Berthold NightOWL II LB 983 User manual

Service Manual

NightOWL II

LB 983

ID-No. 40508SA2

Rev. 03 17.09.2010

Contents NightOWL LB 983

i

Contents

1. INSTALLATION 1-1

1.1 Camera installation (Ethernet version) 1-1

1.2 Camera installation (USB version) 1-2

1.3 Connecting the instruments 1-2

1.4 Connecting the PC (Ethernet) 1-3

1.5 Connecting the PC (USB) 1-4

1.6 USB Mode programming 1-4

1.7 Software installation (indiGO) 1-6

1.8 Shipping instructions 1-8

2. CALIBRATION 2-10

2.1 Focus calibration 2-10

2.2 Quantum Efficiency 2-12

2.3 Flat field calibration 2-12

2.4 Energy Calibration 2-13

2.5 Calibration data 2-15

2.6 Other Data Files 2-15

3. CCD CAMERA 3-1

3.1 Dismantling the Camera 3-1

4. SAMPLE CHAMBER 4-2

4.1 Taking Off/Attaching the Cover 4-2

4.2 System Electronics 4-3

4.3 Service Software 4-5

4.3.1 Start software 4-5

4.3.2 Check drives 4-6

4.3.3 Check halogen lamp 4-8

4.3.4 CAN modules 4-8

4.3.5 CAN node installation 4-8

4.4 Firmware update 4-10

4.5 Fluorescence Illumination 4-12

4.5.1 General 4-12

4.5.2 Design 4-12

4.5.3 Lamp replacement 4-13

4.5.4 Module replacement 4-13

Contents NightOWL LB 983

ii

5. CLEANING AND MAINTENANCE WORK 5-1

5.1 Cleaning the camera compartment 5-1

5.2 Cleaning the camera 5-1

5.3 Replacing the air filter 5-1

5.4 Replacing the fuse 5-1

5.5 Setting the door sensor 5-2

5.6 Trouble shooting 5-2

5.6.1 Camera lift sits on sample carrier 5-2

5.6.2 Camera lift sits on bottom of acquisition chamber 5-3

5.6.3 Camera lift hits ceiling of acquisition chamber 5-3

6. APPENDIX 6-1

6.1 Technical data 6-1

6.2 Spare parts list 6-3

6.3 Wiring diagrams 6-4

NightOWL LB 983 Installation

1-1

1. Installation

Each instrument comes with the following accessories:

Manual (either in German or English, depending on your order)

indiGO software with ”Calibration Data” on a memory stick

Power cord (depending on the country)

USB or network cable (depending on the camera version)

The camera is packed separately. The camera case contains:

Camera

Mounting screws

Ethernet cable (RJ-45) or USB cable

1.1 Camera installation (Ethernet version)

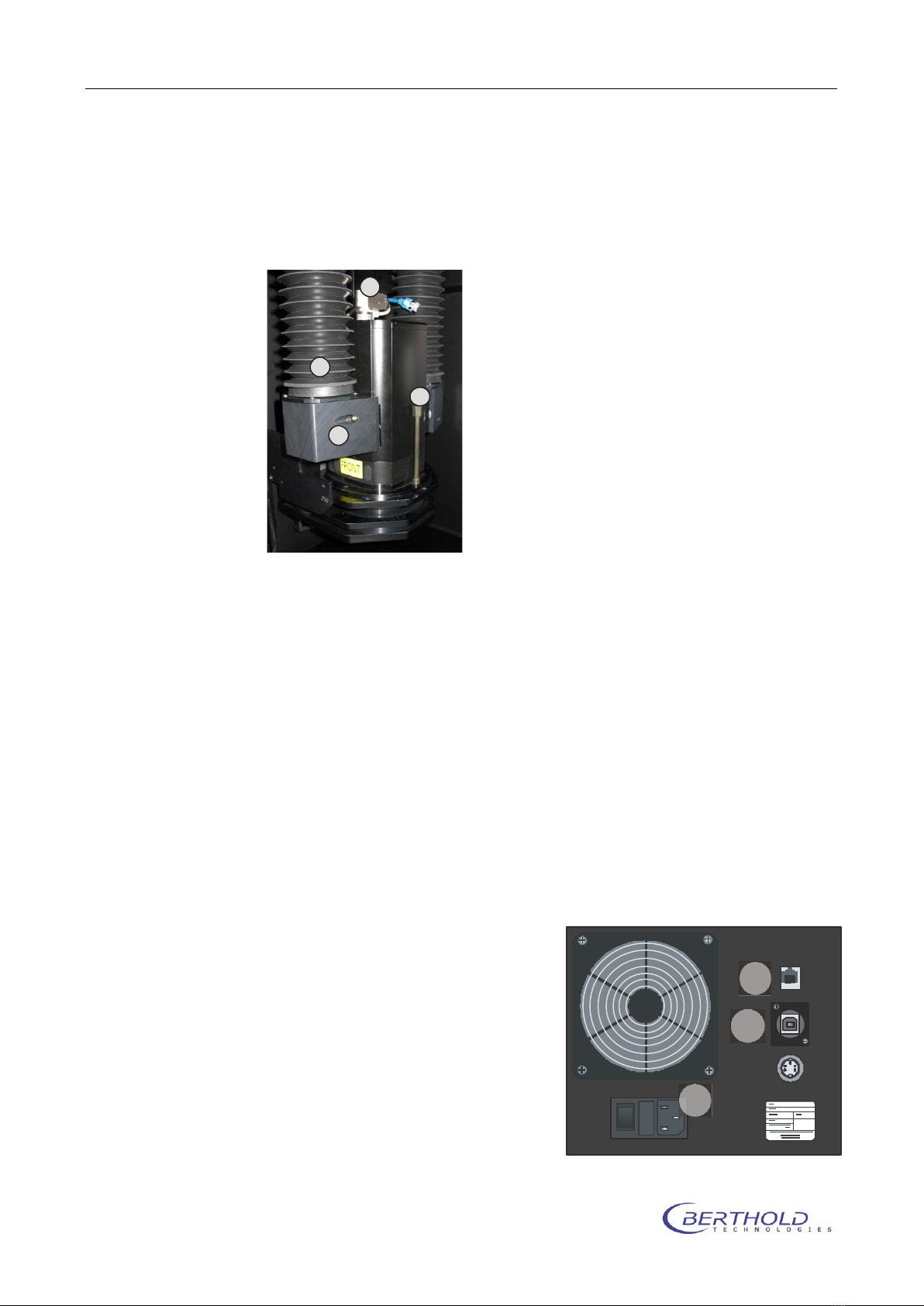

Place the camera on the camera holder showing the NightOWL

logo on the camera to the front. Fix the camera using the two fas-

tening screws as shown on the picture.

The two bellows (1) are fixed to the camera adapter (2) with spe-

cial magnets.

The Ethernet cable (RJ-45 connector) and the power supply con-

nector are plugged in at the upper plate of the camera.

1.2

Installation NightOWL LB 983

1-2

Camera installation (USB version)

The NC 100u uses the USB bus to transfer images and camera

control. To install the camera just place the camera on the cam-

era plate facing the “FRONT” label to the front.

Fix the camera with the 2 fastening screws (3). The power supply

(4) is connected through a 7 pin Tuchel connector. This connector

is on the camera face plate and connects to the power supply

connector on the camera plate.

