To stabilize the vehicle once it has been leveled, any unused leveler must be extended into

firm contact with the ground. Accomplish this by using the appropriate individual leg leveling

switch so as not to affect the level of the coach.

CAUTION: Overextending the levelers during stabilizing will cause the vehicle to

become unlevel and result in a loss of stability. If a leveler has been overextended,

press the ‘up’ portion of the respective switch until the vehicle lowers into the level

plane again. Do not attempt to use the other levelers to raise the vehicle to a higher

level plane.

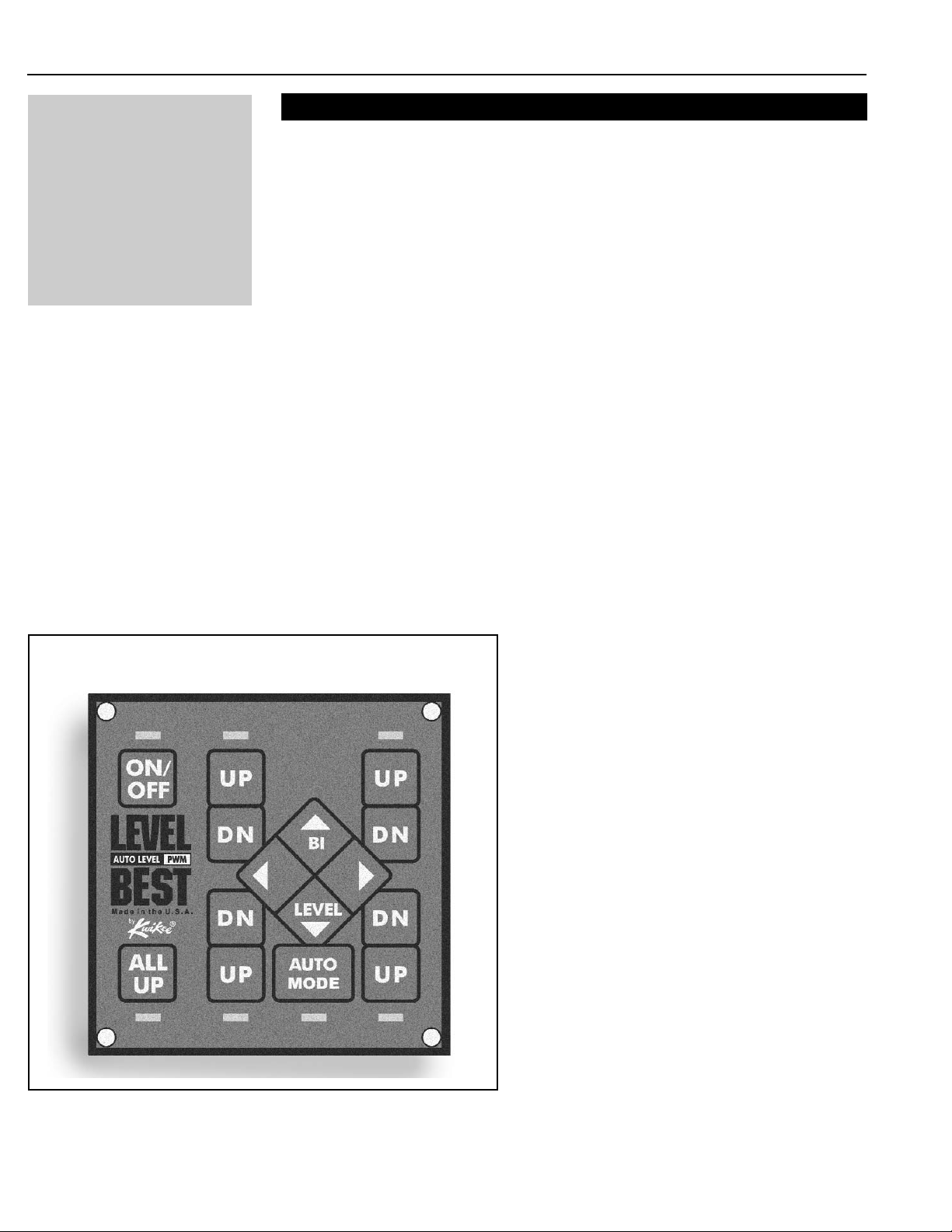

Control Panel Functions

Manual Leveling

The ON/OFF switch, located in the upper left hand corner, controls the supply of power for all

panel functions, activation of this switch is indicated by its green LED.

The ALL UP (leg retract) switch is located in the lower left hand corner of the control panel.

Activation of this switch causes all legs to retract to the travel position. When the retract

sequence is completed the ALL UP LED will turn green to indicate that it is now safe to move

the motor home.

The diamond shaped BI-LEVEL switch, located in the center of the panel, activates the

extension of the leveling jacks in pairs. Use of this switch greatly simplifies the leveling

process and significantly reduces the amount of stress created by the leveling process on the

motor home. Operation of this switch illuminates the yellow LED’s corresponding to the jacks

that are being activated. The LED will illuminate in manual version only.

