SAFETY & OPERATIONAL PRECAUTIONS

See Additional Safety Precautions included with the Electrical Control Box Installation Information

Always consider electrical shock hazard when working with and handling electrical equipment. If

uncertain, consult an Electrician. Electrical wiring should only be done by a qualified Electrician, per

Local and State Electrical Codes.

For proper performance do NOT modify, substitute nozzle, hose diameter or electrical control box.

Manufacturer assumes no liability for the use or misuse of this unit.

Wear protective clothing, gloves and eye wear when working with chemicals.

Always direct the discharge away from people and electrical devices.

Follow the chemical manufacturer's safe handling instructions.

NEVER mix chemicals without first consulting chemical manufacturer.

Disconnect electrical power to the control box prior to opening it.

TO INSTALL (REFER TO DIAGRAM ON NEXT PAGE)

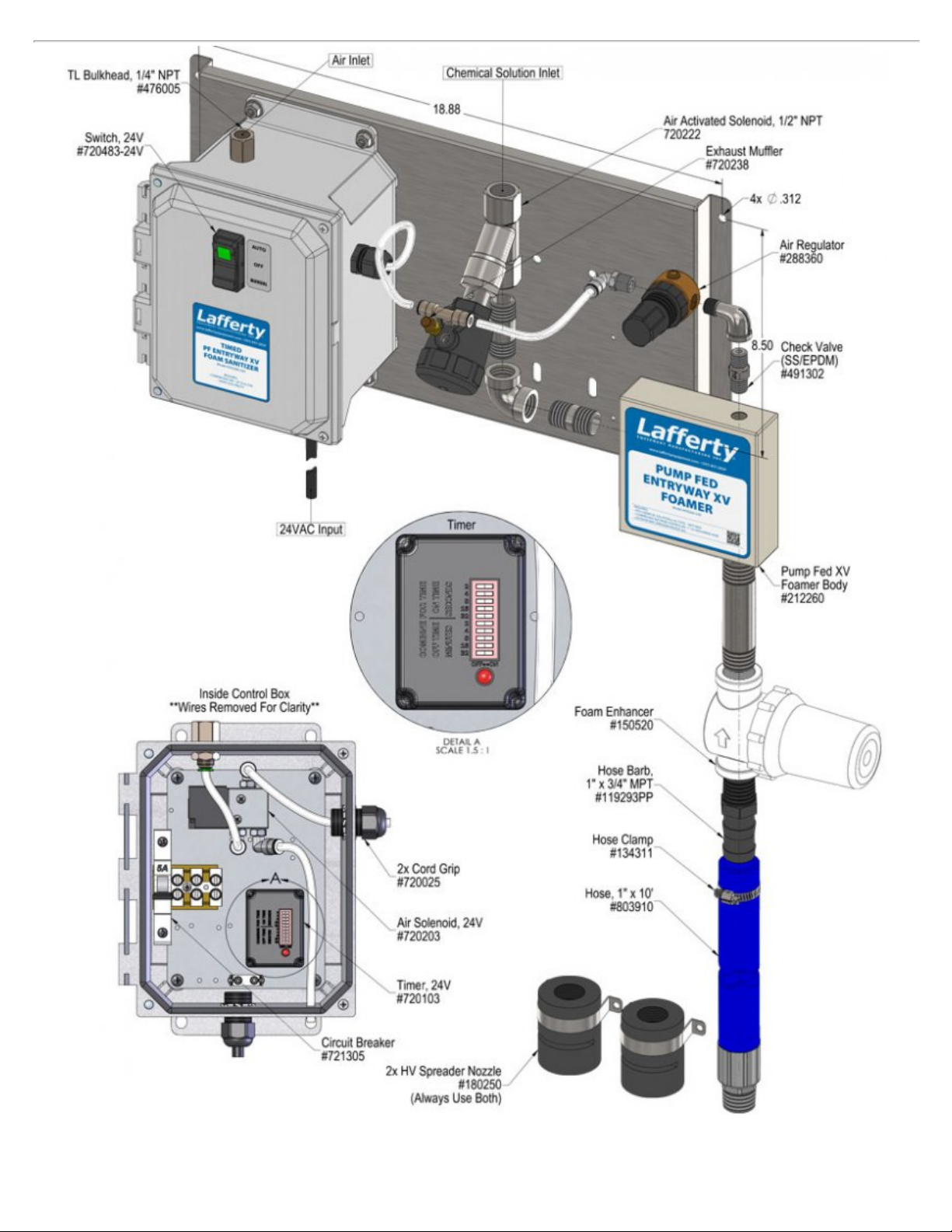

Illustration on Page 1 shows overall system setup. Refer to companion instructions for control box upgrades.

1. Install foam enhancer to entryway foamer discharge. The arrow on the foam enhancer should point UP -

opposite the flow direction.

2. Mount the unit to a suitable surface near the entryway

3. Frame the doorway with 3/4" ID piping (not included), as shown in the illustration on Page 1.

4. Mount the spreader nozzle slots 5-6" off the floor, a little higher for wider entryways. Use both nozzles.

5. Connect the unit to the 3/4" pipe frame using the provided 10' hose (1" ID) and 1" ID piping. Each nozzle should

be the same distance from the connection between 1" and 3/4" piping to ensure simultaneous activation. Use as

few elbows as possible. Hose/pipe ID is very important.

6. Connect chemical solution supply - a solution check valve is recommended.

7. Connect compressed air to the unit.

TO OPERATE

TO TEST

1. This unit requires 24VAC electrical input - a customer supplied standard step-down transformer is required.

2. Connect the 24VAC output from the transformer to the electrical input to the control box.

3. Plug the transformer into the wall electrical outlet.

4. The unit has been tested and the timer is preset to run for 60 seconds to allow for final adjustments. (ON TIME

