___________________________________________________________________________________________

GCU-100 9

To set the MPU frequency, start the engine in

MANUAL and manually set the engine to 50 Hz or 60

Hz, then quickly press PEN, UP and DOWN arrow

simultaneously for 4 seconds until the word (SAVE)

appears on the display screen.

If the control sees a erroneous frequency reading from

the MPU that Is. below 100 or above 10K Hz, the

control deduces it as an MPU failure and will splay

(FAIL) on the screen and at the same time light up the

warning LED. Check the MPU for incorrect wiring or

bad connections, and after correcting the problem,

repeat the previous steps to finish setting up the MPU.

Any the previous frequency settings are unaffected.

FUNCTIONs

AMPs

31

L

12

L

23

L

3

2

L

1

L

L

V

VOLTs

ALARM

FUNCTIONs

AMPs

31

L

12

L

23

L

3

2

L

1

L

L

V

VOLTs

ALARM

Some electronics speed controllers “Governors” do not

share the MPU with other devices, so you may have to

install another (MPU) or use a dual coil MPU with the

GCU-100. When the control cannot read the frequency

correctly, the GCU-100 shuts down the engine and the

MPU failure icon lights up on the panel.

For MPU settings refer to programming, lines (2), (16),

(17), (18), (19), (21), (22), (23).

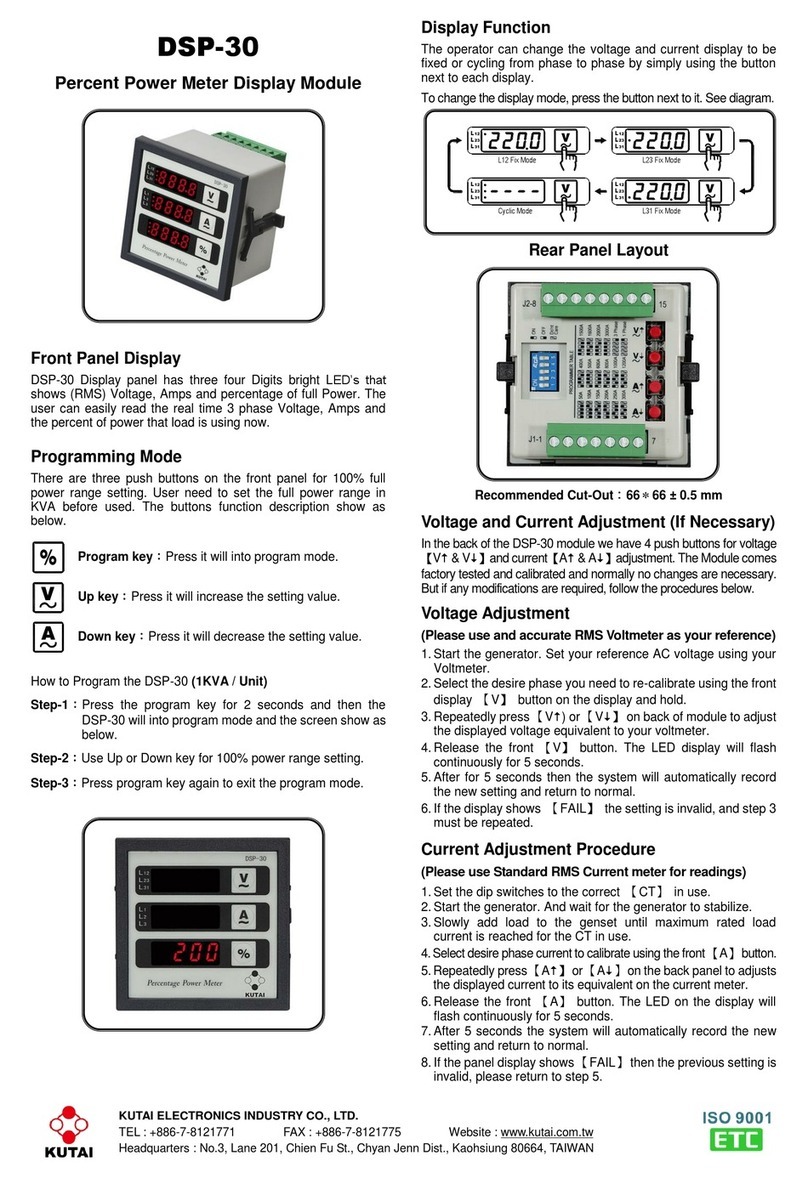

4.4 Setting the AC Voltage and Current Display

In normal operation, you can read full phase voltage

and current directly off the screen. This reading is

factory calibrated. However, if the gen-set encounters

capacitive or inductive loads, waveform distortion

causes minor voltage differences with a calibrated

voltmeter.

If you want an identical reading, you need to

re-calibrate the control AC voltage and current settings.

Once the new calibration is completed, the voltage

reading is identical to the display. The over, under

voltage and load current protection will use these new

values as the system’s reference voltage.

For AC voltage and current display, settings go to

system setting and programming lines (3), (4), (10),

(11).

4.5 Setting AC Voltage Protection

The module comes preprogrammed for AC over and

under voltage protection. However if defective AC

Voltage is detected, it activates a permissive timer to

give the generator time to recover. However if it does

not recover on time, the module activates the AC

voltage protection shutdown showing the abnormal

voltage on the display and lighting up the high or low

AC Voltage LED on the control panel. If the voltage

recovers within the permissive count down, the control

automatically omits the abnormality.

The GCU-100 has two types of protections; a simple

warning and a total engine shutdown.

●Engine Shutdown:perform an immediate engine

power failure, displaying the abnormal reading on

the screen, and lighting up the appropriate a LED

indicator.

●Generator Warning:display the abnormal reading on

the screen and lighting up the appropriate a

universal indicator without stopping the generator.

For AC voltage protection and settings refer to system

programming lines (5), (6), (7), (8), (9).

4.6 Engine Over-load Protection Setting

To prevent inappropriate load usage and causing

gen-set failure and damage, the module is equipped

with engine over-load protection function. User needs

to setup appropriate over load protection setting

according to the gen-set maximum output.

If the system detects engine overload, it automatically

starts engine over-load timer countdown. If rated load

usage does not recover within the countdown, the

system automatically executes engine over-load

protection and displays a failure signal on the panel

and at the same time provides corresponding failure

signal output. If rated load usage is resumed within the

countdown timer, then it automatically omits the

overload warning.