1. Safety instructions

Before using this product, please carefully read all safety and operation instructions in this manual. Operation in

violation of the manual may cause danger or damage to the equipment.

2.2 Attention

1.Use the product as instructed in the manual. Only use the accessories recommended or sold by the manufacturer.

2. Make sure the supply voltage meets the voltage specified on the charger.

3. Before using the product, make sure that the battery and shell have been installed in place, and the battery power is sufficient.

4. If the power cord is damaged, it must be replaced by the manufacturer, its maintenance department or aprofessional to avoid

danger.

5. Please turn off the power switch or pull the plug from the power socket before cleaning and maintaining the product.

6. In case of power failure, waterproof covers must be installed on connectors and sockets, and ensure that the waterproof covers are

clean and free of foreign matter.

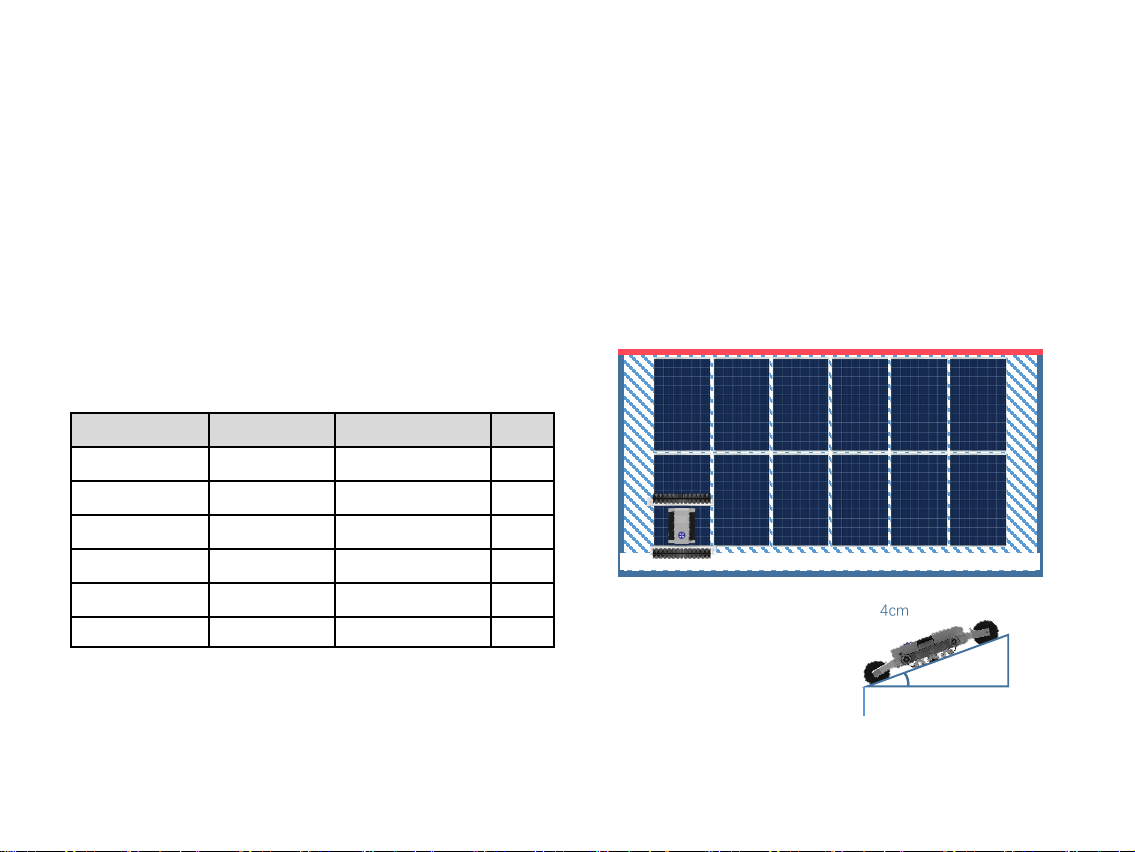

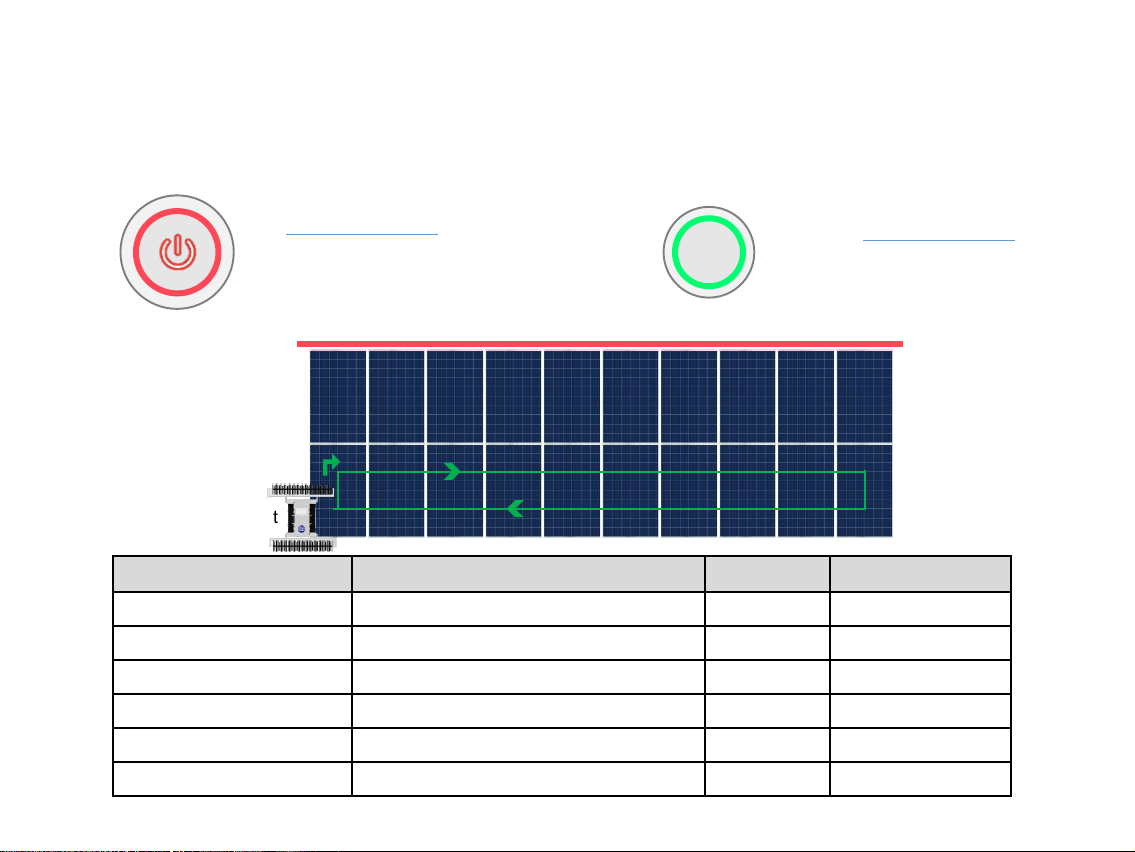

7. Before placing the Kwun in the initial position of the photovoltaic array, ensure that the surface of the initial position is clean in

advance to prevent the product from slipping or falling due to serious pollution of the track.

8. After cleaning job, clean the anti-fall sensor with a wet towel and then wipe it with a dry towel to prevent excessive accumulation of

dust and affect the perception.

9. Before discarding the product, turn off the power switch and remove the battery. Remove and discard the battery in accordance

with local laws and regulations.

10. If the product is not used for a long time, please turn off the power switch and power off the product.

11. Wear ESD gloves when touching the Kwun.

12. Do not use the product with damaged batteries or chargers.

13. It is only used in the PV array with an inclination of less than or equal to inclination 20°(dry brush) or 15 °(wash) , the PV array

edge range of 50cm is free of obstacles and the lowest point is suspended above 10cm.

14. Do not use the product when it cannot work normally due to drop or damage. To avoid injury, the product should be repaired by

the manufacturer or its after-sale service.

15. Please use the product according to the instructions in the manual. Kwunphi company is not responsible for any loss or injury

caused by improper use.

2