Downloaded from www.coronatechnical.com manuals search

engine

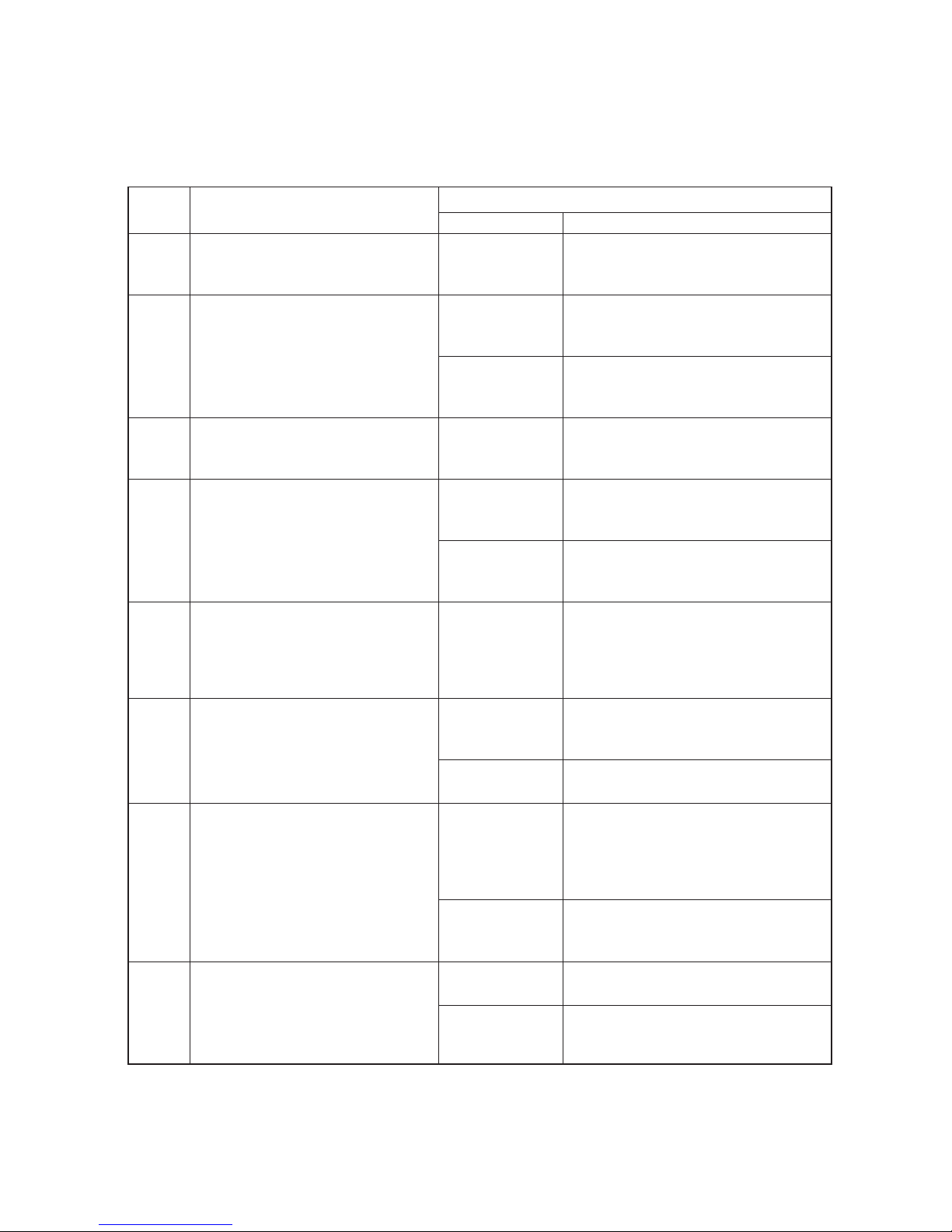

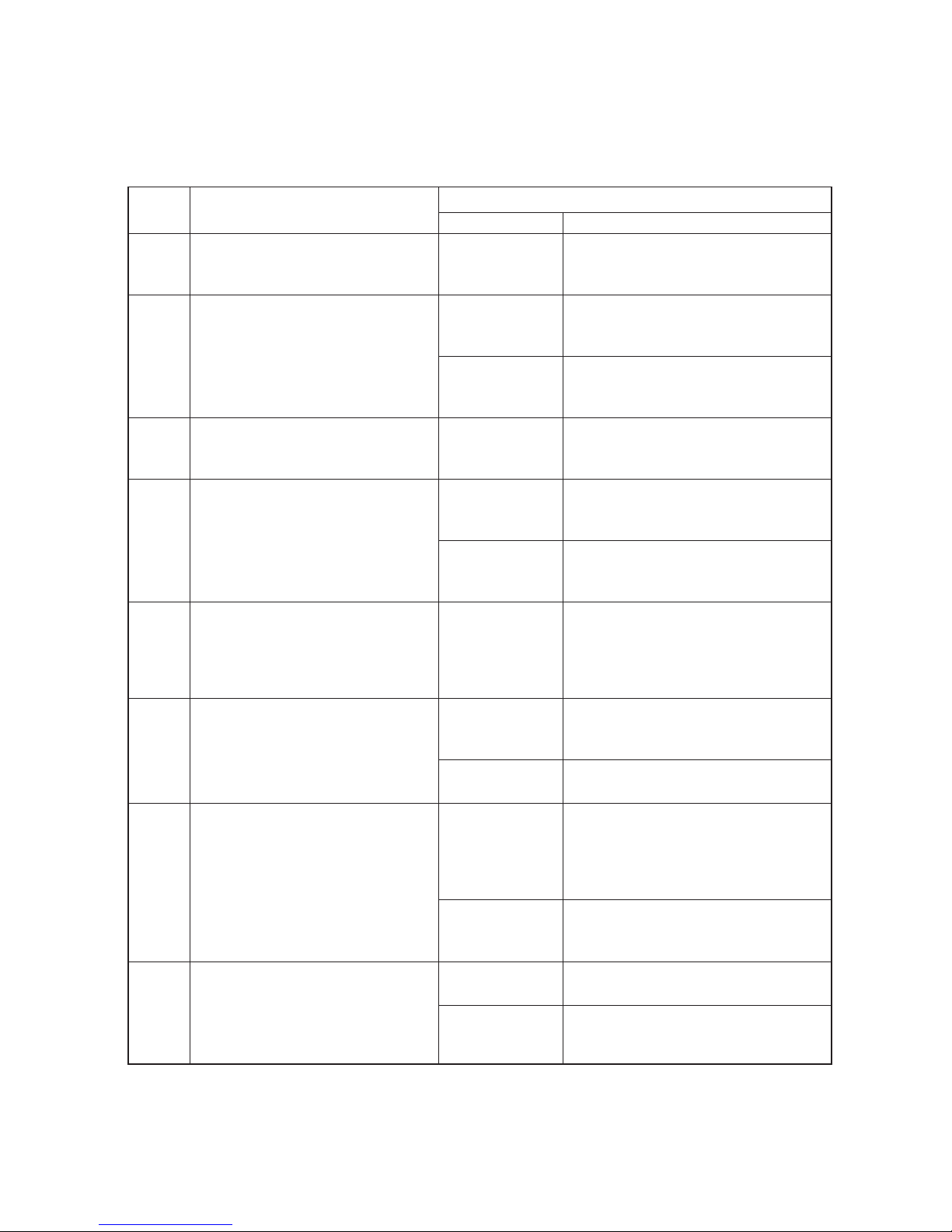

Kyocera KM-1620/ KM-2020 Error Code List

Self-diagnosis

(1)

Self diagnostic codes

Check procedures/corrective measures

Backup memory read/write problem

(main PCB)

•

Read and write data does not match.

Defective backup

RAM or main

PCB.

Replace the main PCB and check for cor-

rect operation.

Backup memory data problem (main

PCB)

•

Data in the specified area of the

backup memory does not match the

specified values.

Problem with the

backup memory

data.

Turn safety switch off and back on and run

maintenance item U020 to set the contents

of the backup memory data again.

If the C011 is displayed after re-setting the

backup memory contents, replace the

backup RAM or main PCB.

Backup memory read/write problem

(engine PCB)

•

Read and write data does not match.

Defective backup

RAM or engine

PCB.

Replace the engine PCB and check for

correct operation.

Backup memory data problem (en-

gine PCB)

•

Data in the specified area of the

backup memory does not match the

specified values.

Problem with the

backup memory

data.

Turn safety switch off and back on and run

maintenance item U020 to set the contents

of the backup memory data again.

If the C016 is displayed after re-setting the

backup memory contents, replace the

backup RAM or engine PCB.

Accounting count problem

