Electrical inlet is indicated with a label on the device.

If the device will be used in a commercial kitchen, apply a correct grounding system. Here, consider

DIN VDE D100 Article 540.

The device must be grounded. Grounding point is marked with " ".

OPERATOR INSTRUCTIONS

WARNINGS

Pay attention not to contact hot surfaces of the device!

Device is designed for professional use and must be used only by person who are trained for this

intention.

Device is intended for cooking, do not use for another purpose.

If there is any failure in the device, disconnect electrical power by deactivating the main switch.

Commission only authorized services for maintenance and use genuine spare parts.

Before starting to use the device, carefully clean the surfaces especially those to be in contact with

foods.

During first operation, device will emit fume and smell for a short period. This fume and smell is the

result of the insulation material and the substances such as oil, etc. on the metal sheet surfaces. This is

not dangerous and will disappear by itself.

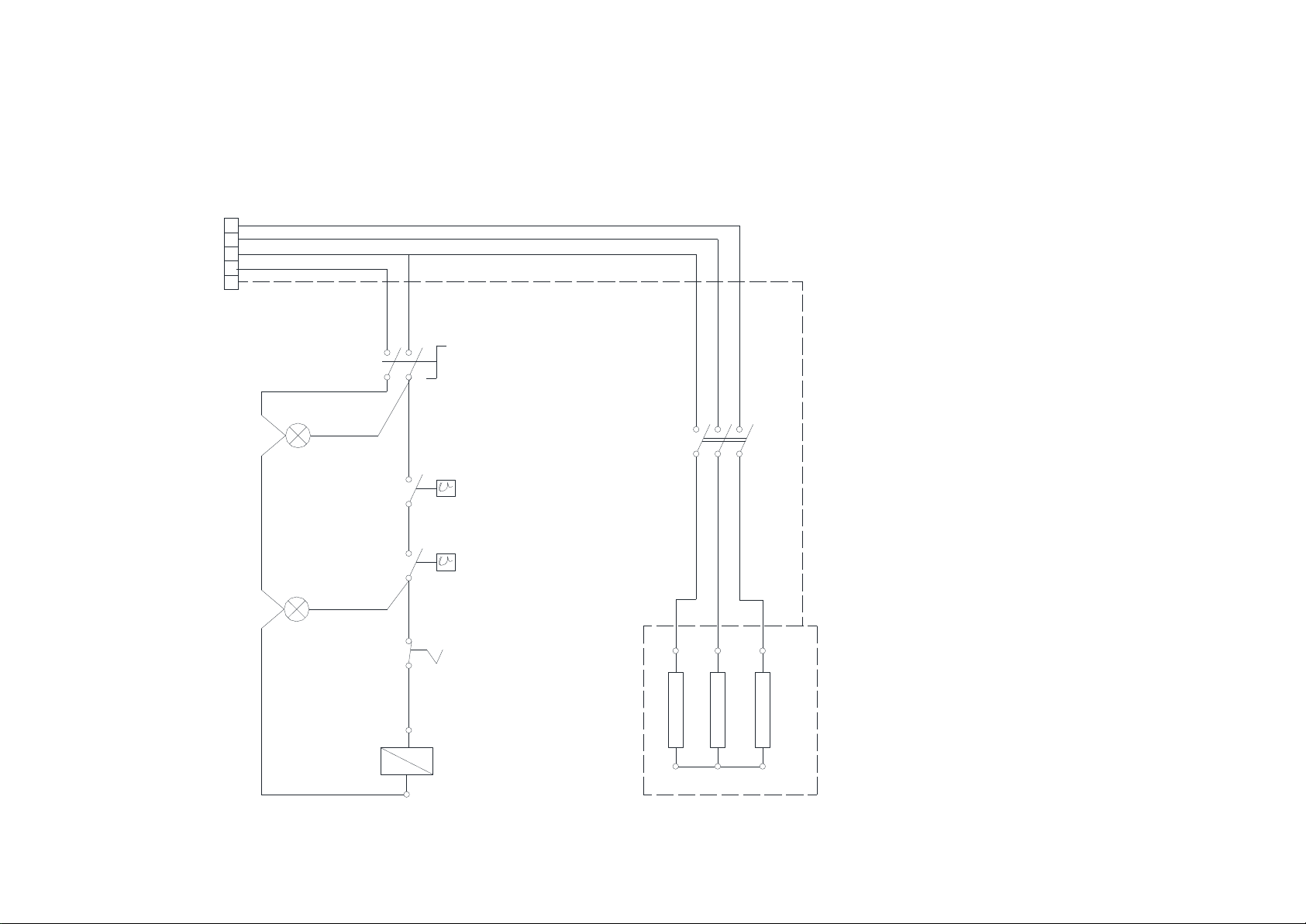

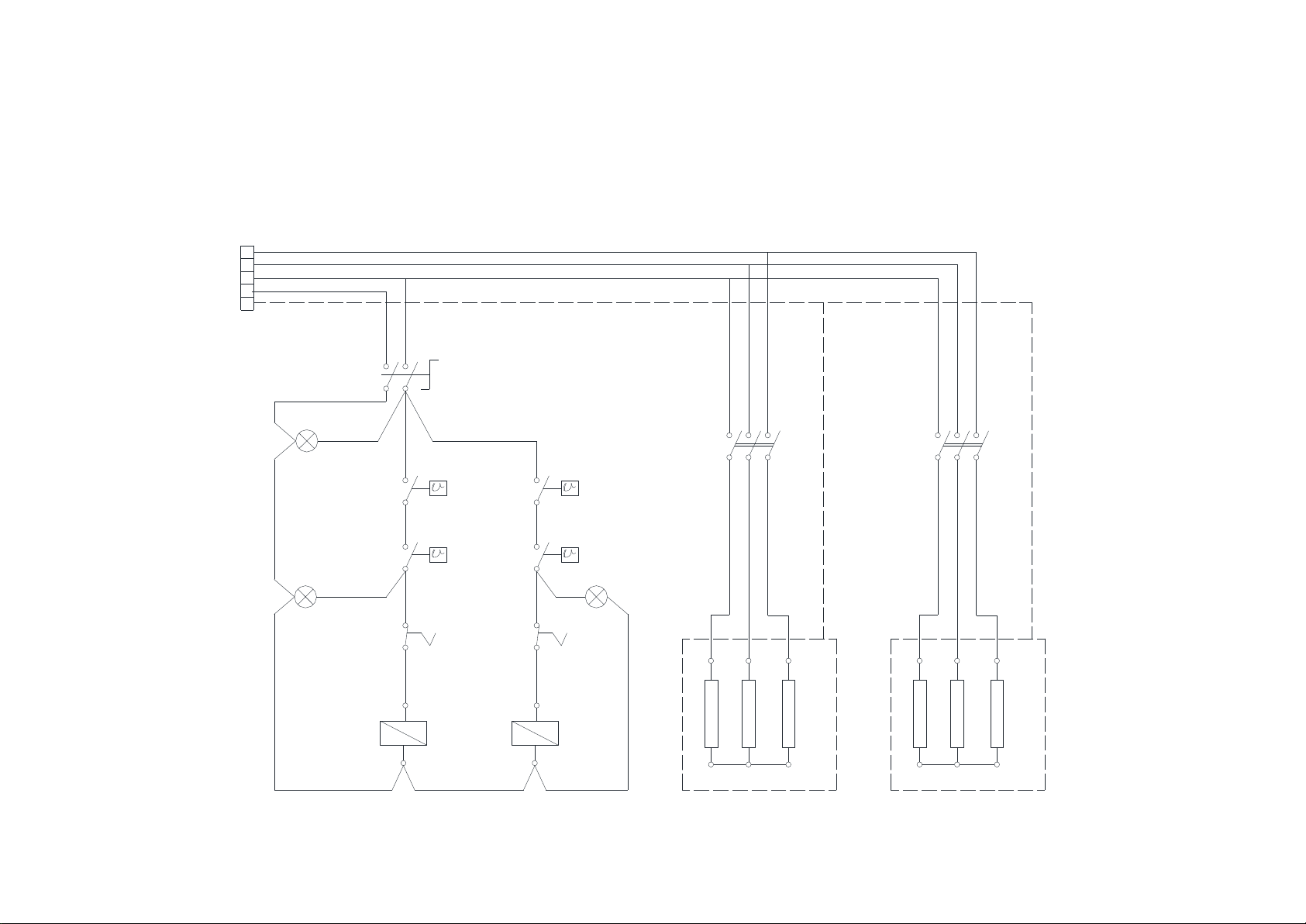

Do not operate the device without oil or under minimum level (Figure B)

Before filling oil, close discharge valve.

Fill oil up to the maximum level prior to put into operation.

Replace frying oil with certain intervals before its properties are lost. Thus, you prevent also burned and

carbonized residue accumulation on heater and chamber surface.

