Start-UUpIInstructions

Determine the pilot control valve type supplied on the heater.

For heater with gas control valves with an internal low

pressure regulator and gas shut off, refer to Section A.

For heaters with gas control valves without an internal low

pressure regulator and gas shut-off, refer to Section B.

Follow all procedures within the appropriate section on initial

start-up after heater installation by qualified gas heater

service person. For normal start-up simply turn the

thermostat above room temperature. The heater will start.

ATTENTION

■On new installations it may take about a minute for

the gas to purge out any air in the pilot line before the

pilot stays lit.

SECTION AAControl VValves wwith IInternal

Low PPressure RRegulator aand GGas

Shut-OOff

1. Open all manual fuel supply valves and check for gas

leaks using approved leak detectors.

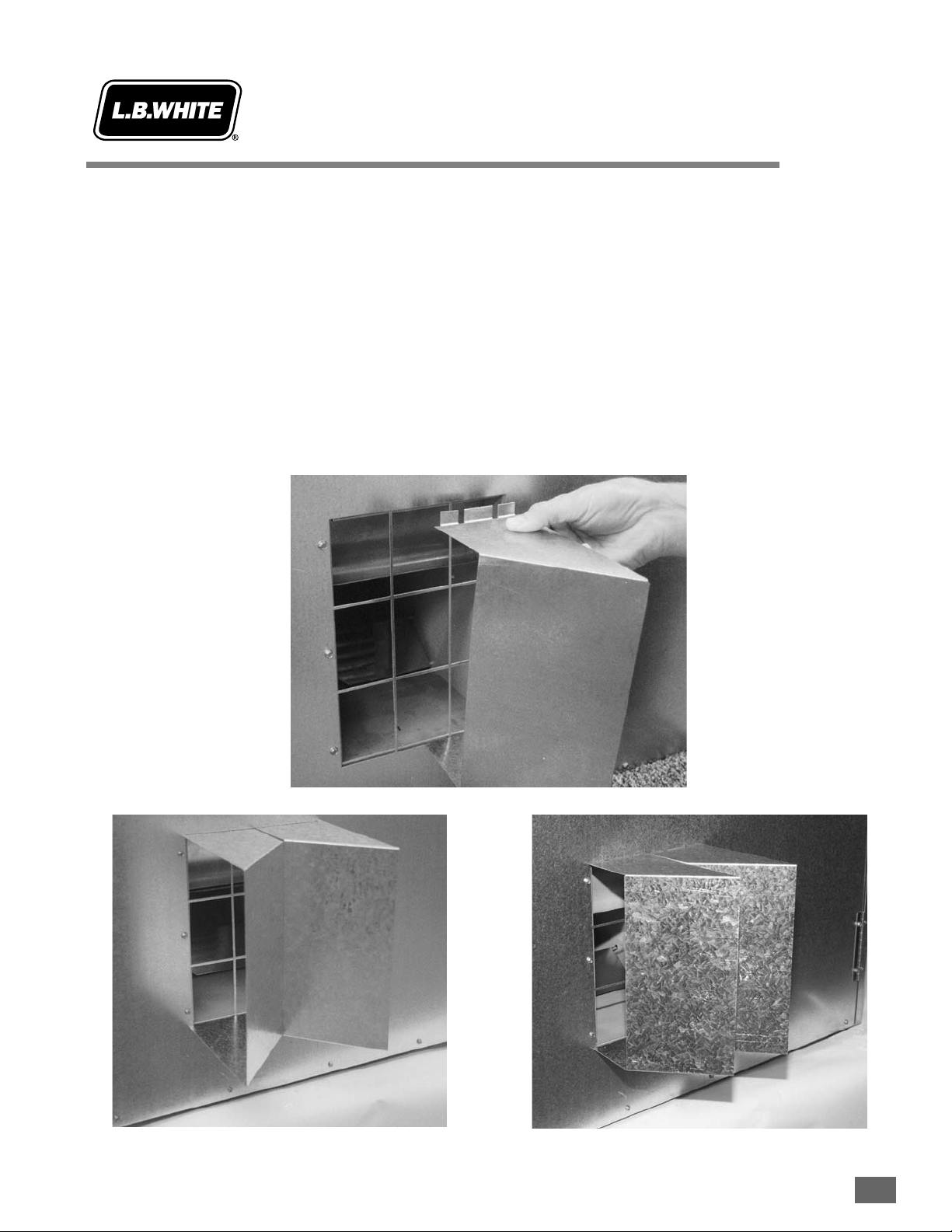

2. Remove the metal cover from the control enclosure (if

applicable).

