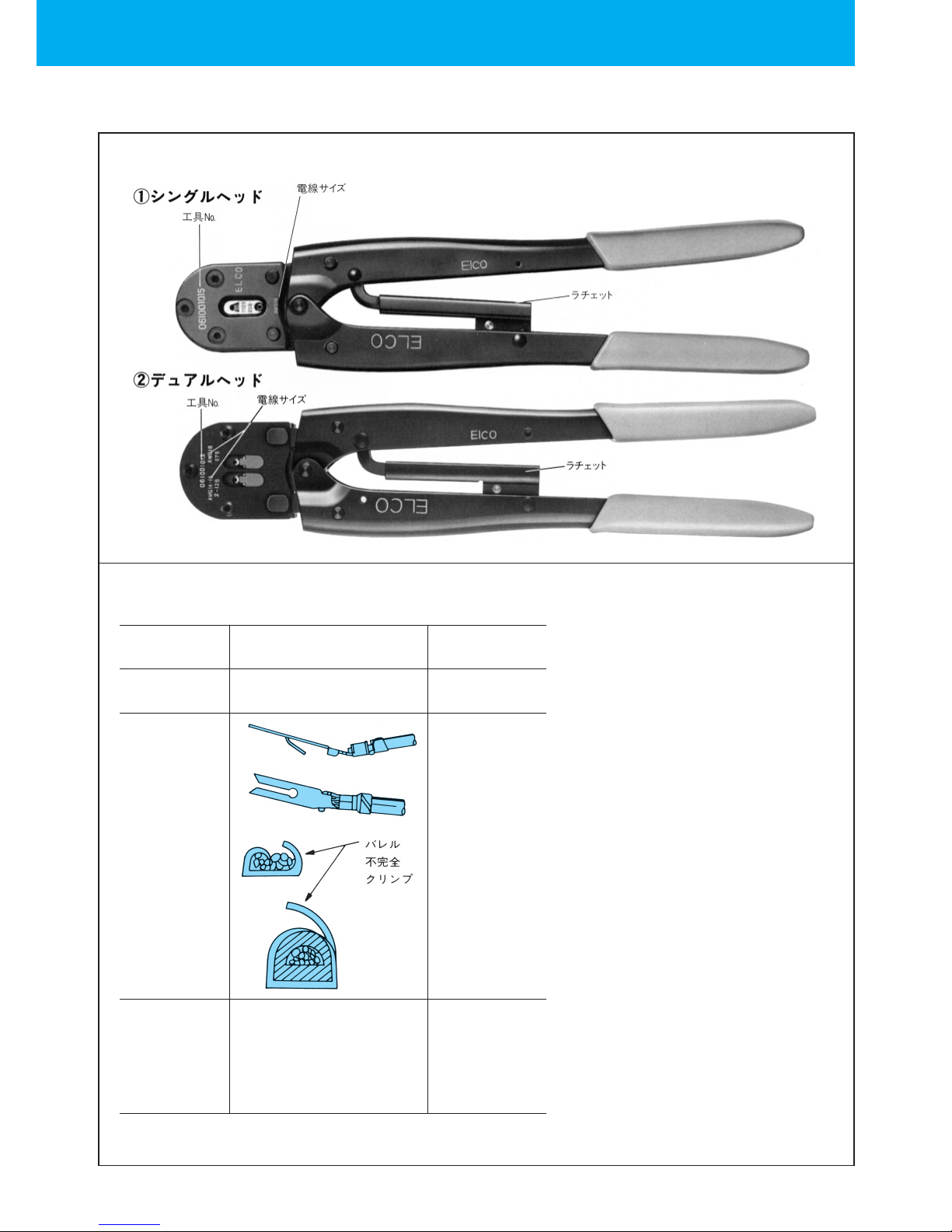

Type B

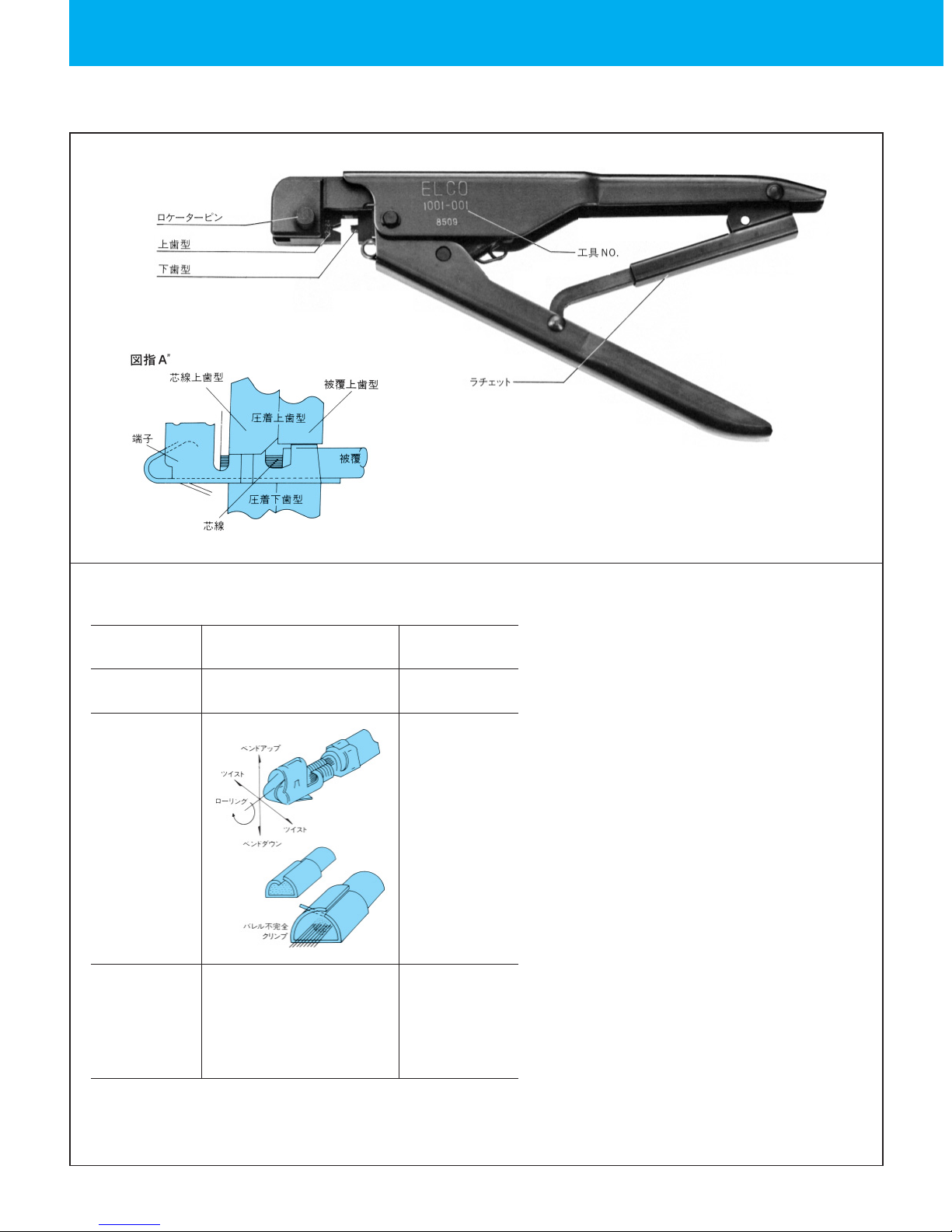

Structure of the Tool and Part Names

With this tool, a strip of contacts can be crimped easily with the applicable wire

by using a set of crimper and anvil. (No need to replace the crimper and anvil.)

Example of Failure

Selecting the appropriate crimper

1.Requisite blades are attached on top and bottom of the crimper.

2.The number of applicable size of the wire is engraved on the crimper.

3.Select the crimper to the size of the wire.

4.When replacing the crimper, pull out the locator pin.

(The locator pin can be pulled out with fingers easily.) で簡単に抜く事が出来ます。

5.Install the appropriate crimper and fix it with the locator pin.

Procedures

1.Make sure that the tool number and the wire size are met.

2.Cut the strip of contacts in 20cm.

3.Insert the cut strip of contacts into the contact feed bar.

4.Feed the contacts to the proper position.

5.Strip the wire and insert the contact appropriately.

6.Close the grips until the latchet is released.

7.Open the grips to pick up the contact.

8.Feed the contact with stripped wire to the proper position.

9.Make sure that the shape of the crimped work is appropriate.

Failure Item Failure Description

Pull strength is out of specification.

1)Malformation of

the crimped area

(

Wire barrel)

1.Bend

2.Twist

3.Deformation

工具クリンプ位置が一定でない場合

珎クリンプハイトの

バラツキ

Cause

The wire size is out of

用又は工具の摩耗

歯型に対し端子が中心

にセットされていない

ラチェット の摩耗及び

変形により、ハンドルを

完全に締付けない位置

(中間位置)、で も復帰

する状態となっている

場合に起きる

Locator pin

Tool identification number

Ratchet

Locator pin

Crimper

Crimper fixing screw

Contact feed bar

Anvil

Crimper

Head

Movable cutter

Fixing screw

Anvil Grip

Shaft pin

Wire crimping part

Wires

Cladding insulator crimping part

2)Deformation of

the terminal

3.Deformation

of the barrel

Cause

The wire size is out of

the specification, or

abrasion of the tool

The terminal is not

set in position against

the crimper and anvil.

3)Variation in

crimp height The crimping height

of the tool is not fixed.

Occurred when grips

are incompletely

tightened (tightened

half way) but in the

position where they can

be open due to the

abrasion or deformation

of the ratchet.

Bent up

twist

twist

ト

Bent down

Rolling

Incomplete crimping

of the barrel