Rev. 01 Desiccant Flex Dryer DFD Side 1 af 40

1.0 CONTENTS........................................................................................................... 1

2.0 GENERAL INFORMATION........................................................................... 2

2.1 Application............................................................................................................................ 2

2.2 Restrictions ........................................................................................................................... 2

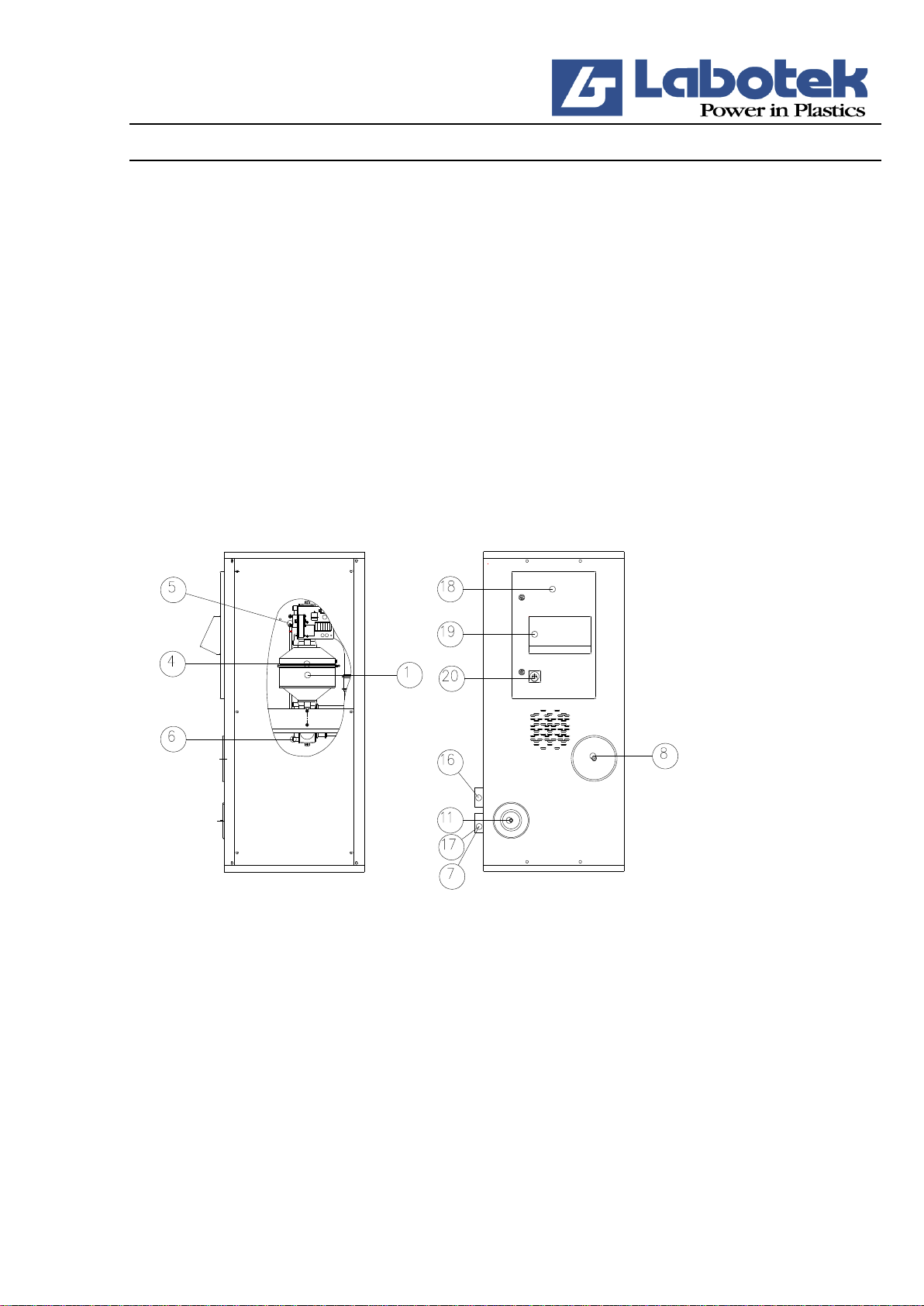

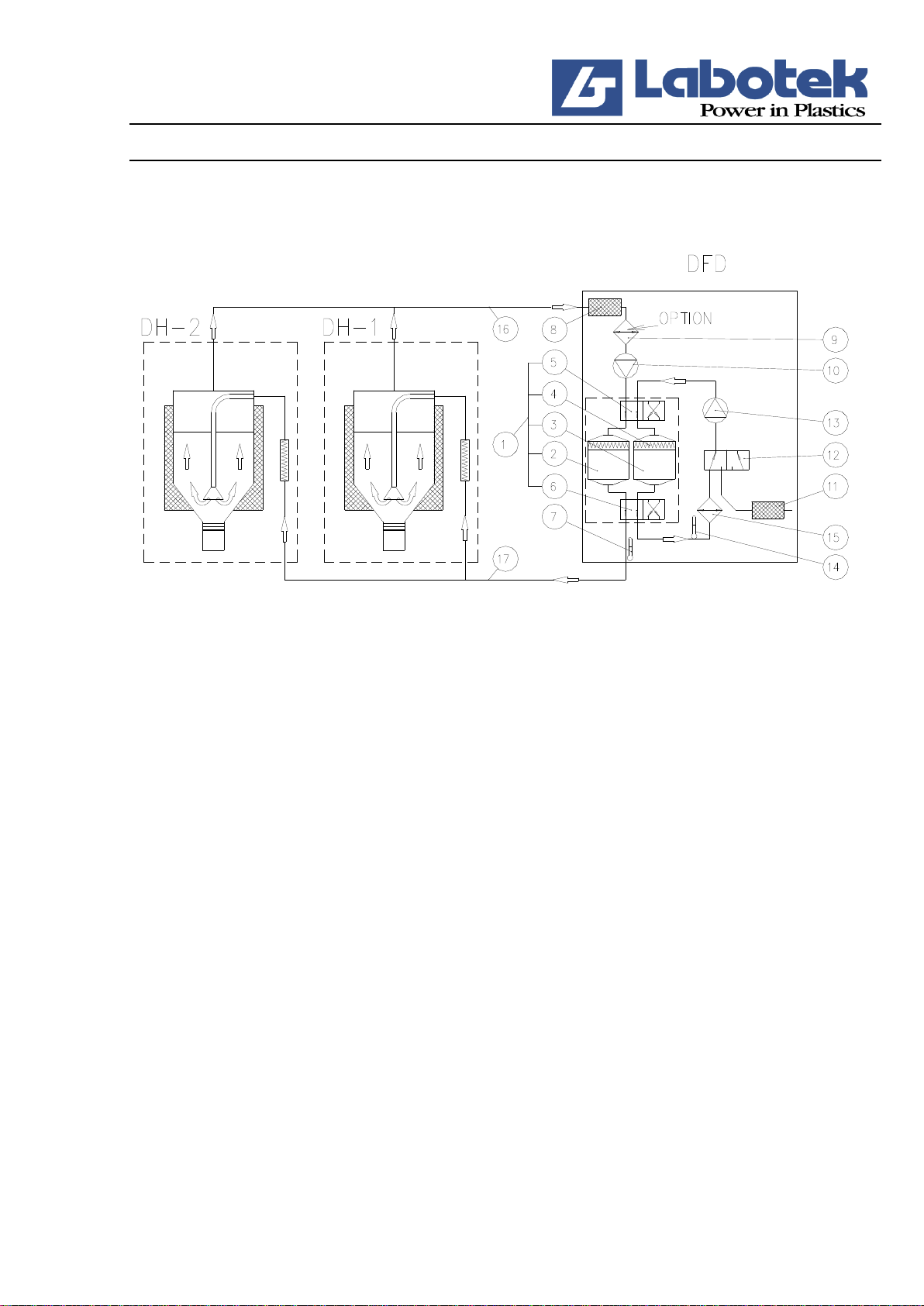

2.3 Design................................................................................................................................... 3

2.4 Relevant directives................................................................................................................ 4

2.5 Operating principles.............................................................................................................. 4

2.6 Certificates............................................................................................................................ 6

3.0 TECHNICAL DATA......................................................................................... 8

3.1 Technical specifications........................................................................................................ 8