3. Position the indicator arrow on the control valve’s

shut-off knob to “pilot”.

4. Fully depress the pilot button while applying flame to

the pilot burner.

5. Keep the button depressed for about 30 seconds to

allow the thermocouple to warm up so the pilot stays

lit after the pilot button is released.

6. Position the knob to “on”.

7. Reinstall the metal cover (if applicable).

8. Connect the heater’s power cord to an approved

electrical supply.

9. Set the thermostat above room temperature. The

heater will light.

10. Reset the thermostat to desired room temperature.

SECTION BBControl VValves wwithout IInternal

Low PPressure RRegulator aand

Gas SShut-OOff ((Part 5500-002309)

1. Open all manual fuel supply valves to the heater and

check for gas leaks using approved leak detectors.

2. Fully depress the pilot button while applying flame to

the pilot burner.

3. Keep the button depressed for about 30 seconds to

allow the thermocouple to warm so the pilot stays lit

after the pilot button is released.

ATTENTION

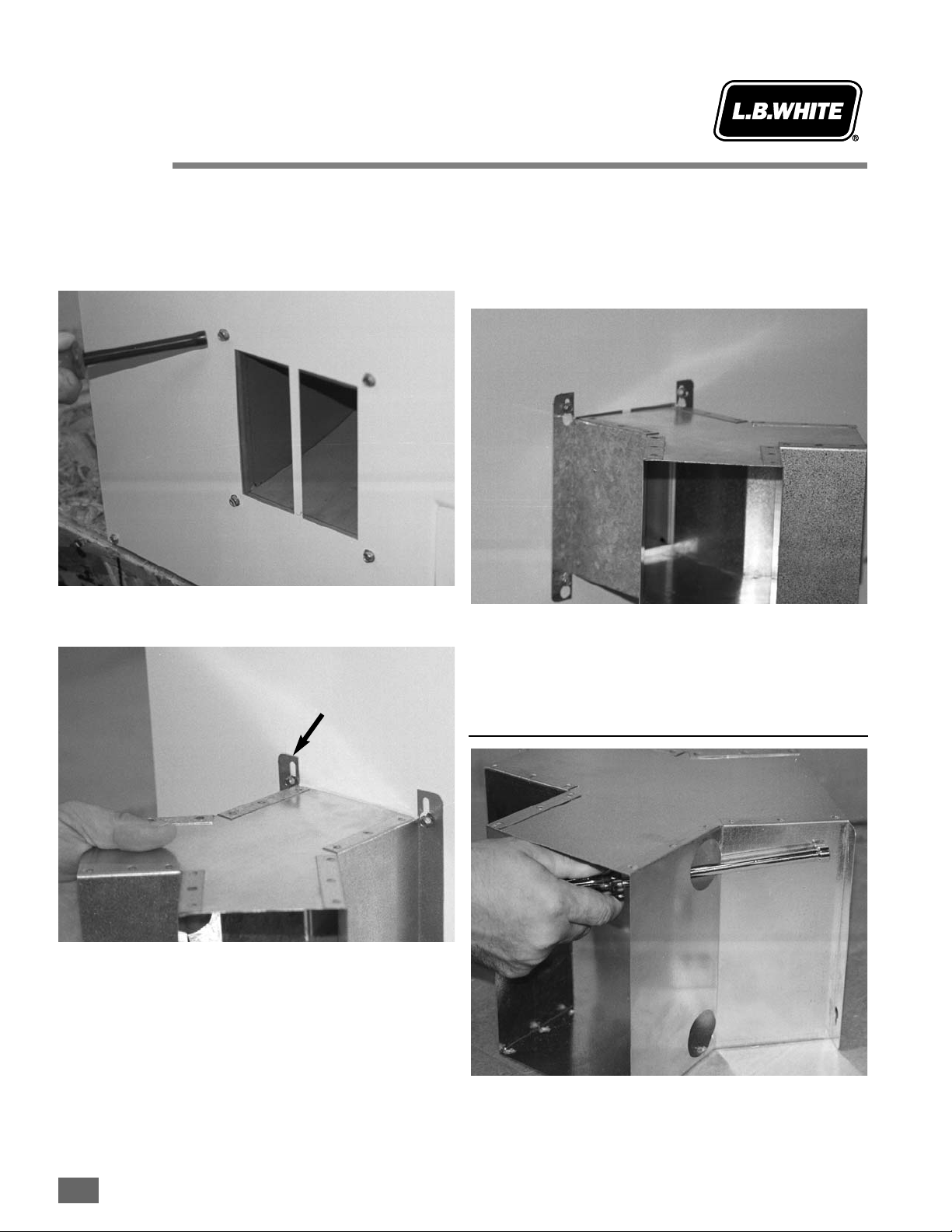

■The red cap protecting the pilot control may become

stiff in colder temperatures.