The air adapter (1) is fixed to the camera by a megnet, as well as

the air bellow (2).

When uninstalling the camera remove the power adapter to avoid

damage during transport.

The USB plug is also located at the face plate of the camera. The

cables should be arranged as shown in the image above.

1.3 Connecting the instruments

Connect the instruments as follows:

PC -> NightOWL (rear panel)

Power -> Mains socket (1)

LAN port -> LAN socket (2)

(RJ-45 cable) and / or

USB port -> USB socket (3)

Check to make sure that the

system voltage indicated on the

instruments matches the line

voltage.

Connect all three instruments

(PC, monitor, NightOWL) via one

connector strip to the mains

1

2

3

4

CE

I

01

2

3

NightOWL LB 983 Installation

1-3

supply and turn the instruments on.

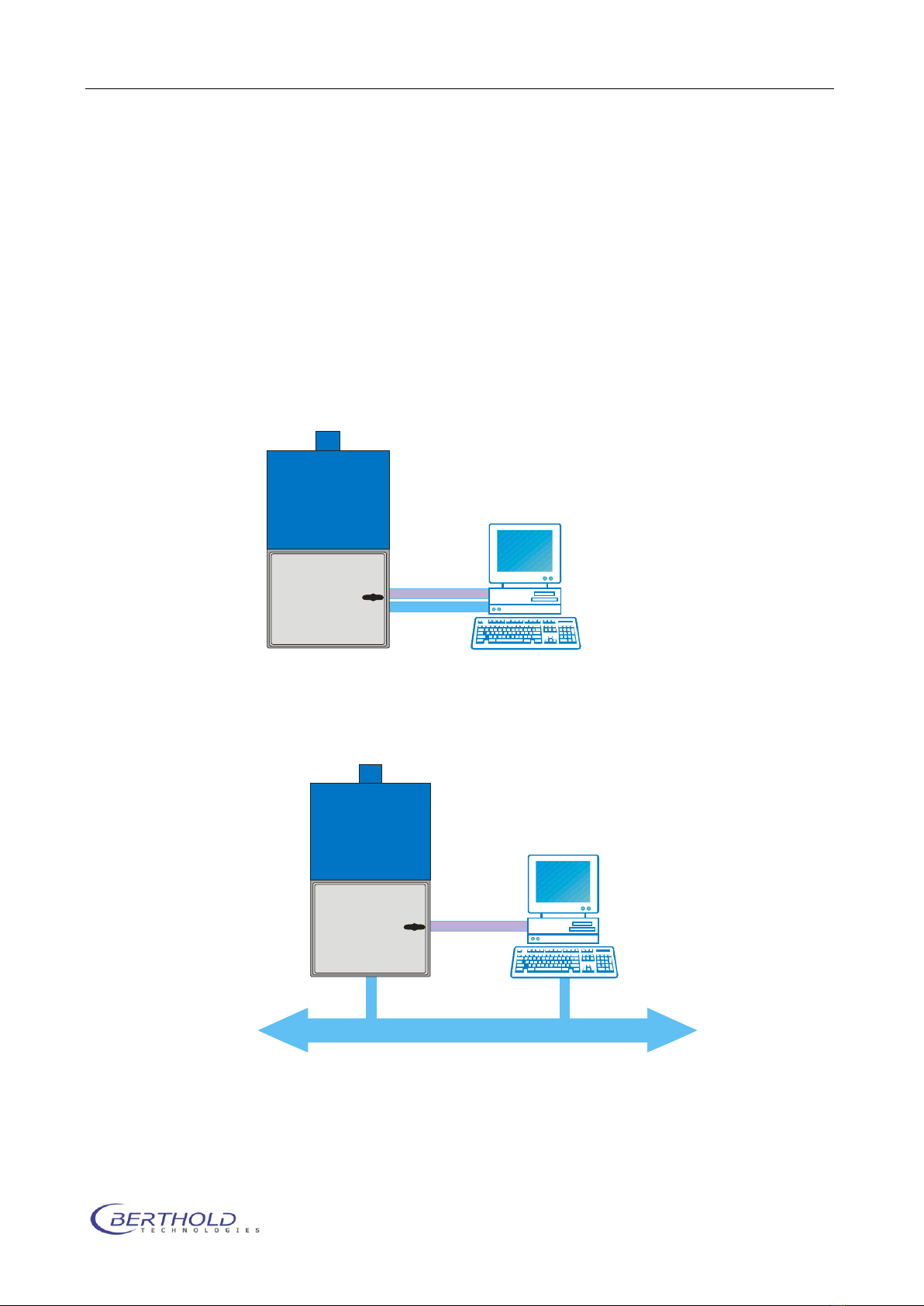

1.4 Connecting the PC (Ethernet)

The NightOWL camera transfers the image information using the

Ethernet bus. If the NightOWL is directly connected to the Ether-

net interface card of the PC, a so called “cross-over cable” is re-

quired (included with the shipment). This cable is plugged into

the network adapter on the PC, which is usually implemented on

the PC motherboard. If LAN access is required (internet, mail,

network printer) an additional network adapter (PCI, PCI Express

or USB) is required.

In case the NightOWL should be connected via LAN using the wall

socket or a network switch, a regular patch cable is needed.

Please keep the local IP address range in mind to avoid IP ad-

dress collisions. The direct connection between NightOWL and PC

is preferred.

To connect the NightOWL to the PC an Ethernet card with RJ-45

connectors is required. Most PCs have such a port already “on

board”. If not or if the network adapter is already in use, a regu-

lar PCI, PCI Express or USB network adapter (100 MBits) is re-

LAN

RS-232

Camera Control

Darkbox Control

LAN

RS-232

Camera Control

Darkbox Control

Installation NightOWL LB 983

1-4

quired. To install the network adapter, please refer to the corre-

sponding operation manual.

For a proper communication with the NightOWL, the IP address of

the PC must be set in the range of 192.168.1.xxx (except

192.168.1.117 -> default IP address of the NightOWL camera).To

setup the IP address of the PC, please refer to the manual of the

used operating system.

1.5 Connecting the PC (USB)

The USB version is easier to connect. Just use the supplied USB-

cable to connect the NightOWL to the PC.

After switching on the NightOWL the PC is recognizing new devic-

es and asks for drivers. The required drivers (camera and USB <-

> serial converter) are located on the installation CD in the

/drivers subdirectory.