The four UP/DOWN switches control the leveling jacks independently. Pushing these

switches operates the corresponding jack causing it to retract (UP) or extend (DN). Operation

of this switch lights the yellow LED corresponding with the jack activated. The LED will

illuminate in manual version only.

Level Best Operation Guide Page 3

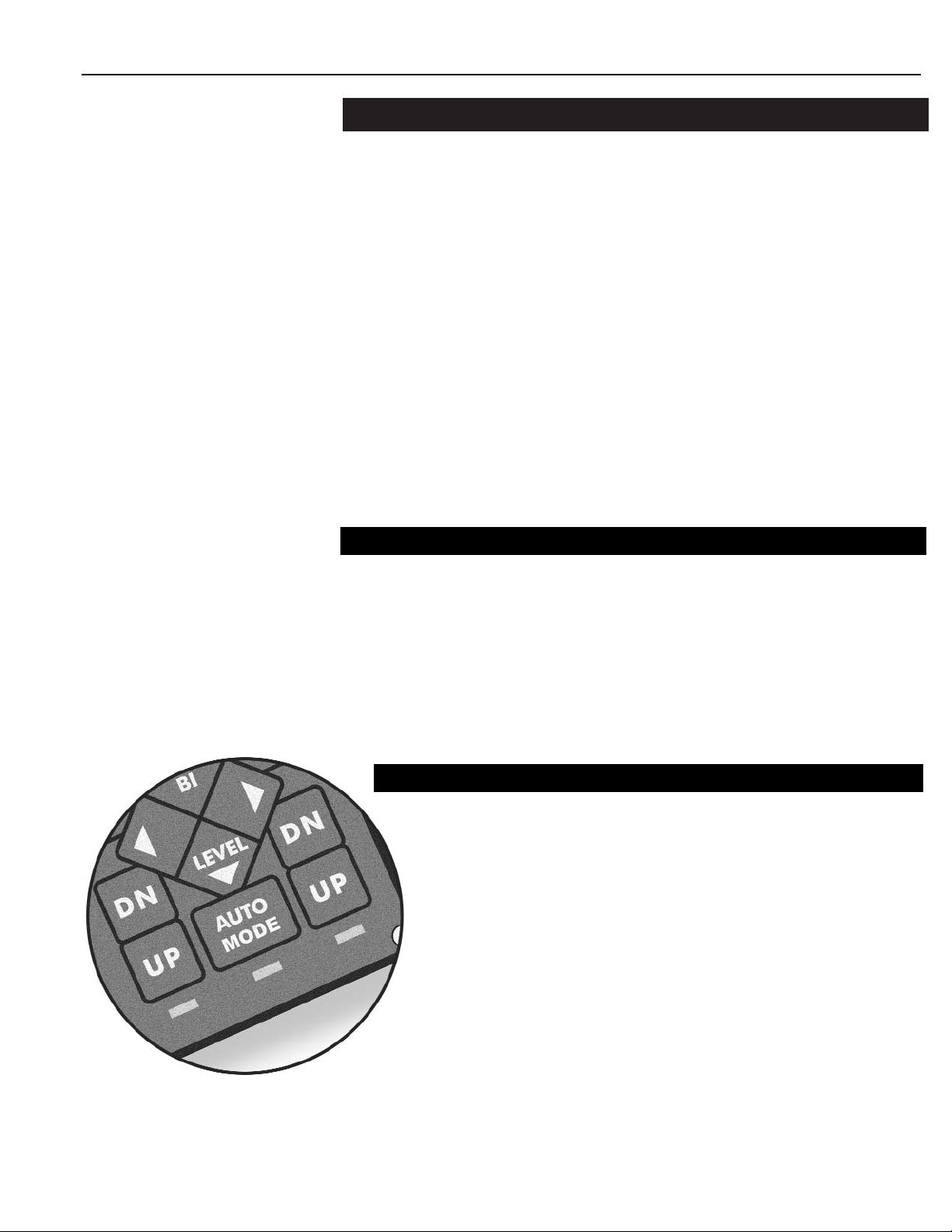

SEMI-AUTOMATIC FUNCTION When an AUTO MODE sensor is connected to

a manual control, the jack indicator lights act as an indicator of the level

condition of the coach. A light that is ‘on’ indicates the high corner of the

coach. Push the BI-LEVEL pair button corresponding to the end of the coach

you would like to raise. When the light comes ‘on’, stop the action of that

button. In this way the jack indicator lights act as a bubble-level, indicating

the level condition of the coach.

FULLY-AUTOMATIC FUNCTION Coaches equipped with AUTO MODE

can be operated the same as manual or semi-automatic versions. The fully-

automatic unit functions the same until the AUTO MODE switch is pressed.

Pushing the AUTO MODE switch causes the system to extend a pair of jack legs

to the ground. Next the other pair of legs is extended to the ground and the system

begins the auto level sequence. During the auto level sequence the system will run

one to three of the jacks depending on the level condition of the coach. On completion,

the system will check the level condition of the coach and either re-run the sequence

or display a green LED light under the AUTO MODE button to indicate that the

sequence is complete. Typical coach level capability is 0.3 degrees from side to

side and front to rear.

Automatic Leveling