•

When the power is turned on, the to-

tal count and the scan count are ab-

normal both on the main PCB and the

engine PCB.

Defective main

PCB or engine

PCB.

Replace the main PCB or engine PCB and

check for correct operation.

Machine number mismatch

•

When the power is turned on, thema-

chine number does not match be-

tween the main PCB and the engine

PCB.

Correct EEPROM

is not installed.

Install the correct EEPROM. If it does not

solve the problem, contact the Service Ad-

ministrative Division.

Contact the Service Administrative Divi-

sion.

Communication problem between

the main PCB and engine board PCB

•

When the power is turned on, thema-

chine does not detect the low level of

SBSY and the high level of SDIR for

three seconds.

Poor contact in

the connector ter-

minals.

Check the connection of connectors YC6

on the main PCB and YC1 on the engine

PCB, and the continuity across the connec-

tor terminals. Repair or replace if neces-

sary.

Defective main

PCB or engine

PCB.

Replace the main PCB or engine PCB and

check for correct operation.

Optional DP communication problem

•

Communication fails five times suc-

cessively.

DP installed incor-

rectly.

Check the installation state of the DP and

adjust it if it is not properly installed.

Defective main

PCB or DP driver

PCB.

Replace the main PCB or DP driver PCB

and check for correct operation.

“A” is displayed on the operation panel.