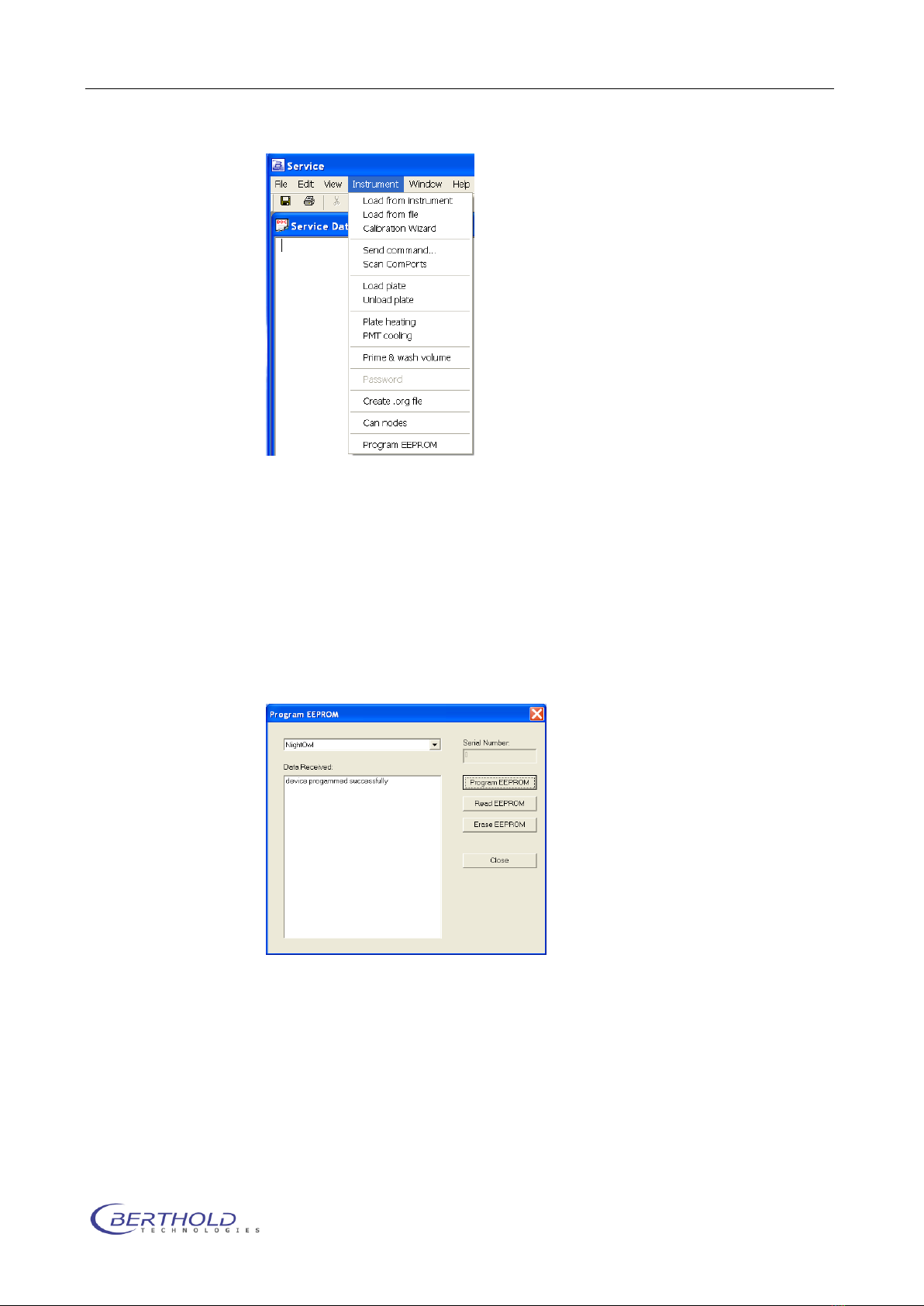

1.6 USB Mode programming

When a NightOWL II was used with WinLight and the user wants

to upgrade to indiGO the mode of the USB communication must

be changed.

WinLight used the internal USB to serial converter in native mode.

That means the internal EEPROM of the converter chip was not

programmed specially. When plugging in the NightOWL it was de-

tected as USB to Serial converter. Using indiGO the communica-

tion mode was changed which requires the programming of the

EEPROM. This is done using the service software. Before running

the service software, make sure the following entries are in the

service.ini file:

[Settings]

ProgramEEprom=1

[EEprom2]

Manufacturer=BertholdTech

ManufacturerId=BT

Description=NightOwl

SerialNumber=BT040508

ProductId=0xB5F2

NightOWL LB 983 Installation

1-5

This mode requires the use of specifically modified Berthold Tech-

nologies drivers. Otherwise the device driver cannot be installed

successfully because of a different vendor ID of the USB device.

Run the service software and scan the com port to identify the

NightOWL (with not programmed EEPROM). If found select the

NightOWL entry in the found instruments list and select “Program

EEPROM” from the “Instrument” menu.

The programming dialog box will pop up. Click on “Read EEPROM”

to check if the communication is OK and the chip is not pro-

grammed.

When the readout was successful select the NightOWL from the

list of devices and click on “Program EEPROM”.

A successful programming is confirmed in the text area (device

programmed successfully). Now the NightOWL is programmed

and after power cycling the instrument (switch off, wait 5 se-

conds, switch on) the device will be identified as (Berthold Tech-

nologies NightOWL). In addition a NightOWL Serial Port is used to

be compatible with the WinLight software.