will activate first.) Open your chemical solution supply valve and your air supply valve, and then turn on the power

switch.

5. Final air adjustments will now have to be made.

6. Wait a few seconds and observe foam consistency.

Use the least amount of air needed to achieve good foam quality to prevent water pressure fluctuations

from affecting performance. Air pressure must be kept lower than water pressure.

To adjust foam consistency pull out on the air regulator knob, turn slightly clockwise for dryer foam and

counterclockwise for wetter foam. Wait a few seconds to see each adjustment.

Once desired foam consistency is achieved push lock the knob. You are ready to start.

TIMER ADJUSTMENT

1. CAUTION! UNPLUG THE POWER CORD! Then open control box and adjust the timer. The ON TIME dip

switches control how long the foam will be applied. The OFF TIME dip switches control how long the unit will stay

off between foam applications. Add up the seconds for each activated dip switch to arrive at the desired duration

of the ON cycle. Usually 8-10 seconds is sufficient to foam the floor (longer plumbing runs will require a longer

application cycle). Add up the minutes for each activated dip switch to arrive at the desired duration of the OFF

cycle. Set your OFF TIME to maintain the foam’s presence according to your flow (anywhere from 6 to 15

minutes).

2. Close control box and plug in the power cord. Turn on the power switch. The unit will now function according to

the timer settings. (ON TIME will activate first.)

Note: The unit will run 24 hours a day unless the power switch is manually turned off.

For extra foam at any time, press and hold the lower end (Momentary control) of the door switch. (See

Switch Settings, below.)

SWITCH SETTINGS

Automatic control – Top of switch is depressed. Green light glows.

OFF – Switch is in middle position; green light is off

Momentary control – Press bottom of switch. Unit is active only while switch is pressed. When released, the

switch returns to the OFF position.

UNIT FLOW RATES

PSI GPM

35 3.74

40 4.00

50 4.47

60 4.90

70 5.29

80 5.66

90 6.00

100 6.32

976260-24V • Timed PF Entryway XV Foam Sanitizer - 24VAC

- Page 2 -