■Remove the cap and fully depress the pilot button to

light the pilot. Reinstall the cap.

4. Connect the heater’s power cord to an approved

electrical supply.

5. Set the thermostat above room temperature. The

heater will light.

6. Reset the thermostat to desired room temperature.

August 1999 3.1-11

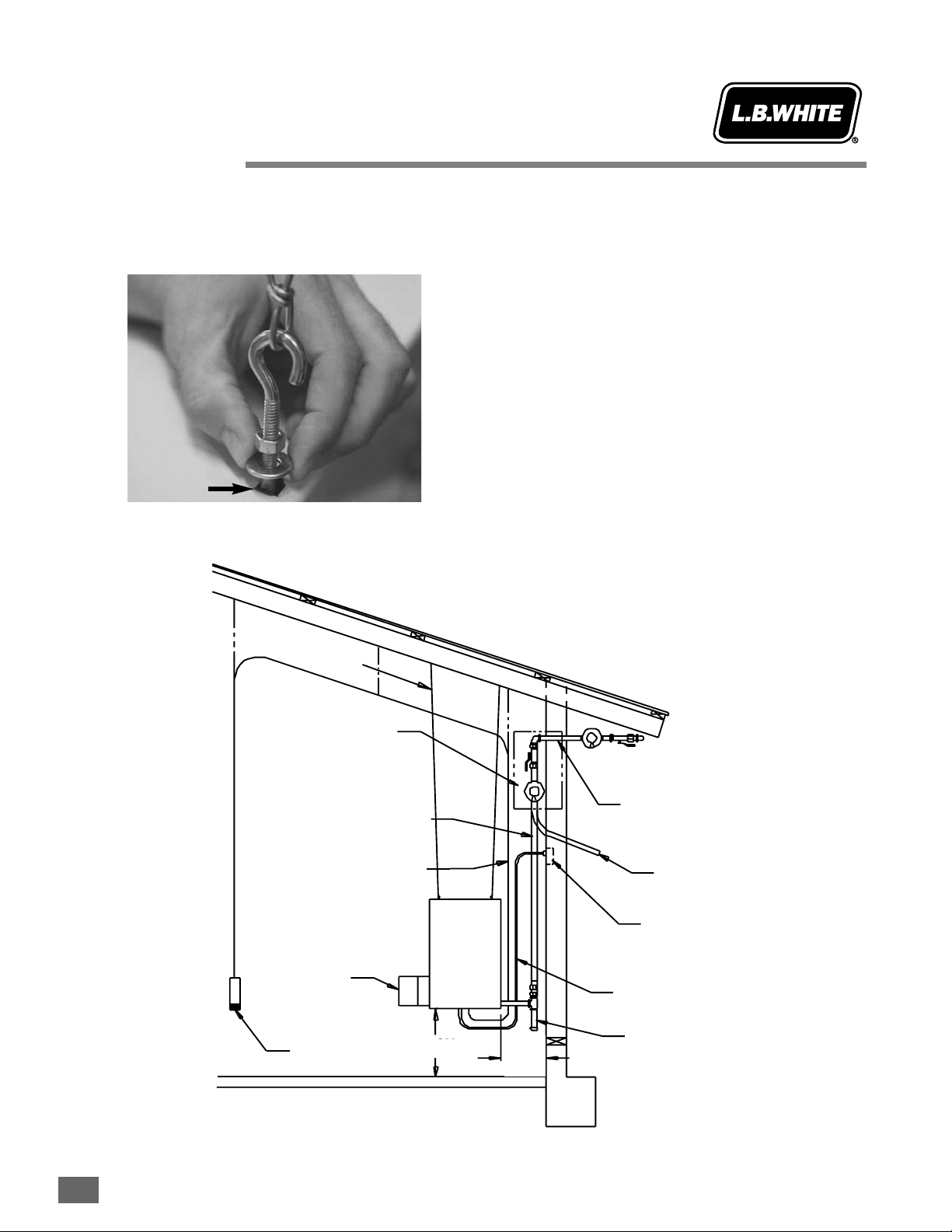

Pilot

Button

Knob

Pilot

Button

Start-Up and Shut-Down Instructions

Operation

Instructions