Installation NightOWL LB 983

1-6

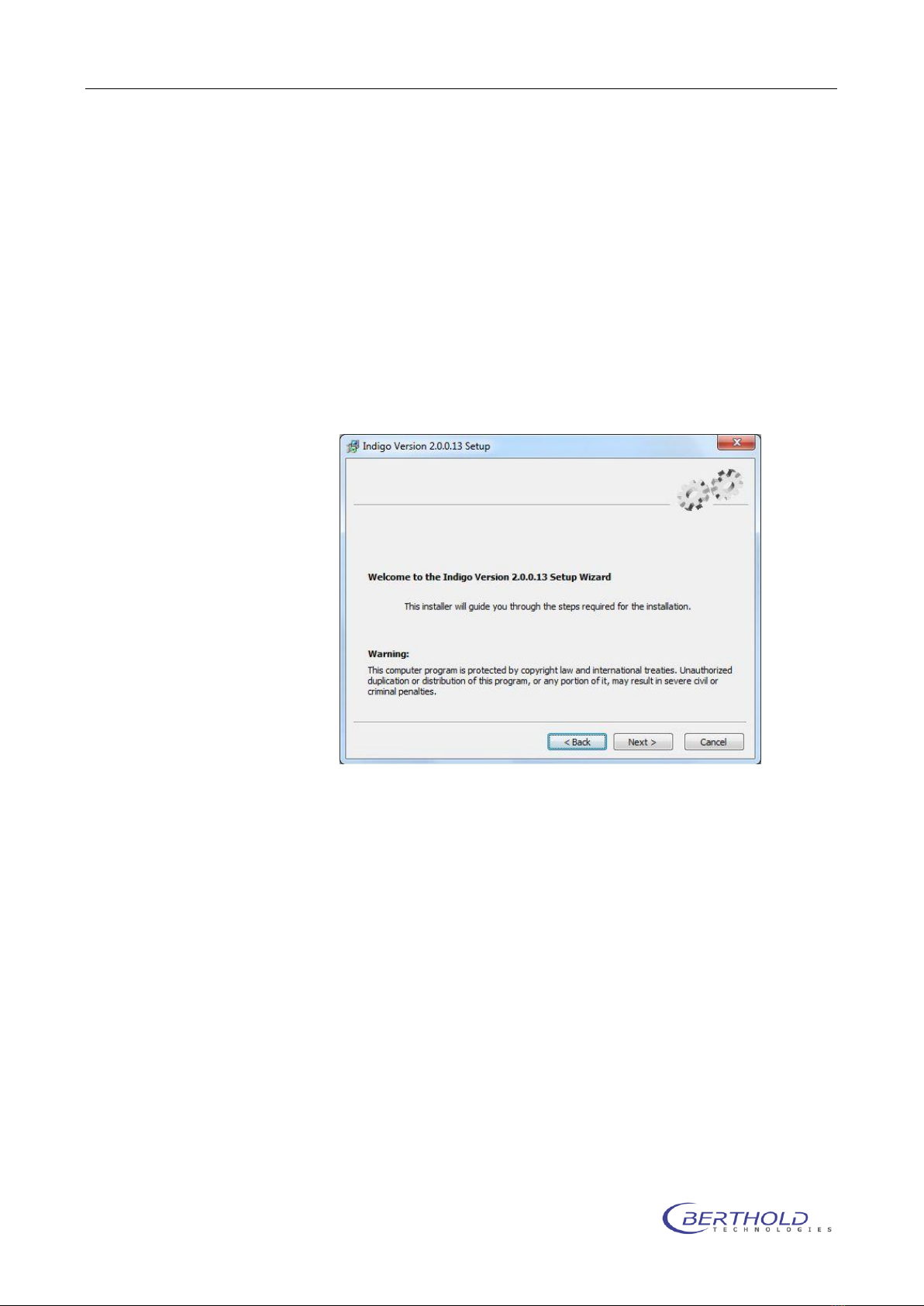

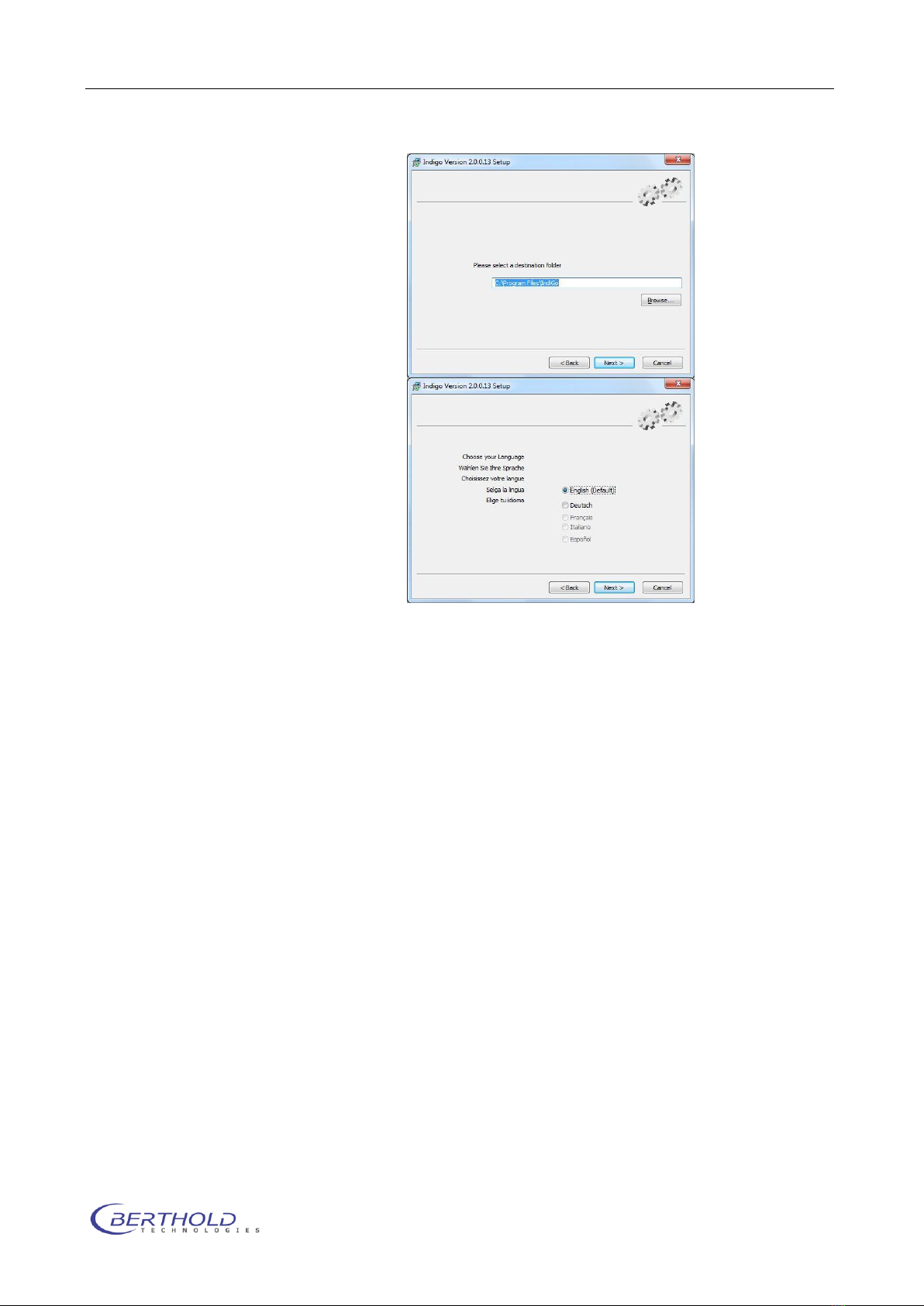

1.7 Software installation (indiGO)

The indiGO software is included on the enclosed USB stick or CD.

Keep this media in a secure place. You will need it again for pro-

gram updates or new installation.

For the operation of the NightSHADE the indiGO software version

2.00 or higher is necessary.

We recommend using Windows XP SP3 or Windows 7 as operating

system. Older operating systems are not supported.

To start the installation program Click on the file SETUP.EXE on

the data carrier. After launching the installation program a wel-

come screen appears:

After the welcome screen the folder for the software installation

must be defined. If possible confirm the suggested folder.

To get to the next screen asking for the language of the indiGO

user interface (at them moment only English available) click on

[Next]

NightOWL LB 983 Installation

1-7

Depending on the hardware you use a default se-

lection of system filters might be available and can

be installed through the setup. If you want to in-

stall the default filters tick the box “Install de-

fault filters”.

In this case the default systems filter management

file will be copied to your computer. If you reinstall

the software the current active systems filter

management file will be overwritten.

Note: Since the setup will install virtual device

drivers for the NightShade hardware on your com-

puter the Windows-system might show a warning

that a signature of a Windows driver cannot be

verified. In this case allow the setup to install

these Windows drivers.

Important Note: To install these drivers and the software, you

need administrator privileges.

indigo is only tested on WinXP/Vista Windows7 32 bit systems.

