ATS-380 Automatic Transfer Switch

______________________________________________________________________________________

3

SECTION 1 : INTRODUCTION

1.1 Preliminary Comments and Safety

Precautions

This technical document is intended to cover most

aspects associated with the installation, application,

operation and maintenance of the ATS-380

Automatic Transfer Switch Controller. It is provided

as a guide for authorized and qualified personnel

application of the ATS-380 Automatic Transfer

Switch Controller.

1.2 Overview

Transfer switches are used to protect critical

electrical loads against loss of power. The load's

normal power source is backed up by a standby

(emergency) power source. A transfer switch is

connected to both the normal and emergency

sources and supplies the load with power from one

of these two sources. In the event that power is lost

from the normal source, the transfer switch transfers

the load to the standby source. Once normal power

is restored, the load was transferred back to the

normal power source.

When using the ATS-380 module in automatic

transfer switch equipment, the switch's intelligence

system initiates the transfer when normal power

falls below or over a preset voltage or frequency. If

the emergency source is a standby generator, the

transfer switch initiates generator starting and

transfers to the standby source when sufficient

generator voltage and frequency is available. When

normal power is restored, the transfer switch

automatically transfers back and initiates engine

shutdown after a preset engine cooling down time

delay.

An automatic transfer switch consists of three basic

elements:

1. Main contacts to connect and disconnect the load

to the source of power.

2. A transfer mechanism to affect the transfer of the

main contacts from one source to another source.

3. Intelligence control unit to constantly monitor the

condition of the power sources and thus provide

the intelligence necessary for the switch and

related circuit operation.

This manual deals with the third basic element of

the automatic transfer switch, the required

intelligence automatic control module. All the

Automatic Transfer Switch functions were

performed by a door mounted logic panel ATS-380

control unit. The ATS-380 logic panel brings

intelligence, supervisory and programmable

capabilities to automatic transfer switch equipment.

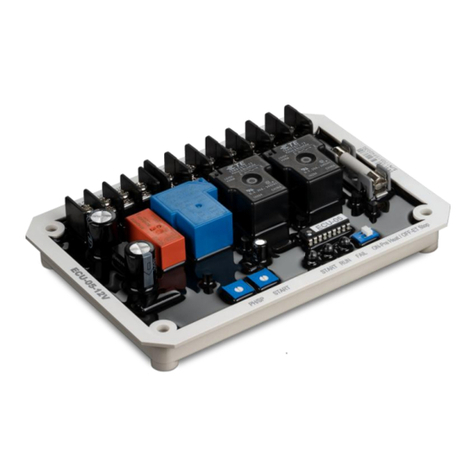

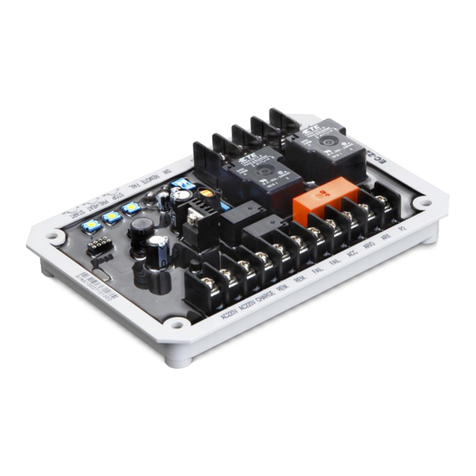

1.3 Product Overview

The ATS-380 Automatic Transfer Switch control

module is an intelligence, comprehensive,

multi-function, microprocessor based automatic

transfer switch controller. It is a compact panel

mounted device designed to replace traditional relay

and solid state logic panels and meet the needs of

markets worldwide.

The ATS-380 controller provides an unmatched

degree of programmed flexibility to address the

needs of most switches system. It can be

programmed for 3Ø and 1Ø system operation.

( Refer to program line 2.)

The ATS-380 controller provides the necessary

intelligence to insure that the switch operates

properly through a series of programmed sensing

and timing functions. The ATS-380 controller will :

●Monitor Normal and Standby source over and

under voltages.

●Monitor Normal and Standby source over and

under frequencies.

●Permit customer programming display real time

information.

●Permit customer programming cyclic mode or fix

mode display for 3 phase voltages and frequency.

( Refer to program line 29.)

●Permit system testing the transfer switch

with/without load from front panel. ( Refer to

program line 4.)

●Store customer / factory established parameters

in memory without losing.