19

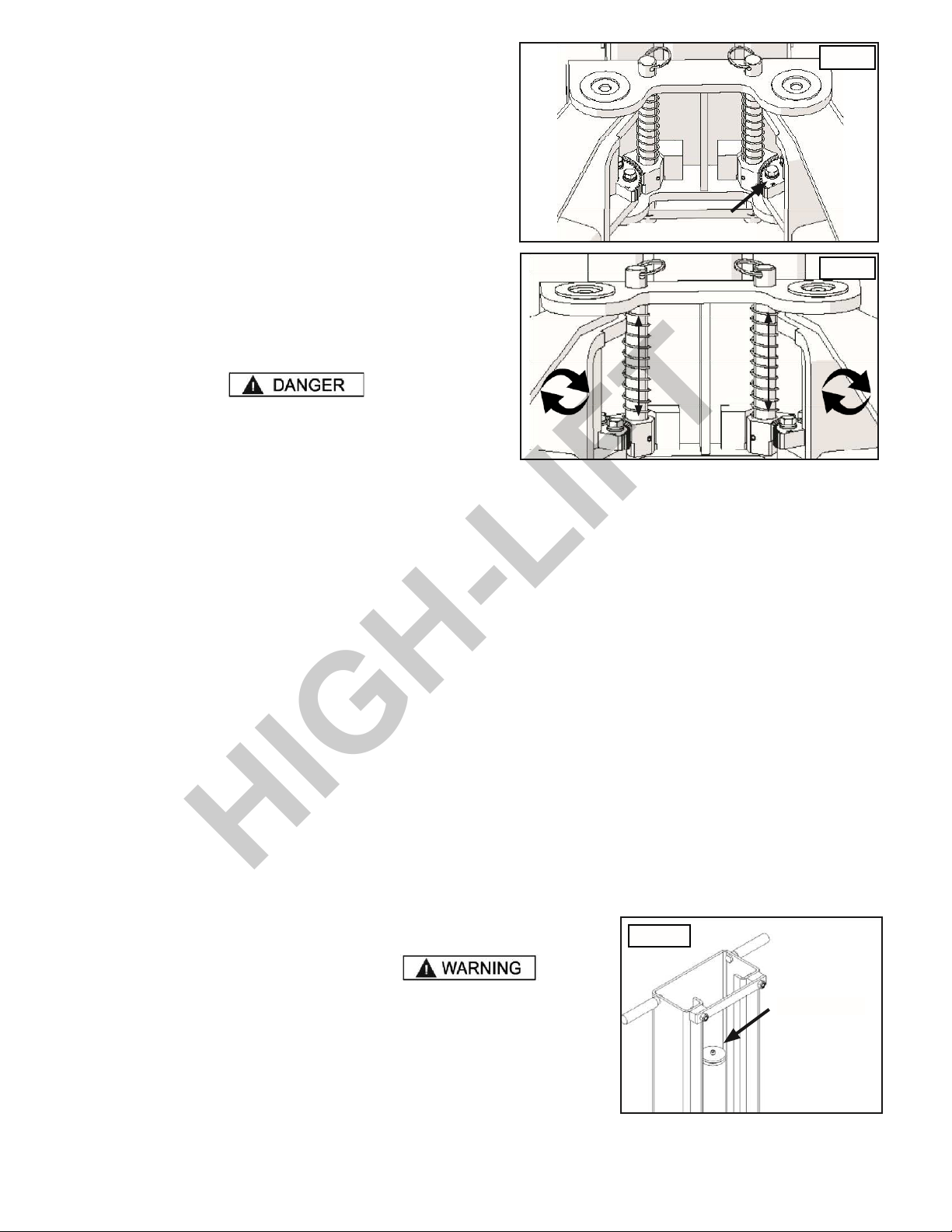

DO NOT use lift if an unlevel lifting condition occurs at the arm pad locations that is greater than 3.5"(89mm). If an

unbalanced condition occurs, follow the bleeding instructions shown on this page or consult Technical Support. The lift

must be re-leveled, shimmed and bled each time the lift is reinstalled. Failure to follow these instructions can result in

serious injury or death.

STEP 12

LIFT START UP / FINAL ADJUSTMENTS

DURING THE START-UP PROCEDURE, OBSERVE ALL OPERATING COMPONENTS AND CHECK FOR PROPER

INSTALLATION AND ADJUSTMENT. DO NOT ATTEMPT TO RAISE VEHICLE UNTIL A THOROUGH OPERATIONAL

CHECK HAS BEEN COMPLETED.