Installation NightOWL LB 983

1-8

1.8 Shipping instructions

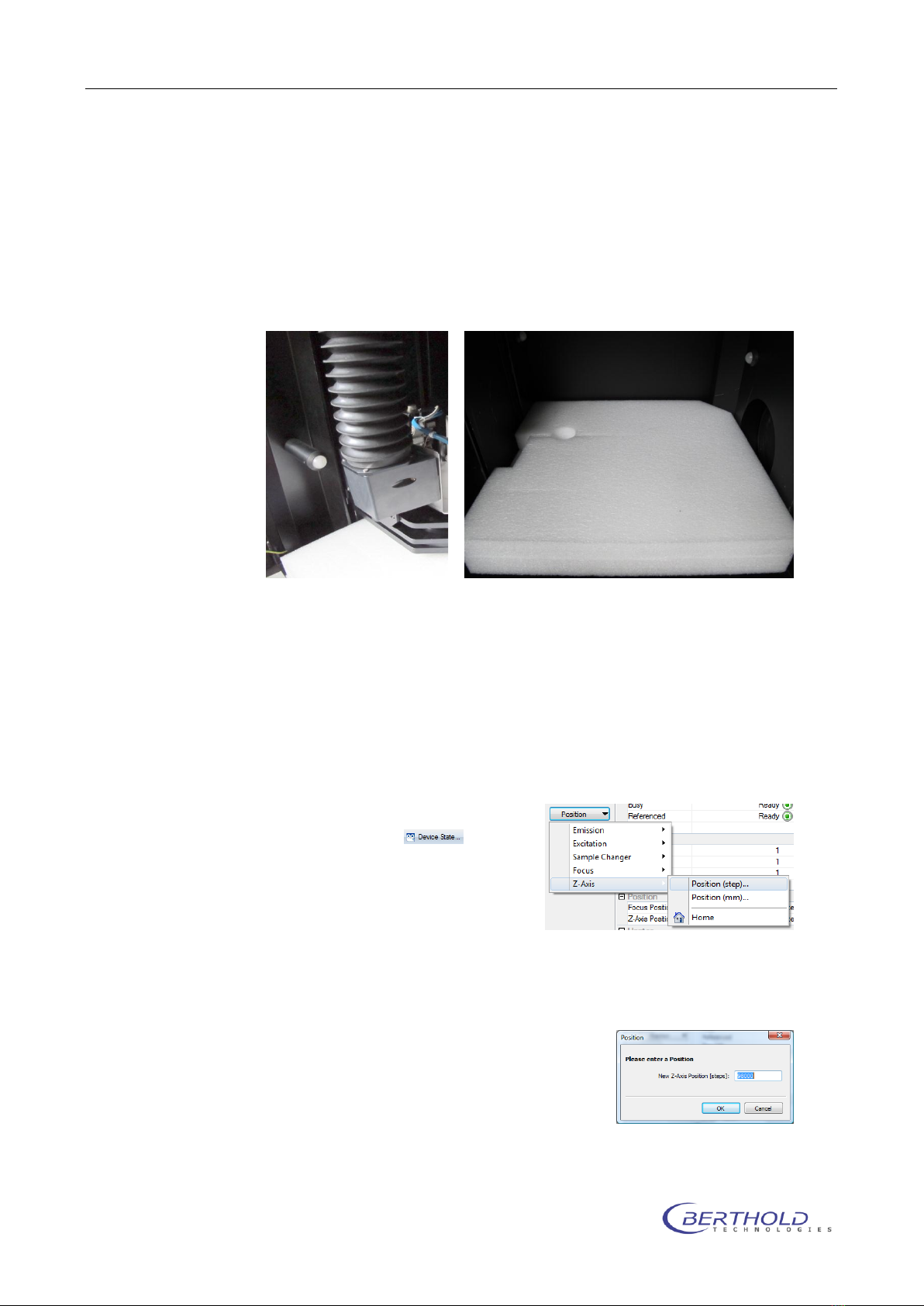

The NightOWL II must be shipped with the camera removed and

the foam piece laid on the bottom plate fixed with the camera lift

as shown on Figure 2:

Figure 2 Transport

holder

Proceed as follows:

Remove all filters from the filter wheel (empty wheel

mounted) and other accessories from the instrument and

place the foam piece on the base plate as shown in Figure

1

Move the camera (z-axis) into the low position (step

98000) using the ser-

vice software or indiGO.

Klick on , select

Position and choose Z-

Axis and Position from

the dropdown menu.

Enter 98000 steps at

the prompt and press

OK to move the camera to the shipping position.

The camera drive will block the foam piece and locks the

base plate.

Switch off the NightOWL II and do

not turn it on again since it will

move back to the home posi-

tion.

Remove the air adapters from the

camera, open the 2 thumb

Figure 1 foam piece

NightOWL LB 983 Installation

1-9

screws left and right of the camera, unplug the USB cable

and Power supply and carefully take out the camera.

Fix the transport holder for the air adapters as shown on

Figure 3. Use the grey spacers to avoid touching the lens.

Clip the air adapters to the

holder so that they are mag-

netically fixed.

Remove the power supply cable

from the instrument and place it

in the camera box.

Unscrew the noise killer at the

top rear side of the NightOWL

and place it in the camera box.

