1

YourKZRVrecreationalvehicleisdesignedto beasmaintenance

free aspossible. However,all moveablevehiclesrequiresomecare

to reducethe possibilityofunwanted breakdownsduringtravel.

MaintenanceofyourRVmaynot seemnecessaryat the timeof pur-

chase, yetitisveryimportant tokeep yourcoachinit’sbestcondi-

tionforyourenjoyment. Normalmaintenanceisrequired tomaintain

warrantycoverage, reducewear, and prolong the life of yourcoach.

1. FRAME

The steelframeon yourKZrecreationalvehicleiscleanedwith a

highpressurephosphate spraywashthat removesoils,dirt, and

residue.Aftercleaning the frame isplacedin an ovenat 200°F,high

quality,waterborne paint is then applied. Afinalcuring process is

then applied to producea qualitypaintapplication.

No matterwhat qualityortypeofpaint process isused, wemust

rememberthat duringtravelthe frameisexposed tostones,sand,

road debris,andanyotherobjectsfound onthe road.Theseitems

willcausescratching and chippingofthe paint invitingrustto begin

frommoisture. Yourframeneedsto beinspected and examined

everyyeartotouchuporrepaint asnormalmaintenance. Wesug-

gestthisbe performed eachfall beforestorage toguardagainstwin-

termoisture.

The paintto useisagloss black,ozone safeexteriorpaint with no

fluorocarbon,ina spraycan.

You maywishtopurchaseacommercialrustproofundercoating

treatment, suchas,Ziebart®,etc.However,evensuchhigher

priced treatmentsare subject to roaddebrisand damage.

2. COUPLER (Travel Trailers)

Forthe ball on yourhitchusealight amount ofchassisgrease.

Lubricatethe coupler’spivotpointswithsiliconespray.Avoid

grease oroilastheywilldrawdirt, potentiallydamaging thecoupler.

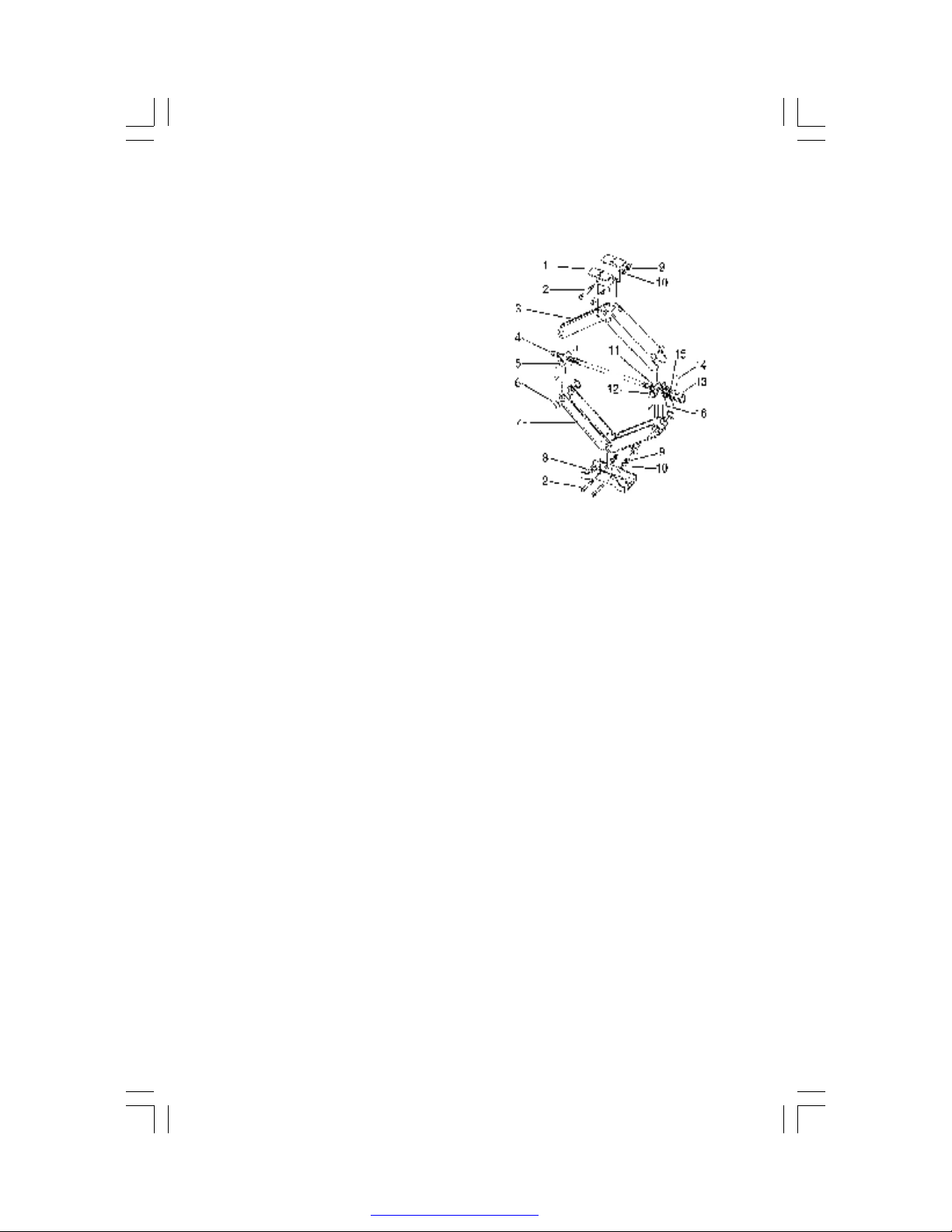

3.JACKS— FORRAISING/LOWERING/SUPPORTS

Numeroustypesofjacksareused inconstructingarecreational

vehicle,suchasstabilizer,tongue ontraveltrailer,landinggear

and formallyon truckcampers.

Eachofthesehave12voltD.C. powermotors available, saving

manuallaborasan option.

Shouldanyframepartsof thesejacksbecomedirtyand rusty,first

clean all partsand then paint asneeded, toimproveappearanceDO

NOTpaint anymoving parts.

ChapterI — Undercarriage

PDFcreated withpdfFactorytrialversion www.pdffactory.com