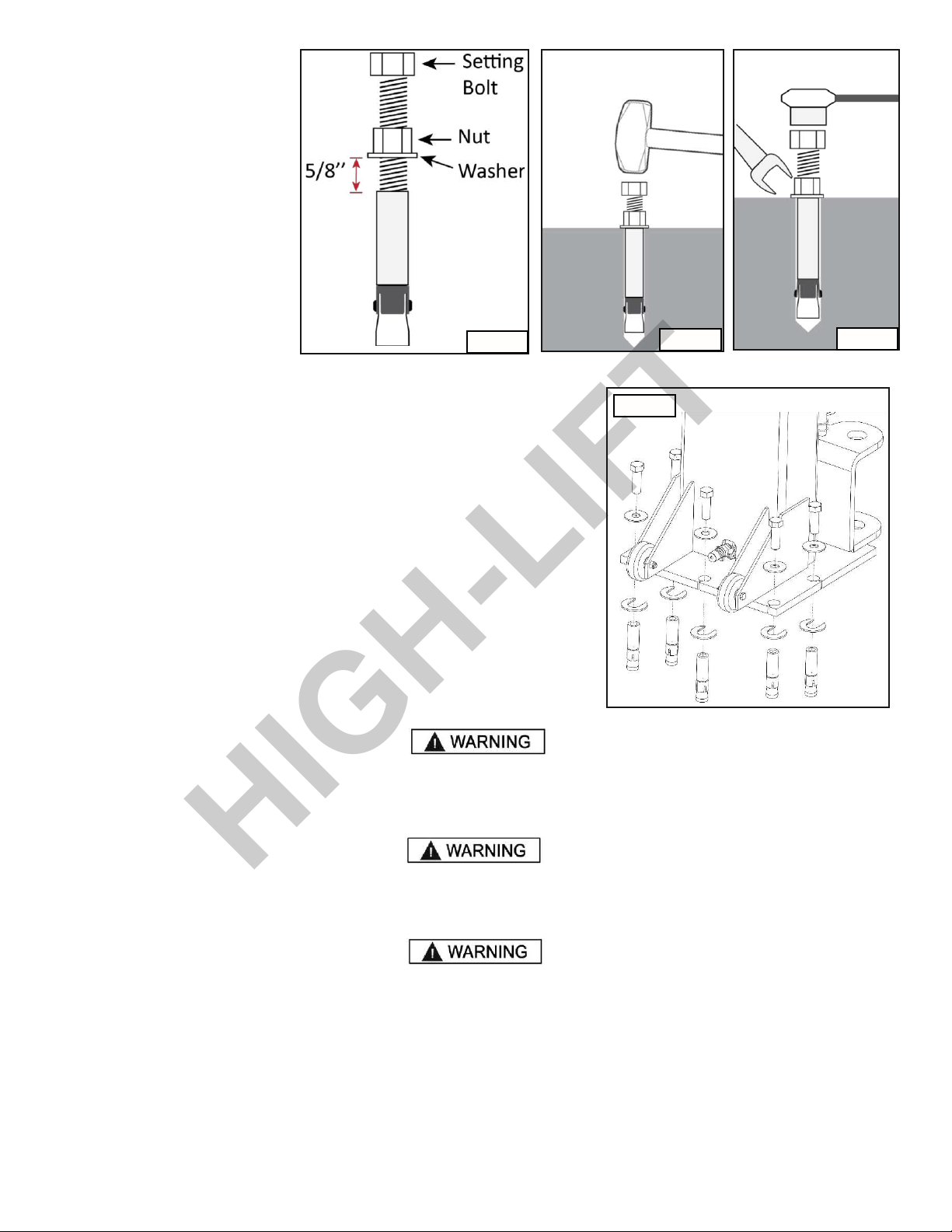

1. Apply white lithium grease or equivalent to the inside of the columns where the slide blocks glide.

2. Test the power unit by pressing the push-button switch. Raise the lift a few inches and check all those connections for

leaks. If the motor gets hot or sounds peculiar, stop and check all electrical connections.

3. Raise the lift to it’s maximum height off the floor until the lift head stops.

4. Lower the lift down below the first safety stop.

POST INSTALLATION CHECK OFF

‡Columns are properly levelled

‡Anchor bolts are tightened

‡Electric power supply confirmed

‡Check for hydraulic leaks

‡Check oil level

‡Lubrication of critical components

‡Check for overhead obstructions

‡Lift arms are level

‡Arm restraints properly adjusted

‡All screws, bolts, and pins are secured

‡Surrounding area is clear

‡Operation, maintenance and safety manuals on site

LIFT OPERATION SAFETY

•NEVER exceed rated capacity of 6,000-lbs.

•Tighten all anchor bolts prior to operation. If anchor

bolts are loose, or any component of the lift is

defective, do not use lift.

•DO NOT remove or disable arm restraints.

•DO NOT block, open or override self-closing lift

controls; they are designed to return to the “Off” or

Neutral position when released.

•ALWAYS inspect all quick connect/disconnect hose

ends before any attempt is made to raise vehicle.

•ALWAYS be sure to have proper overhead

clearance.

•ALWAYS load vehicle on lift carefully. Position the

contact pads according to the vehicle manufacturer’s

recommended lift points. Raise lift until lift pads

contact vehicle. Check pads for secure contact with

the vehicle.

NOTE:

Refer to ALI Quick Reference Guide for all point

recommendations, dangers and safety data.

•ALWAYS remain clear of lift when raising or

lowering vehicles.

•Do NOT use lift if an unlevel lifting condition occurs

that is greater 3.5"(89 mm).

•DO NOT rock the vehicle or remove heavy

components while on the lift that may alter weight

distribution

•ALWAYS ensure Safety Locks are engaged before

any attempt is made to work on or near vehicle.

•NEVER go under raised vehicle if Safety Locks are

not engaged.

VISUALLY CONFIRM THAT ALL SAFETY LOCKS

ARE ENGAGED BEFORE ENTERING WORK

AREA. SUSPENSION COMPONENTS USED ON

THIS LIFT ARE INTENDED TO RAISE AND

LOWER LIFT ONLY AND ARE NOT MEANT TO BE

LOAD HOLDING DEVICES. REMAIN CLEAR OF

ELEVATED LIFT UNLESS VISUAL

CONFIRMATION IS MADE THAT SAFETY LOCKS

HIGH-LIFT