Close the front door and put the

NightOWL in the flight case. Close all Butterfly locks

Make sure that the blank transport flange without gas con-

nectors is mounted because the NightOWL will not fit into

the box with gas flange. Watch the position of the flange in

the flight case (recess). See Figure 4

Figure 4 NightOWL in flight case

Figure 3 fixing screw

with spacer

Calibration NightOWL LB 983

2-10

2. Calibration

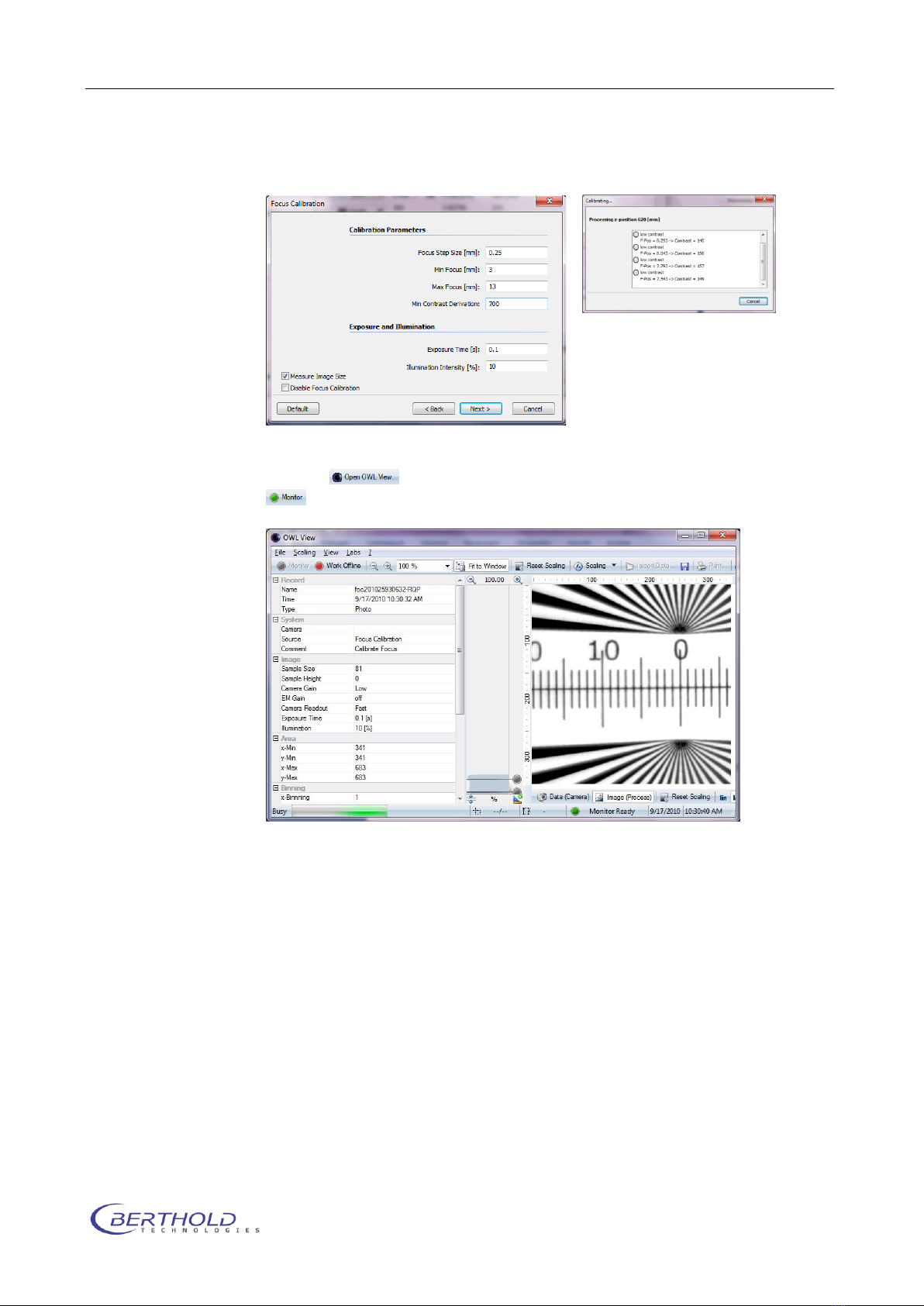

2.1 Focus calibration

To run the focus calibration a focus target is required. This sheet

can be found at the end of this document. When printing out the

focus target make sure, the scale shown on the target is really

20cm as this will be used in the calibration.

Cut the left border off and place the focus target on the bottom

plate that the center of the star is in the center of the image.

Right click on the indigo instrument controller and login (setup)

as service user (login: “onki”; password “onki”). The backend of

indiGO will show up:

To run the focus calibration click on the item “Focus Table” in the

Calibration section. The current focus table will show up.

A new calibration will be performed by clicking on

Use the default settings as shown below. The calibration proce-

dure starts after clicking on

NightOWL LB 983 Calibration

2-11

To see the live calibration images, launch The OWLview Tool from

indiGO and enable the monitor mode by clicking on the

icon. Modify the scaling if required to see details. The whole

procedure will take 10 to 15 minutes.

In case of contrast problems modify the contrast deviation or the

illumination intensity. It is also possible to recalibrate a single po-

sition in the focus table. To do so right click the desired position

and select “recalibrate” from the list.

In order to “fine tune” the calibration it might be useful to rerun

the calibration a second time using a smaller focus step size to

get better precision in the large scale images.

Calibration NightOWL LB 983

2-12

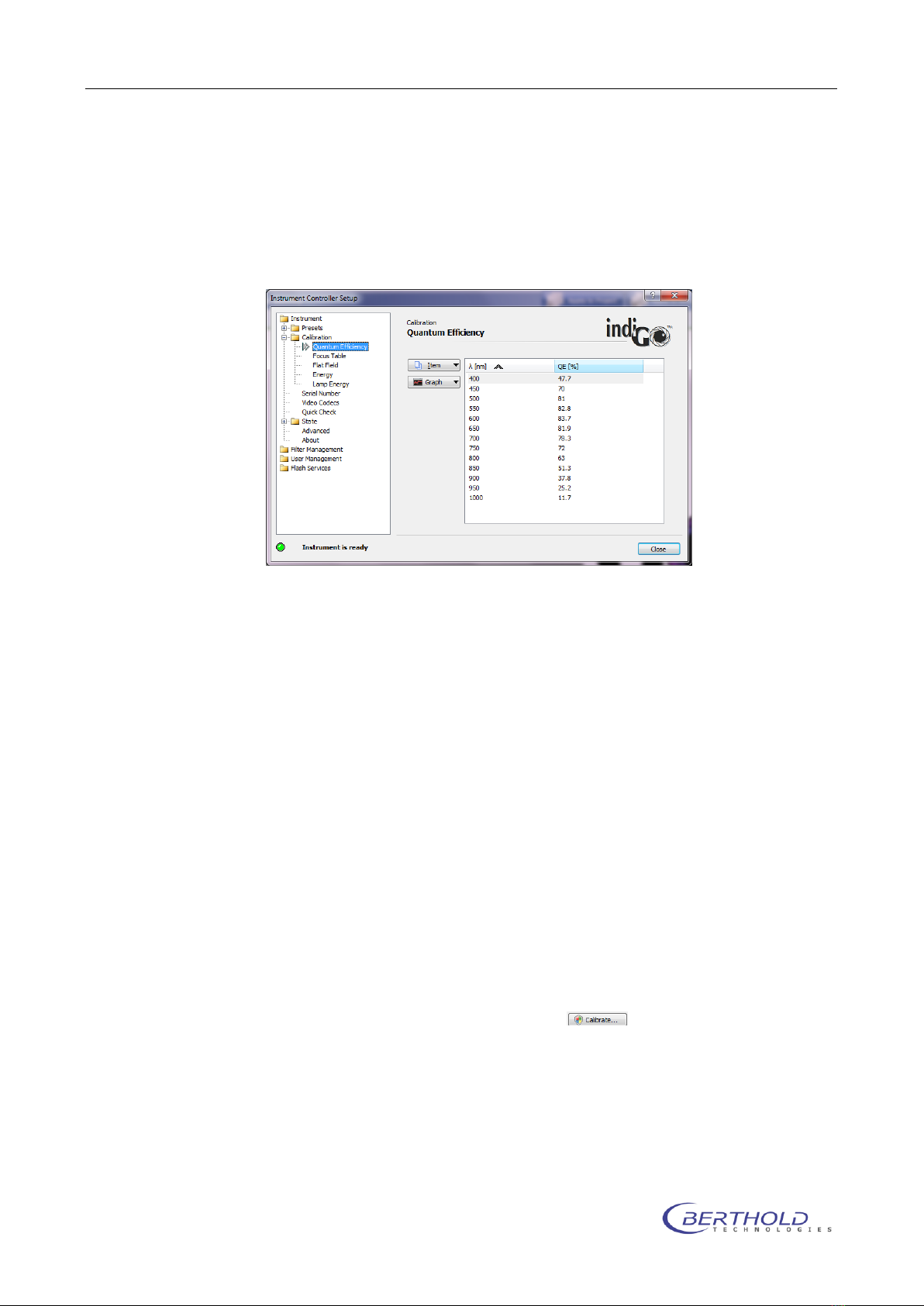

2.2 Quantum Efficiency

The quantum efficiency table describes the spectral efficiency of

the CCD chip. The table can be accessed by selecting “Quantum

Efficiency” from the Calibration section.

Depending on the camera used, this table might be different.

When using a NC 100 camera the quantum efficiency table should

look like as shown in the image. If no quantum efficiency entries

are shown, import the default values for the system (instrument

ID number –packet number) using the “Import configuration”

function in the “State - Advanced” section.