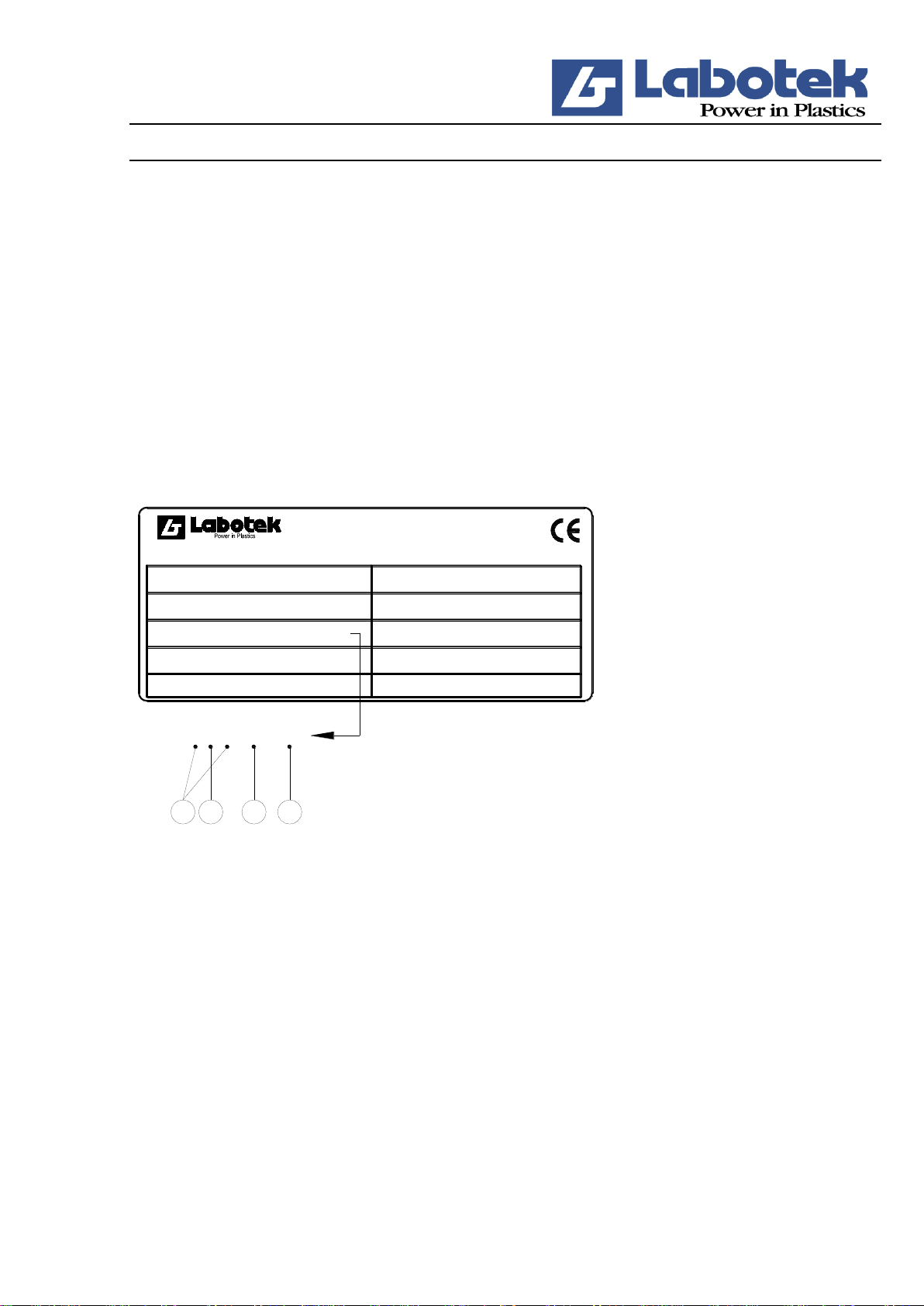

3.2 Typeplate .............................................................................................................................. 9

3.3 Dimensioned drawings ....................................................................................................... 10

3.4 Capacity table ..................................................................................................................... 11

3.5 Safety measures .................................................................................................................. 11

3.6 Noise level .......................................................................................................................... 12

4.0 INSTALLATION/OPERATION...................................................................12

4.1 Packing and transport.......................................................................................................... 12

4.2 Installation/connection........................................................................................................ 12

OPERATING THE SYSTEM..................................................................................14

5.1 Operating - LAB DRY........................................................................................................ 14

6.0 TROUBLESHOOTING .....................................................................................29

6.1 Machine gives en error message......................................................................................... 30

7.0 MAINTENANCE............................................................................................. 31

7.1 Maintaining the desiccant bed ............................................................................................ 31

7.2 Maintaining the air filters ................................................................................................... 31

7.3 Cleaning/checking the regeneration cooler......................................................................... 32

8.0 REPAIRS.......................................................................................................... 33

8.1 Replacing the desiccant bed assembly................................................................................ 33

8.2 Replacement of balls in the valve unit................................................................................ 36

8.3 Replacement of the motor for the change-over valve......................................................... 38

8.4 Replacement of blowers...................................................................................................... 39

8.5 Replaceing the fresh air valve............................................................................................. 40