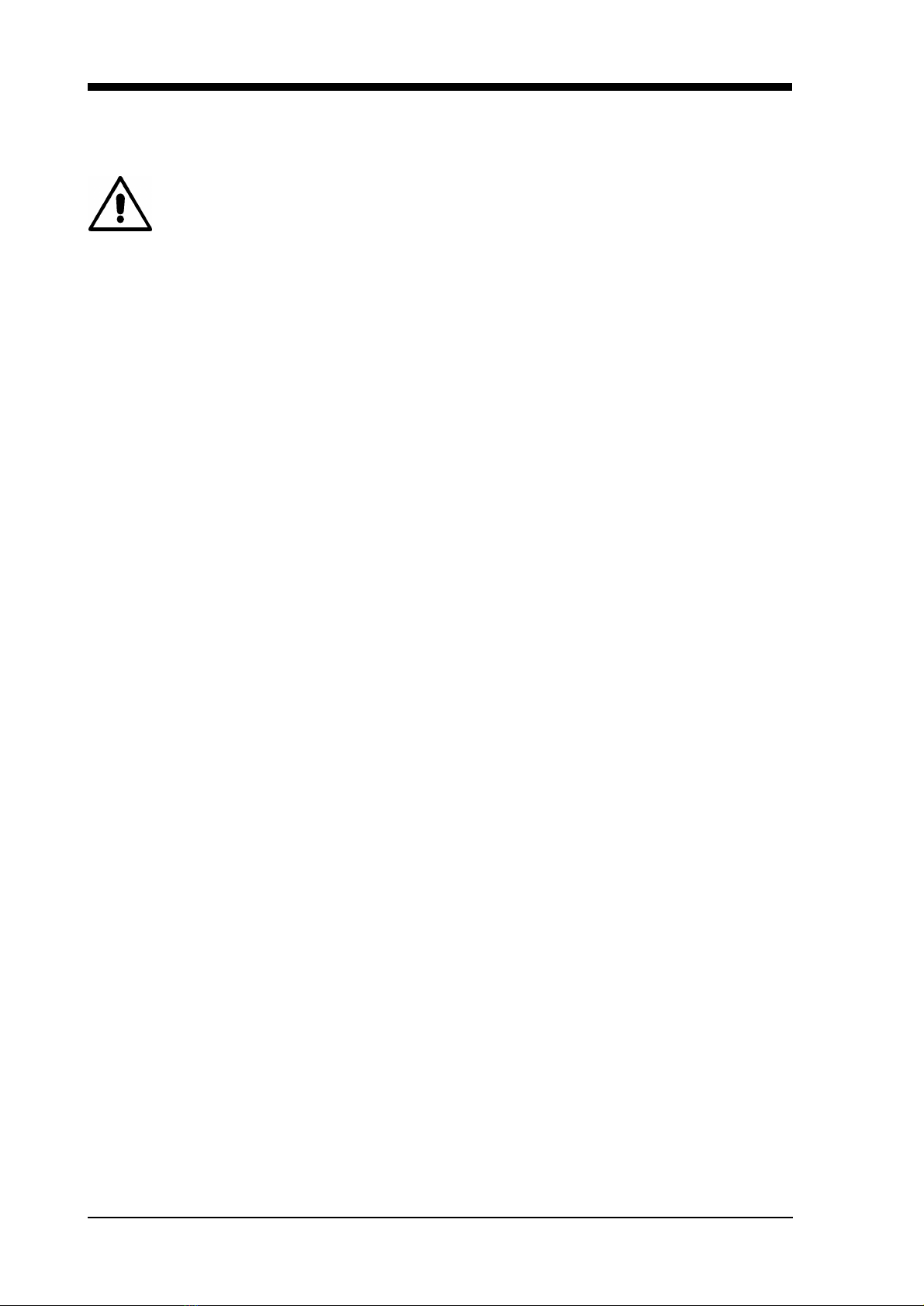

Switching on and off the appliance

Switching on

Touch the ON-OFF sensor for about 2 seconds. A vertical

bar will light up above the lock sensor.

The appliance is now ready to be put into operation (standby

mode). Each cooking zone can now be controlled

individually.

Switching all functions off

Briefly touch the ON-OFF sensor (for about 0.3 seconds).

The vertical bar will be extinguished. The control honeycomb

unit switches off again automatically, if no further sensor is

touched within 20 seconds, if it is left unused for 10 minutes

after operation or if the sensor of a cooking zone is touched

for longer than 20 seconds.

An acoustic signal already sounds after 10 seconds to warn

you that the appliance will switch off after another

10 seconds.

2 secs.

0.3 sec.