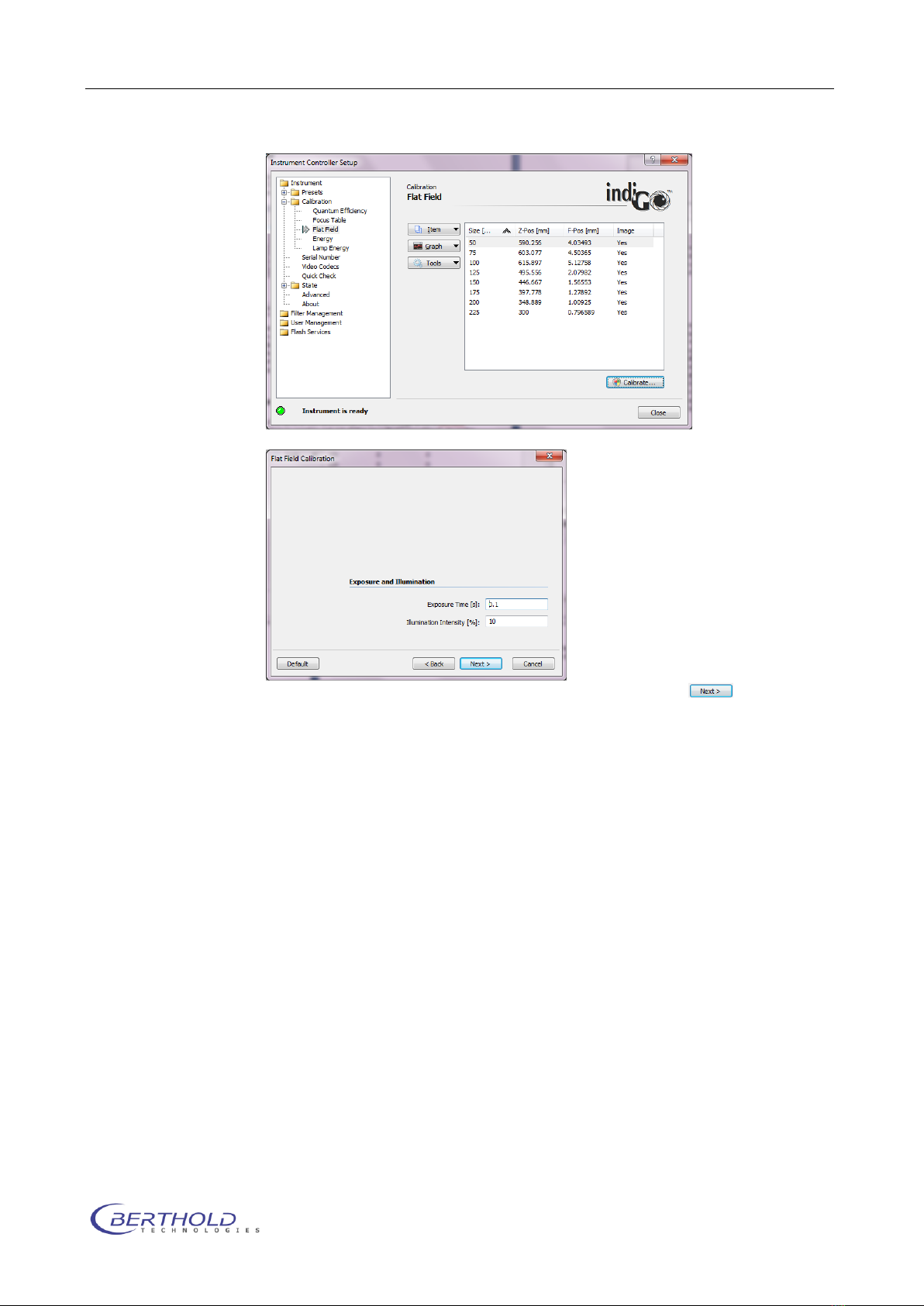

2.3 Flat field calibration

Since the lens is not uniform all over the image area a flatfield

correction is used to get rid of the so called “vignetting”. In order

to run the flat field calibration a clean white sheet of paper or

plastic is required (size min 270 x 270mm).

Place the white sheet on the bottom plate that the whole image

area is covered by the sheet.

To access the calibration, click on “Flat Field” in the calibration

section.

Start the calibration by clicking on . The standard parame-

ters should be used:

NightOWL LB 983 Calibration

2-13

The calibration procedure starts after clicking on

During the flat field calibration the system takes a photo of the

white sheet in the positions listed in the table and creates a flat

field correction curve.

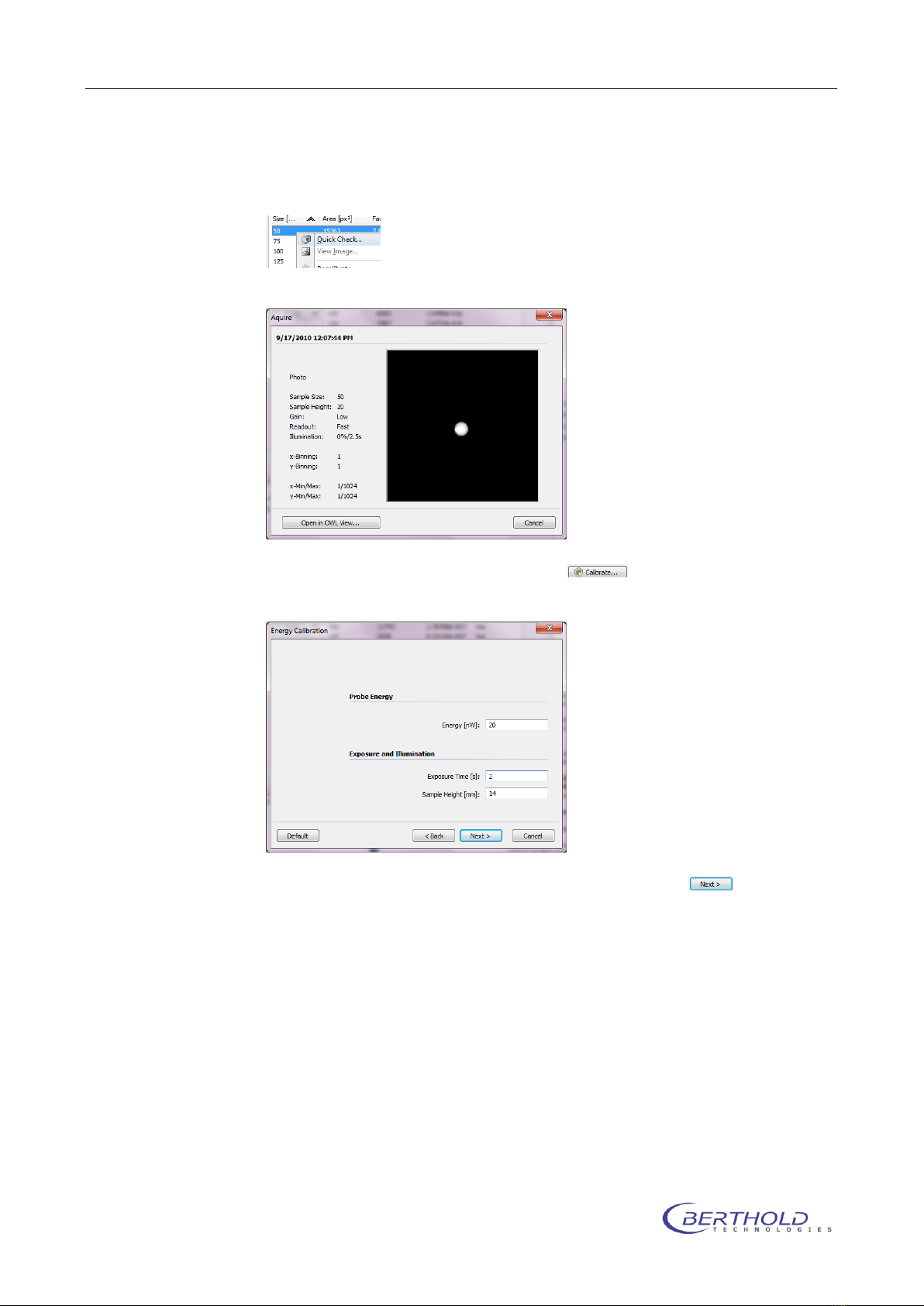

2.4 Energy Calibration

The NightOWL camera is movable to allow large as well as small

image sizes without moving the sample. Without energy calibra-

tion the intensity measured with the NightOWL might be different

at high and low positions due to physical rules. To compensate

this, an energy calibration must be performed. A calibration light

Standard with known light intensity (ID 29687) is required to run

the energy calibration.