Refill oil when it descends to minimum level. Minimum and maximum oil levels are marked on oil

container. (Figure B)

Do not place foods without draining their water, or foods with solid ice parts.

Rise up the movable headed heater group (4) through its lever to allow cleaning. Afterwards, you should

side-shift support latch (5) to take down it again. (Figure C)

MAINTENANCE

Do not perform maintenance when the device is hot and loaded with electrical power.

Before it cools down completely, wipe the device with a cloth immersed in warm soapy water.

Firstly fill in water and boil to clean oil chamber. This will help cleaning the concrete and sticky oils

easily. Discharge assembly will also be cleaned.

Do not use cleaning substances and tools that may cause scratches on device surface.

If required, use chemical cleaners.

Do not clean the device with water or vapour pressure. Otherwise, you may cause electrical installation

failure.

If the device will not be used for a long period, coat the surfaces with a thin layer of Vaseline.

In case of any dangerous condition with the device, notify to the authorized service. Never let

unauthorized people to interfere in the device.

START-UP(Figure D)

Turn switch a “6” to position “1”.

Adjust thermostat “7” to desired temperature.

When signal light “8” is off, the oil reaches to desired temperature. You can now start to cook.

TURNING OFF (Figure D)

Turn thermostat “6” to position “O”.

Turn switch a “7” to position “O”.