Table of contents

3

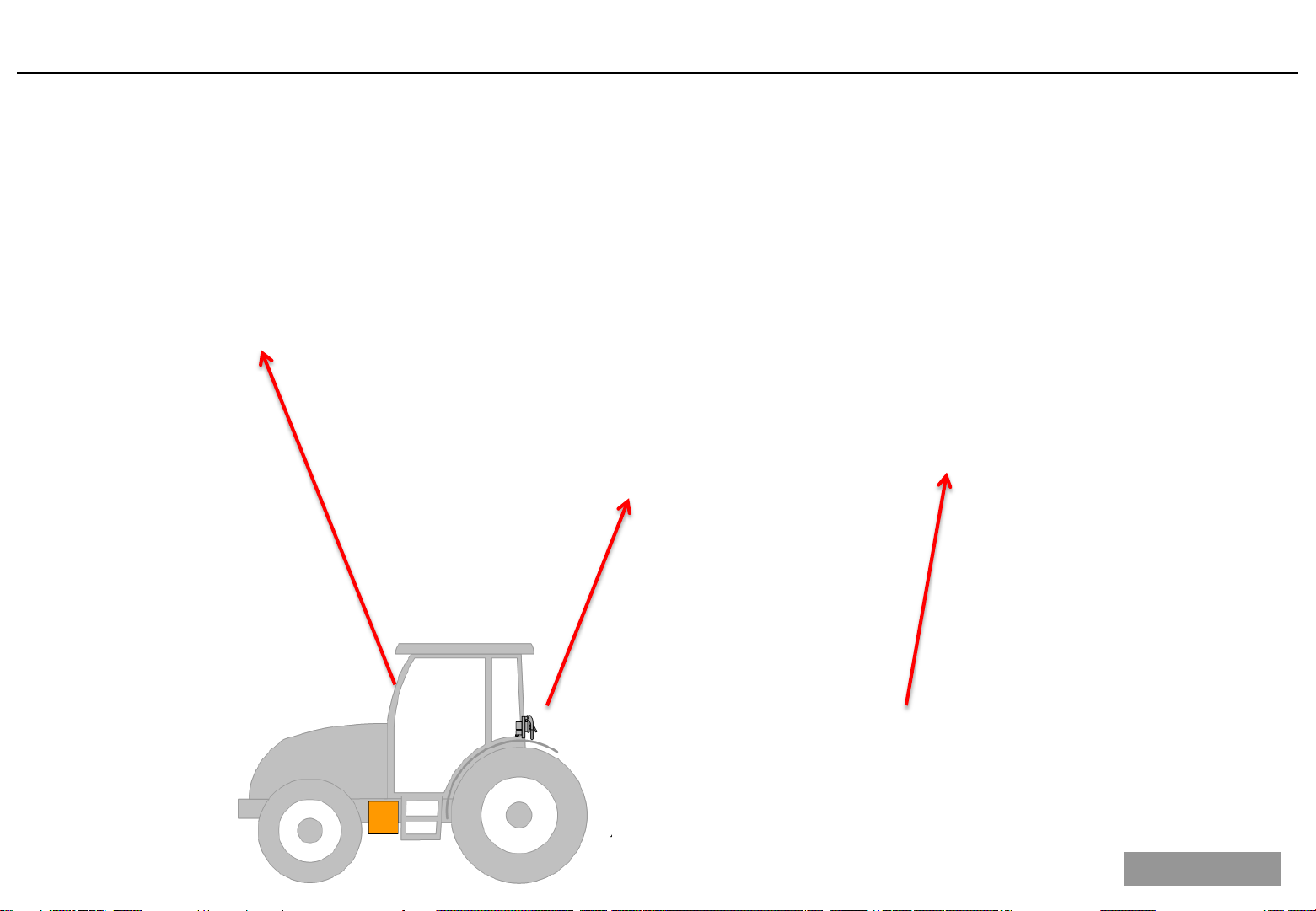

1.1 ISO spreader with a Non

-ISO tractor 4

1.2 ISO spreader with IM Tellus, Tellus GO or PRO

4

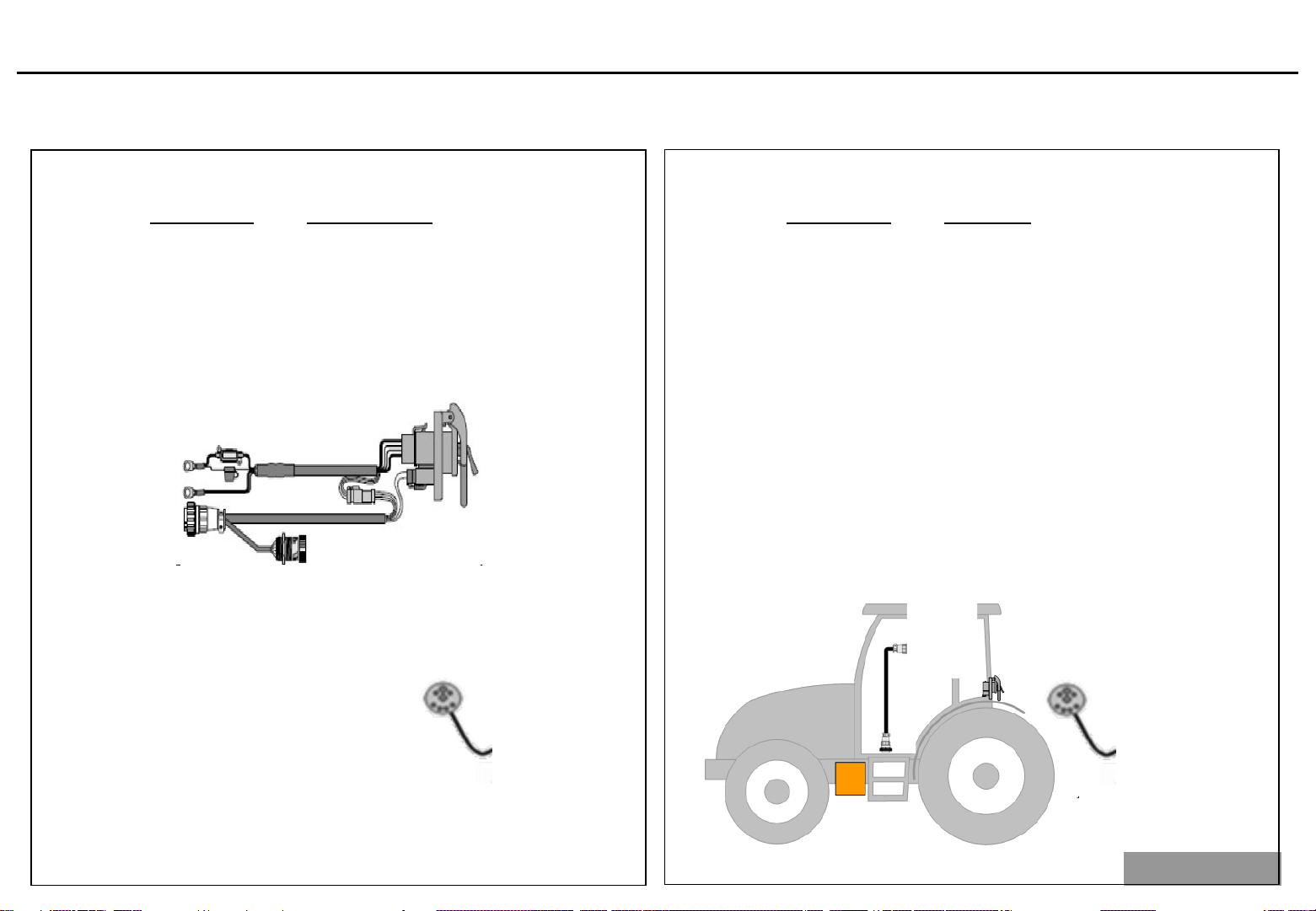

1.3 ISO spreader and ISO tractor

5

6

6

1.4.2 ISO Match Tellus and Tellus PRO

7

1.5 IM power (IsoMatch power)

8

9

1.5.2 IM Tellus connection cable

11

12

-and power cables (Machine side) 13

14

14

17

2.3 Inductie sensor (RPM)

19

21

2.4.1 Check the reference sensor

21

2.4.2 Testing the reference sensor

22

23

24

2.5.2 Test the load cells one by one

25

26

2.6.1 Testing the actuators

27

2.6.2 Measure the actuators

28

2.6.3 Repairing the actuators

29

31

3.1 Machine software EDW ISO II 1.17

32

33

3.3 Service screens: Settings behind PIN Code

38

3.4 Virtual Terminal setting and GEOCONTROL

41

43

46

4.1 Actuators calibration 46

4.2 Hopper calibration: (Pincode 5) 47

4.3 Hopper calibration: (Except CL EW and RO-M EW (Pincode 8) 52

4.4 Hopper calibration: RO-M EW CL EW (Pincode 8) 58

4.5 Speed sensor calibration 62

4.6 Diagnoctic stored calibrated value check 64

5. Border spreading and GEOCONTROL

65

Manual border spreading plate and GEOCONTROL 65

Hydraulic border spreading plate and GEOCONTROL 68

6. Implement setting GEOCONTROL

71

6.1 Calculating B distance

71

6.2 B setting under field conditions

73

76

76

7.2 Trouble should Flowchart weighing system

79

7.3 Trouble should Flowchart actuators

80

8. Electrical hopper cover

81

81

8.2 Connection on PCB and software

82

83

84

85

9.3 PCB connection and software

86

87

88