The light standard is supplied by the CAN-connectors located at

the rear right side inside the dark box. The standard must be

placed on the base plate so that the white overload well (E9) is

centered in the image.

Calibration NightOWL LB 983

2-14

To check the positioning, select the item in the list with the small-

est sample size, right click and select “Quick Check”.

The sample should be positioned like this:

Start the calibration by clicking on . The standard parame-

ters should be used:

The calibration procedure starts after clicking on

The Berthold light standards are adjusted and certified to 20nW.

During the energy calibration the system takes images of the

light standard in the positions listed in the table and creates an

energy correction curve.

Check the calibtration images after the procedure using “View

Image” from the context menu if the exposure was not over-

range. Use a shorter exposure time if required (1s, 500ms). The

signal of the strongest image should be around 10000cts.

NightOWL LB 983 Calibration

2-15

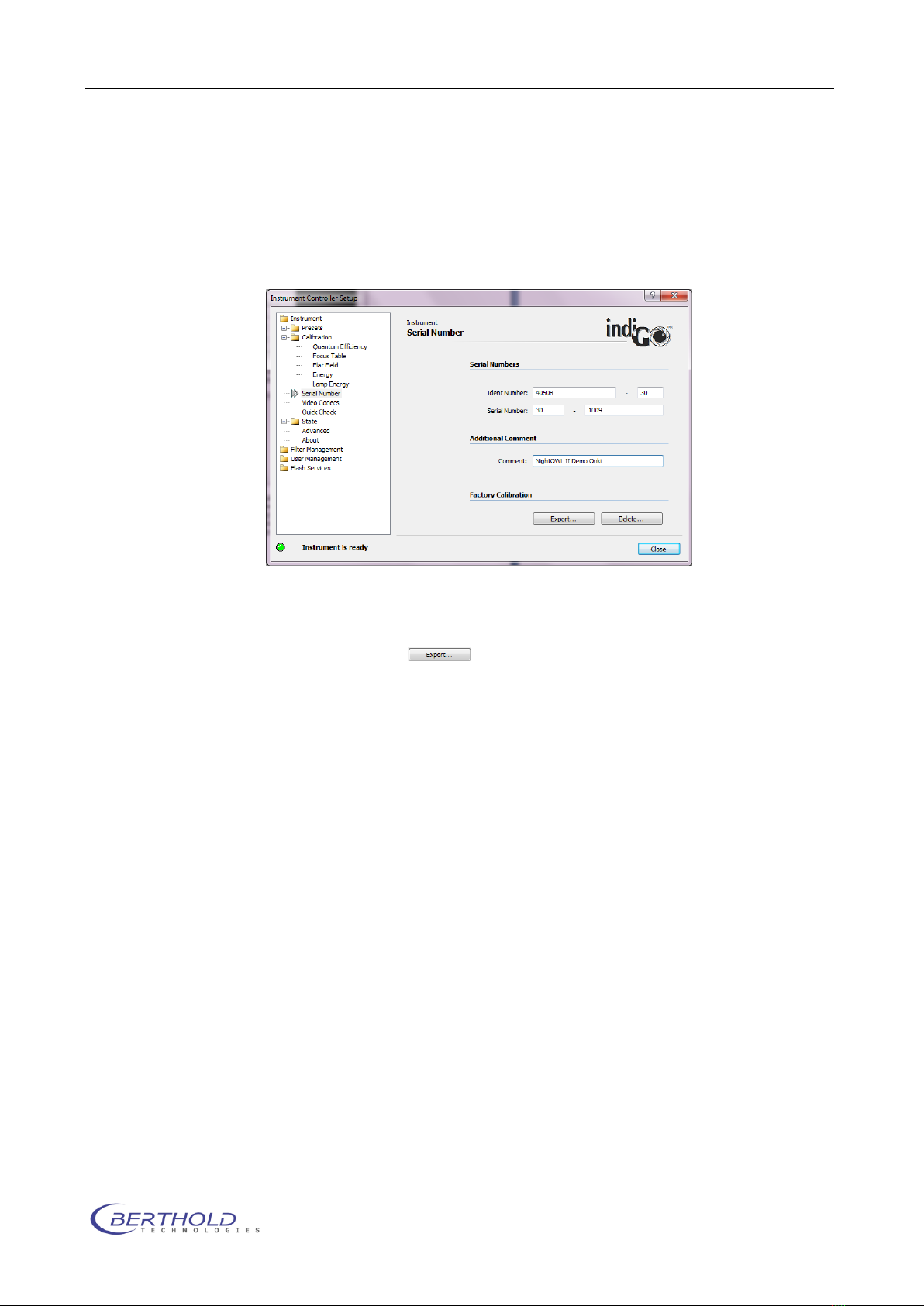

2.5 Calibration data

When all calibrations are done the calibration and configuration

data must be backed up to an external storage device (USB

Stick). This can be done in the Serial function of the Calibration

section.

Fill in the instrument ID number, packet number and serial num-

ber and click on to copy the calibration and configuration

data to a memory stick. Select the destination on the upcoming

dialog.

Store the memory stick in a safe location. Loosing this data re-

quires a new calibration in case of a new software installation.

The calibration data is stored in the /owlctrl/data subdirectory of

the program data directory. In Windows XP this folder can be

found in C:\Documents and Settings\All Users\Application Data.

In Vista and Windows 7 the program data is located in

C:\Program Data.

2.6 Other Data Files

In the /owlCtrl/data directory other configuration files are located

as well. The function is explained below.

owlCtrl.usr –This file contains all registered users. Do not

modify.

owlCtrl.flt –Filter configuration for excitation and emission.

owlCtrl.cdc –Video codecs list for video file creation.

Calibration NightOWL LB 983

2-16

owlCtrl.trc –Communication Protocol file. Might be useful

to send in case of any instrument/communication prob-

lems.

Indigo.net –User data and web update information. Do not

modify update information if not instructed since online up-

date might not work after modification.

owlCtrl.cnf –Contains the entire hardware configuration

and calibration oft he current system. This file is being re-

named after the import of the original file (e.g. 040508-30-

1010.cnf.

In folder /cdrv some default configuration files are located

in case of a new calibration or when no dedicated calibra-

tion file is available.

Table of contents

Other Berthold Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual