- 7 -

• To decrease the volume, turn the

volume seng knob clockwise.

• To increase the volume, turn the

volume seng knob counterclock-

wise.

• Do make sure that the d e s ired

delivery volume is set in-line with

pointer.

• Turn the volume lock to “lock” the

vol um e se ng , p reve nn g any

accidental change in the volume

during pipeng.

For this pipee the delivery volume of

liquid is set using the digital display. A

pointer is u sed to set exact or

intermediate volumes using the scale

on the last wheel of digital display

(refer point # 4.6)

The Locking mechanism ensures that the volume adjustment

knob remains at the setpoint while aspirang or dispensing sample

liquids. Any effort to rotate the volume adjustment knob with the

locking mechanism engaged will damage the locking mechanism

and void the warranty.

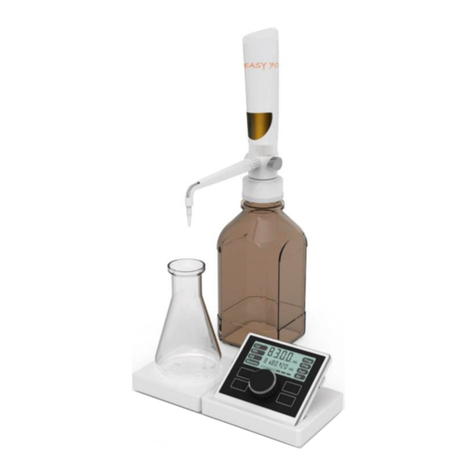

5.2 SETTING THE VOLUME

• To set the volume turn the volume lock lever to the “unlock”

posion so that the volume can be adjusted to the desired

setpoint within the permied volume range. Refer following

images

• Aer pipeng acids or other corrosive liquids that emit vapors,

remove the p-cone and rinse the piston, O-ring and seal with

dislled water.

• Do not pipee liquids having temperatures above 70°C. (Not

recommendable)

• Make sure that liquids never enter the p-cone. To prevent

this:

Avoid laying the pipee horizontally when p is filled with

sample. As liquid may enter in and contaminate the sample

during next pipeng cycle.

When there is liquid in the p, press and release the volume

adjustment knob slowly and smoothly.

Never turn the pipee upside down.

• Always store the pipee without p on a shelf mounng

stand supplied with or a pipee carousel stand.

• Highly recommended to calibrate the pipee once in every 3-

6 months (depending on the sensivity of usage) for beer

performance. The calibraon must be carried by gravimetric

method in accordance of DIN ISO 8655-6.

Volume

adjustment

Knob

100

1000

100

1000

µl

100

1000

µl